Export orders last month dropped by 12.8 percent to US$35.31 billion, the biggest annual decline in seven years, the Ministry of Economic Affairs said yesterday, blaming the decrease to slipping orders for information and communications technology (ICT) products.

Following a short-lived recovery in December last year, export orders for ICT products contracted last month by 17 percent year-on-year to US$9.7 billion due to declining orders of smartphones, laptops and servers.

“We also have to take into account that there were six fewer working days last month [than in January last year] due to the Lunar New Year holiday,” Department of Statistics Director Huang Yu-ling (黃于玲) told a news conference in Taipei.

As more than 90 percent of ICT products are produced overseas, mainly in China, the COVID-19 outbreak might further affect production and undercut orders this month, she said.

“We expect the outbreak to affect between US$3 billion and US$3.5 billion of export orders this month,” Huang said, adding that about 80 percent of that amount would come from orders of ICT products.

Orders for electronics, which make up nearly one-third of the nation’s overall export orders, last month posted a relatively mild decline of 1.3 percent to US$10.3 billion, ministry data showed.

“The market for consumer electronics has entered a traditionally weak season, resulting in a smaller number of orders for suppliers,” Huang said.

Nonetheless, growing demand for foundry services and ICs propelled by upcoming 5G deployments helped cushion the fall in electronics orders, she said.

Orders of optoelectronics last month plummeted 18.8 percent to US$1.54 billion and the value might drop further this month due to supply chain disruptions as a result of the outbreak in China, Huang said, citing a government survey of optoelectronics makers.

In non-tech industries, export orders of base metals products; machinery equipment; rubber and plastic products; and chemicals all fell last month amid negative global market sentiment, the data showed.

However, those industries are expected to show annual growth in orders of between 9.7 percent and 14.9 percent this month due to a relatively low comparison base, Huang said.

To assist disease-affected manufacturers, the ministry has proposed budgeting an additional NT$3.47 billion (US$114.7 million) in funds, Industrial Development Bureau Director-General Richard Leu (呂正華) said.

The ministry has also looked at expanding the criteria for firms to be considered eligible to participate in government programs encouraging investment in the nation, he said.

Similar to a program aimed at assisting small and medium-sized enterprises initiated last week, the ministry has proposed an interest rate reduction of 1.06 percent for loans to local manufacturers and plans to allocate about NT$946 million to subsidize their interest payments, he added.

“We would also subsidize manufacturers that seek to sharpen their competitive edge through investment in innovation,” Leu said, adding that free courses would also be offered to companies’ employees.

Mercuries Life Insurance Co (三商美邦人壽) shares surged to a seven-month high this week after local media reported that E.Sun Financial Holding Co (玉山金控) had outbid CTBC Financial Holding Co (中信金控) in the financially strained insurer’s ongoing sale process. Shares of the mid-sized life insurer climbed 5.8 percent this week to NT$6.72, extending a nearly 18 percent rally over the past month, as investors bet on the likelihood of an impending takeover. The final round of bidding closed on Thursday, marking a critical step in the 32-year-old insurer’s search for a buyer after years of struggling to meet capital adequacy requirements. Local media reports

US sports leagues rushed to get in on the multi-billion US dollar bonanza of legalized betting, but the arrest of an National Basketball Association (NBA) coach and player in two sprawling US federal investigations show the potential cost of partnering with the gambling industry. Portland Trail Blazers coach Chauncey Billups, a former Detroit Pistons star and an NBA Hall of Famer, was arrested for his alleged role in rigged illegal poker games that prosecutors say were tied to Mafia crime families. Miami Heat guard Terry Rozier was charged with manipulating his play for the benefit of bettors and former NBA player and

TECHNOLOGICAL RIVALRY: The artificial intelligence chip competition among multiple players would likely intensify over the next two years, a Quanta official said Quanta Computer Inc (廣達), which makes servers and laptops on a contract basis, yesterday said its shipments of artificial intelligence (AI) servers powered by Nvidia Corp’s GB300 chips have increased steadily since last month, should surpass those of the GB200 models this quarter. The production of GB300 servers has gone much more smoothly than that of the GB200, with shipments projected to increase sharply next month, Quanta executive vice president Mike Yang (楊麒令) said on the sidelines of a technology forum in Taipei. While orders for GB200 servers gradually decrease, the production transition between the two server models has been

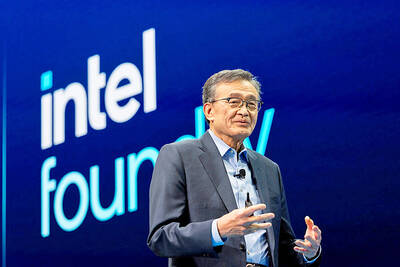

BETTER THAN EXPECTED: The firm’s Q3 results exceeded its projections, based on ‘the underlying strength of our core markets,’ chief financial officer Dave Zinsner said Intel Corp returned to profitability and gave an upbeat revenue forecast after PC demand grew, suggesting that it is making progress on a long and challenging comeback attempt. In the third quarter, revenue rose 3 percent to US$13.7 billion. The Santa Clara, California-based company posted its first quarterly net income since the end of 2023, with earnings per share of US$0.23, excluding some items. Analysts had estimated sales of US$13.2 billion and earnings per share of US$0.01 on average, according to data compiled by Bloomberg. Fourth-quarter sales would be roughly US$13.3 billion, the company said in a statement on Thursday. Intel shares gained about