Plastics are everywhere. Whether used to store leftovers, keep hospital equipment sterile or insulate a home, plastics are unmatched for their adaptability, durability and low cost. Given their seemingly boundless benefits, it is not surprising that plastics have replaced traditional materials in many sectors — for example, steel in cars, paper and glass in packaging, and wood in furniture. As a result, annual plastics consumption worldwide has increased from 5 million tonnes in the 1950s to about 280 million tonnes today.

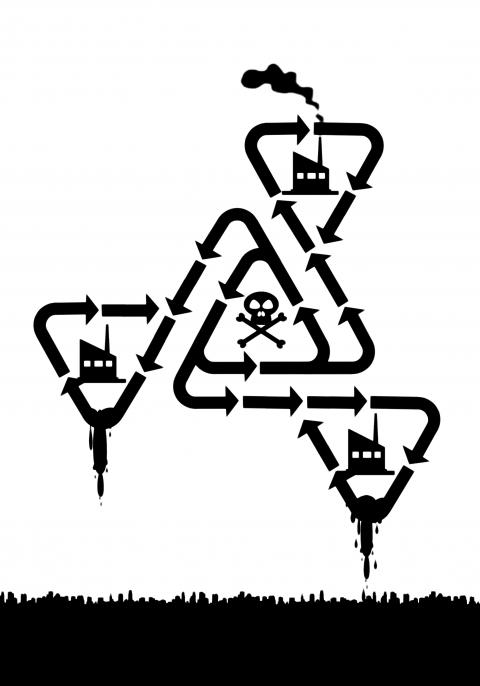

Roughly half of plastic products, such as packaging, are intended for one-time, short-lifespan (less than six months) applications prior to disposal. Given that most of these items are not biodegradable, and are not recycled, plastics waste is building up — with serious environmental consequences. While governments have begun to implement new (and often quite strict) regulations aimed at managing plastics waste — for example, China banned lightweight plastic shopping bags in 2008 — they are inadequate to address the world’s growing plastics-waste problem.

Moreover, most plastic products are made from so-called “petroleum-based commodity thermoplastics.” Given that a non-renewable resource forms the basis of many plastic products — most of which will not last long — current plastics usage patterns are not sustainable.

Closed-loop recycling, in which plastics waste is used to make another product, therefore carries significant environmental benefits, such as reduced energy and oil consumption.

However, the process of separating the petroleum-based recyclable plastics from other kinds of plastics and solid waste is difficult, costly and labor-intensive, so only a small proportion is recycled.

In 1988, the US Society of Plastics Industry (SPI) developed a coding system in which each kind of resin is labeled with a number, 1 to 7, to facilitate sorting. The system has also been used elsewhere, including in Canada and Switzerland, but has not been adopted worldwide and is still confusing to some consumers. If people knew how to collect and separate household plastics based on their number, when available, the resulting boost to recycling efforts would demonstrate to government and industry the viability of a more sustainable approach, reduce exposure to rising oil prices and support growing global demand for plastics.

There are four categories of plastics recycling: Primary recycling, in which the plastic is reused in the same application; secondary recycling, in which material (mixed or contaminated) is used in less demanding applications; tertiary recycling, in which the plastic is converted into monomers or chemicals; and quaternary recycling, in which only energy is recovered through incineration.

Each of these methods recovers a different amount of the embodied energy of the plastic item. (All of the embodied energy is lost if the plastics are landfilled, a common disposal method worldwide.)

Given the difficulty and expense of separating plastics, the most economically viable option is often secondary recycling of a few commodity thermoplastics — mostly bottles, for which collection infrastructure is already in place. More economical separation methods are crucial to expanding the scope of plastics recycling, as is the identification of new potential markets for the recyclates.

Such developments would encourage industry to reuse or recycle more parts.

Although all 40 kinds of plastics used in a US automobile can be recycled, the need to separate and clean them makes using them more expensive than using virgin plastic resins. This translates to a higher proportion of plastics in the remnants of shredded end-of-life automobiles — a contaminated mixture of plastics and non-plastics that is usually disposed of through some combination of landfilling, incineration and secondary recycling.

Increasing the proportion of reused plastics is a crucial step toward more sustainable plastics consumption. To this end, some automobile manufacturers have adjusted their designs to allow for easy disassembly of parts made of compatible plastics, while governments have set recycling target proportions for end-of-life vehicles. Such efforts should be intensified.

Furthermore, industry should seek new applications for recycled materials, while minimizing the amount of virgin material used, and, where possible, manufacturers should “down-gauge” materials (make parts thinner).

Government legislation can be enacted to support such measures, as well as to require plastics manufacturers to get involved in the disposal of plastic items — a responsibility long imposed on packaged-goods manufacturers in Europe.

An example of successful waste management is the reprocessing of PET bottles (made of polyethylene terephthalate) into polyester fibers.

In the last decade, Japan passed several laws obliging both businesses and individuals to separate plastics waste. This, combined with a lack of landfill space and the country’s expanding population, has enhanced plastics recycling efforts.

As a result, in 2010 Japan recycled 72 percent of PET bottles, compared to about 30 percent in the US and 48 percent in Europe. While incineration and landfilling are still practiced, such high recycling rates underscore the positive impact of targeted policies.

Another promising development is bioplastics, which have begun to compete with petroleum-based products in certain short-lifespan applications — such as packaging and agriculture — over the last two decades.

Given that bioplastics are produced from renewable or “bio-based” sources (cellulose, starch, and glucose) — and, in some cases, through microbial fermentation — they have a lower carbon footprint, contribute less to global warming, and biodegrade to small molecules.

However, bioplastics are not a silver bullet for managing plastics waste. In fact, they may threaten the secondary recycling of petroleum-based plastics, owing to possible contamination during sorting of mixed streams.

Critics have expressed concern about the environmental impact of corn and other crops grown for industrial purposes, such as plastics and ethanol production, not to mention the potential effects on global food prices.

In a world that is reliant on plastics, more sustainable production, consumption, and disposal of plastic products is crucial. Civil society, industry and government must work together to increase the share of recycled plastics, thereby ensuring that plastics’ costs do not outweigh their benefits.

Marino Xanthos is professor of Chemical, Biological and Pharmaceutical Engineering at the New Jersey Institute of Technology.

Copyright: Project Syndicate

Recently, China launched another diplomatic offensive against Taiwan, improperly linking its “one China principle” with UN General Assembly Resolution 2758 to constrain Taiwan’s diplomatic space. After Taiwan’s presidential election on Jan. 13, China persuaded Nauru to sever diplomatic ties with Taiwan. Nauru cited Resolution 2758 in its declaration of the diplomatic break. Subsequently, during the WHO Executive Board meeting that month, Beijing rallied countries including Venezuela, Zimbabwe, Belarus, Egypt, Nicaragua, Sri Lanka, Laos, Russia, Syria and Pakistan to reiterate the “one China principle” in their statements, and assert that “Resolution 2758 has settled the status of Taiwan” to hinder Taiwan’s

Singaporean Prime Minister Lee Hsien Loong’s (李顯龍) decision to step down after 19 years and hand power to his deputy, Lawrence Wong (黃循財), on May 15 was expected — though, perhaps, not so soon. Most political analysts had been eyeing an end-of-year handover, to ensure more time for Wong to study and shadow the role, ahead of general elections that must be called by November next year. Wong — who is currently both deputy prime minister and minister of finance — would need a combination of fresh ideas, wisdom and experience as he writes the nation’s next chapter. The world that

Can US dialogue and cooperation with the communist dictatorship in Beijing help avert a Taiwan Strait crisis? Or is US President Joe Biden playing into Chinese President Xi Jinping’s (習近平) hands? With America preoccupied with the wars in Europe and the Middle East, Biden is seeking better relations with Xi’s regime. The goal is to responsibly manage US-China competition and prevent unintended conflict, thereby hoping to create greater space for the two countries to work together in areas where their interests align. The existing wars have already stretched US military resources thin, and the last thing Biden wants is yet another war.

Since the Russian invasion of Ukraine in February 2022, people have been asking if Taiwan is the next Ukraine. At a G7 meeting of national leaders in January, Japanese Prime Minister Fumio Kishida warned that Taiwan “could be the next Ukraine” if Chinese aggression is not checked. NATO Secretary-General Jens Stoltenberg has said that if Russia is not defeated, then “today, it’s Ukraine, tomorrow it can be Taiwan.” China does not like this rhetoric. Its diplomats ask people to stop saying “Ukraine today, Taiwan tomorrow.” However, the rhetoric and stated ambition of Chinese President Xi Jinping (習近平) on Taiwan shows strong parallels with