Her white-gloved, waistcoated uniform impeccable, 22-year-old Hazuki Okuno boards a bullet train replica to rehearse the strict protocols behind the smooth operation of a Japanese institution turning 60 Tuesday.

High-speed Shinkansen trains began running between Tokyo and Osaka on Oct. 1, 1964, heralding a new era for rail travel as Japan grew into an economic superpower after World War II.

The service remains integral to the nation’s economy and way of life — so keeping it dazzlingly clean, punctual and accident-free is a serious job.

Photo: AFP

At a 10-story, state-of-the-art staff training center, Okuno shouted from the window and signaled to imaginary colleagues, keeping her cool when a video screen down the platform showed a flailing passenger stuck in a door.

The live-in facility southwest of Tokyo offers what rail operator Central Japan Railway Co (JR Central) describes as an “intense education” for future conductors, drivers and other team members.

“Thank you for riding,” Okuno practiced saying, bowing deeply after checking the time on her watch.

Photo: AFP

Each day nearly one-quarter of a million passengers ride the Tokaido Shinkansen line, which stretches from Tokyo past Mount Fuji to Hakata, about five hours away.

One top-speed Nozomi train arrives up to every five minutes.

JR Central said it has never had an accident resulting in death or injury on the bullet train, even in a country where earthquakes, typhoons and heavy snow are common.

Photo: AFP

Safety is “our top priority,” JR Central public relations officer Daisuke Kumajima said. So “we take our education and training of our employees very seriously.”

This month for the first time, on another line run by East Japan Railway Co (JR East), two linked bullet trains uncoupled, resulting in an emergency stop, but no injuries.

With routes spanning the country, the Shinkansen’s top speed of 320kph is no longer the world’s fastest, having been outpaced by China.

However, the original high-speed locomotive’s streamlined nose and spacious interiors remain a symbol of Japanese engineering prowess and attention to detail.

It is also a tourist must-do and pop culture mainstay — such as in Brad Pitt’s 2022 blockbuster Bullet Train.

A meticulous maintenance schedule means the trains are gleaming outside and in, with cleaners adjusting headrests and using brushes to ensure the seats are free of crumbs.

In some countries, train delays leave little time for such primping, said Christopher Hood, author of the book Shinkansen: From Bullet Train to Symbol of Modern Japan.

On the bullet train network, the average delay is less than a minute.

The growth of cities along Shinkansen routes over the decades shows its effect on the economy in Japan, where “face-to-face business is very, very important,” added Hood, a researcher at Cardiff University in Wales.

In tandem, the train has played a role in speeding up depopulation in rural Japan, leaving many elderly people isolated, Hood said.

“People would rather live in the big cities ... and then use the Shinkansen to go and visit relatives out in smaller cities if they need to,” he said.

At a JR Central site, an engineer taps the inner machinery of a bullet train, listening closely for any unusual sounds that could reveal a loose part.

With aging Japan increasingly facing labor shortages, the company is also researching a new digital inspection system that can analyze images of a train to spot dangers.

Meanwhile, JR East has said that driverless bullet trains could be introduced from the mid-2030s.

There is also a huge project under way to build a high-speed magnetic levitation (maglev) line in Japan, long-delayed due to environmental opposition.

Maglev trains, which can run at 500kph, were meant to begin service between Tokyo and Nagoya in central Japan in 2027, but JR Central has pushed that back to 2034 or later.

The aim is to create a “dual system” with the Shinkansen to respond to demand and keep operations stable in the case of maintenance work or a major earthquake, Kumajima said.

It is easy to take the Shinkansen for granted in Japan, which is a good thing, Hood said.

However, when Japanese travel overseas, particularly in Europe or the US, “they soon appreciate that ‘yeah, the Shinkansen is a little bit special,’” he said.

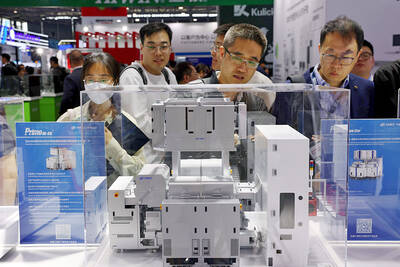

SEMICONDUCTOR SERVICES: A company executive said that Taiwanese firms must think about how to participate in global supply chains and lift their competitiveness Taiwan Semiconductor Manufacturing Co (TSMC, 台積電) yesterday said it expects to launch its first multifunctional service center in Pingtung County in the middle of 2027, in a bid to foster a resilient high-tech facility construction ecosystem. TSMC broached the idea of creating a center two or three years ago when it started building new manufacturing capacity in the US and Japan, the company said. The center, dubbed an “ecosystem park,” would assist local manufacturing facility construction partners to upgrade their capabilities and secure more deals from other global chipmakers such as Intel Corp, Micron Technology Inc and Infineon Technologies AG, TSMC said. It

EXPORT GROWTH: The AI boom has shortened chip cycles to just one year, putting pressure on chipmakers to accelerate development and expand packaging capacity Developing a localized supply chain for advanced packaging equipment is critical for keeping pace with customers’ increasingly shrinking time-to-market cycles for new artificial intelligence (AI) chips, Taiwan Semiconductor Manufacturing Co (TSMC, 台積電) said yesterday. Spurred on by the AI revolution, customers are accelerating product upgrades to nearly every year, compared with the two to three-year development cadence in the past, TSMC vice president of advanced packaging technology and service Jun He (何軍) said at a 3D IC Global Summit organized by SEMI in Taipei. These shortened cycles put heavy pressure on chipmakers, as the entire process — from chip design to mass

Germany is to establish its first-ever national pavilion at Semicon Taiwan, which starts tomorrow in Taipei, as the country looks to raise its profile and deepen semiconductor ties with Taiwan as global chip demand accelerates. Martin Mayer, a semiconductor investment expert at Germany Trade & Invest (GTAI), Germany’s international economic promotion agency, said before leaving for Taiwan that the nation is a crucial partner in developing Germany’s semiconductor ecosystem. Germany’s debut at the international semiconductor exhibition in Taipei aims to “show presence” and signal its commitment to semiconductors, while building trust with Taiwanese companies, government and industry associations, he said. “The best outcome

Semiconductor equipment billings in Taiwan are expected to double this year, as manufacturers in the industry are keen to expand production to meet strong global demand for artificial intelligence applications, according to SEMI, which represents companies in the electronics manufacturing and design supply chain. Speaking at a news conference before the opening of Semicon Taiwan trade show tomorrow, SEMI director of industry research and statistics Clark Tseng (曾瑞榆) said semiconductor equipment billings in Taiwan are expected to grow by an annual 100 percent this year, beating an earlier estimate of 70 percent growth. He said that Taiwan received a boost from a