Matsushita Electric Industrial Co, which makes consumer electronics under the Panasonic brand, will produce semiconductors for digital cameras in Singapore, the first time such products will be manufactured outside Japan.

Matsushita Electric, the world's largest maker of consumer electronics, said it will spend S$50 million (US$29 million) to start production of the chips, known as charge-coupled devices, which are in demand because of the popularity of digital cameras and cell phones that incorporate cameras.

Matsushita Electric, one of four makers of the digital camera chips, all of which are Japanese, said it is setting up production in Singapore to be closer to customers who are moving assembly lines to countries such as China and Malaysia.

Demand for the chips outstrips supply, said Matsushita vice president Yukio Furuta.

"It is really tremendous growth that we anticipate," Furuta said at a press conference in Singapore. "The market is growing so fast."

Matsushita Electric shares fell ?1 to ?1,489 as of 1:50pm in Tokyo. The shares have risen 27 percent this year.

The Osaka-based Matsushita Electric aims to double sales of charge-coupled devices in the year ending March to almost ?40 billion (US$342 million).

In Singapore, the company will test, assemble and ship the chips, originally manufactured in Japan. Matsushita Electric, which was the first chipmaker from Japan to open a plant in Singapore 24 years ago, plans to add about 400 workers to its semiconductor workforce of 738 in the next three to five years as it raises production.

Digital camera chips will account for 30 percent of semiconductor production for Matsushita Electric in Singapore within five years. The unit generated sales of S$238 million last fiscal year.

Matsushita Electric's move is good news for the electronics sector in Singapore, which accounts for 50 percent of the country's manufacturing and has been losing out on new investments from companies such as Maxtor Corp, which is building a new factory in China.

Singapore's government said last month that investment in new factories and equipment will fall to S$7.5 billion this year, less than its S$8 billion target. Spending reached S$9.01 billion last year.

Matsushita will also spend S$100 million to expand production of chips for DVD and CD players, and will shift manufacturing of less-advanced chips made in Singapore to Indonesia and Malaysia.

DEMOGRAPHICS: Robotics is the most promising answer to looming labor woes, the long-term care system and national contingency response, an official said Taiwan is to launch a five-year plan to boost the robotics industry in a bid to address labor shortages stemming from a declining and aging population, the Executive Yuan said yesterday. The government approved the initiative, dubbed the Smart Robotics Industry Promotion Plan, via executive order, senior officials told a post-Cabinet meeting news conference in Taipei. Taiwan’s population decline would strain the economy and the nation’s ability to care for vulnerable and elderly people, said Peter Hong (洪樂文), who heads the National Science and Technology Council’s (NSTC) Department of Engineering and Technologies. Projections show that the proportion of Taiwanese 65 or older would

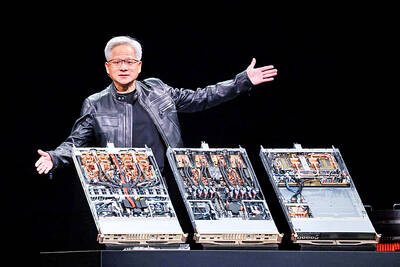

Nvidia Corp yesterday unveiled its new high-speed interconnect technology, NVLink Fusion, with Taiwanese application-specific IC (ASIC) designers Alchip Technologies Ltd (世芯) and MediaTek Inc (聯發科) among the first to adopt the technology to help build semi-custom artificial intelligence (AI) infrastructure for hyperscalers. Nvidia has opened its technology to outside users, as hyperscalers and cloud service providers are building their own cost-effective AI chips, or accelerators, used in AI servers by leveraging ASIC firms’ designing capabilities to reduce their dependence on Nvidia. Previously, NVLink technology was only available for Nvidia’s own AI platform. “NVLink Fusion opens Nvidia’s AI platform and rich ecosystem for

Taiwan Semiconductor Manufacturing Co (TSMC, 台積電) yesterday said it is building nine new advanced wafer manufacturing and packaging factories this year, accelerating its expansion amid strong demand for high-performance computing (HPC) and artificial intelligence (AI) applications. The chipmaker built on average five factories per year from 2021 to last year and three from 2017 to 2020, TSMC vice president of advanced technology and mask engineering T.S. Chang (張宗生) said at the company’s annual technology symposium in Hsinchu City. “We are quickening our pace even faster in 2025. We plan to build nine new factories, including eight wafer fabrication plants and one advanced

‘WORLD’S LOSS’: Taiwan’s exclusion robs the world of the benefits it could get from one of the foremost practitioners of disease prevention and public health, Minister Chiu said Taiwan should be allowed to join the World Health Assembly (WHA) as an irreplaceable contributor to global health and disease prevention efforts, Minister of Foreign Affairs Lin Chia-lung (林佳龍) said yesterday. He made the comment at a news conference in Taipei, hours before a Taiwanese delegation was to depart for Geneva, Switzerland, seeking to meet with foreign representatives for a bilateral meeting on the sidelines of the WHA, the WHO’s annual decisionmaking meeting, which would be held from Monday next week to May 27. As of yesterday, Taiwan had yet to receive an invitation. Taiwan has much to offer to the international community’s