The threat from the 2019 novel coronavirus outbreak on Thursday closed in on the global auto industry, as Fiat Chrysler Automobiles NV warned that a European plant could shut down within two to four weeks if Chinese parts suppliers cannot get back to work.

The next several weeks will be critical for automakers. Parts made in China are used in millions of vehicles assembled elsewhere, and China’s Hubei Province, epicenter of the outbreak, is a major hub for vehicle parts production and shipments.

Industry experts have said that auto suppliers had built up a cushion of parts in inventory and in-transit ahead of the Lunar New Year holiday, but those would start to run out if Chinese parts factories cannot get back to work next week, or if flights to and from China remain limited.

Chinese auto parts and assembly plants have extended previously planned New Year’s shutdowns through Monday next week, but some have pushed the shutdowns out further.

“Almost everybody has some product where they are in trouble,” said Dan Hearsch, a managing director for the auto and industrial practice of consulting firm AlixPartners.

Fiat Chrysler could be forced to suspend production at a European assembly plant if parts do not begin to arrive within two to four weeks, chief executive officer Mike Manley said on Thursday, without identifying the plant or vehicles at risk.

South Korea’s Hyundai said that shortages of parts from China would force it to suspend production at its South Korean plants.

Other global automakers have not disclosed details about potential disruptions outside China, but have said that they are monitoring the risks.

Toyota operating officer Masayoshi Shirayanagi said that the automaker is “looking very closely at inventories of components” outside China.

GM has teams working around the clock to head off trouble, the automaker’s chief financial officer said.

Automakers are more likely than in the past to have backup sources of critical parts, AlixPartners consultant Hearsch said.

They and their major suppliers took steps after the deadly 2011 tsunami that crippled key auto parts makers in Japan to reduce the risk that a catastrophe at a single factory could shut down assembly lines, Hearsch added.

Flexible manufacturing equipment can also be reprogrammed or relocated to produce parts. When a fire at a Michigan supplier plant threatened production of Ford Motor Co’s high-profit pickup trucks, Ford moved rapidly to relocate production tools to a plant in Ontario.

Still, not all the production from China’s Hubei Province can be easily replaced or moved.

Hubei is one of 11 Chinese provinces that are responsible for more than two-thirds of vehicle production in China, IHS Markit said in a study last week.

If plants remain idle into next month, the production losses within China would become significant, amounting to more than 1.7 million vehicles of lost production during the first quarter, IHS projected.

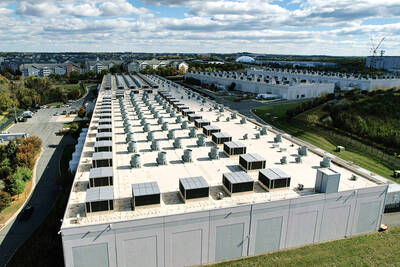

The demise of the coal industry left the US’ Appalachian region in tatters, with lost jobs, spoiled water and countless kilometers of abandoned underground mines. Now entrepreneurs are eyeing the rural region with ambitious visions to rebuild its economy by converting old mines into solar power systems and data centers that could help fuel the increasing power demands of the artificial intelligence (AI) boom. One such project is underway by a non-profit team calling itself Energy DELTA (Discovery, Education, Learning and Technology Accelerator) Lab, which is looking to develop energy sources on about 26,305 hectares of old coal land in

Taiwan’s exports soared 56 percent year-on-year to an all-time high of US$64.05 billion last month, propelled by surging global demand for artificial intelligence (AI), high-performance computing and cloud service infrastructure, the Ministry of Finance said yesterday. Department of Statistics Director-General Beatrice Tsai (蔡美娜) called the figure an unexpected upside surprise, citing a wave of technology orders from overseas customers alongside the usual year-end shopping season for technology products. Growth is likely to remain strong this month, she said, projecting a 40 percent to 45 percent expansion on an annual basis. The outperformance could prompt the Directorate-General of Budget, Accounting and

Netflix on Friday faced fierce criticism over its blockbuster deal to acquire Warner Bros Discovery. The streaming giant is already viewed as a pariah in some Hollywood circles, largely due to its reluctance to release content in theaters and its disruption of traditional industry practices. As Netflix emerged as the likely winning bidder for Warner Bros — the studio behind Casablanca, the Harry Potter movies and Friends — Hollywood’s elite launched an aggressive campaign against the acquisition. Titanic director James Cameron called the buyout a “disaster,” while a group of prominent producers are lobbying US Congress to oppose the deal,

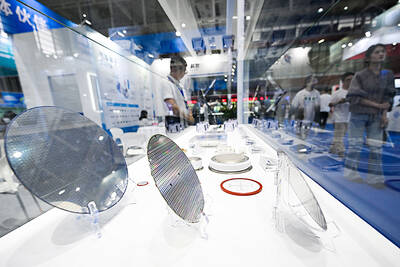

Two Chinese chipmakers are attracting strong retail investor demand, buoyed by industry peer Moore Threads Technology Co’s (摩爾線程) stellar debut. The retail portion of MetaX Integrated Circuits (Shanghai) Co’s (上海沐曦) upcoming initial public offering (IPO) was 2,986 times oversubscribed on Friday, according to a filing. Meanwhile, Beijing Onmicro Electronics Co (北京昂瑞微), which makes radio frequency chips, was 2,899 times oversubscribed on Friday, its filing showed. The bids coincided with Moore Threads’ trading debut, which surged 425 percent on Friday after raising 8 billion yuan (US$1.13 billion) on bets that the company could emerge as a viable local competitor to Nvidia