Toyota Motor Corp and Contemporary Amperex Technology Co Ltd (CATL, 新能源科技), the world’s top battery maker, are closing plants in China’s Sichuan Province as a drought-induced power crisis worsens.

The Japanese automaker shut a factory in the provincial capital of Chengdu and would keep operations suspended until Saturday, company spokesperson Shiori Hashimoto said.

The Chengdu plant produces about 30,000 vehicles a year, including the Landcruiser Prado, the manufacturer’s Web site says.

Photo: Reuters

CATL halted activity at its major lithium battery base in the city of Yibin through the same date, a local business publication reported.

The company did not respond to an e-mailed request for comment.

The power cuts have affected more than 70 percent of steel mills in Sichuan, which have either halted production or started rationing, Mysteel said in a note this week.

Henan Zhongfu Industry Co (河南中孚), an aluminum smelter, is halting production for a week for some production units in Sichuan.

The Chinese price of aluminum is up about 3.5 percent since Monday’s close.

Sichuan, one of China’s most populous provinces, is highly reliant on hydropower. That makes it particularly vulnerable to a heat wave and drought that have pushed up air-conditioning demand and dried up reservoirs behind hydro dams. It is a key manufacturing hub and is also important for the production of materials, including polysilicon and lithium, that are vital to the energy transition.

The southwestern province has become a key development hub for battery makers aiming to harness hydropower to reduce emissions in their production processes.

CATL has about 100 gigawatts of existing and planned capacity in the province, the most after Fujian, according to BloombergNEF.

Volkswagen AG on Monday said its factory in Chengdu is affected by power shortages, but that it was only expecting slight delays in deliveries to customers. Foxconn Technology Co (富士康科技集團) also makes Apple iPads in the province, but said it was seeing only limited impact from the drought so far.

While other regions in China are dealing with curtailments on a smaller scale, a major power crisis is likely to be mostly limited to Sichuan because of its unique reliance on dams for electricity.

Many Chinese provinces rely more on coal for power, and generators stocked up on the fuel in the run-up to summer as COVID-19 lockdowns weighed on demand. The heat wave has reversed that, with coal consumption for the first two weeks of this month rising 15 percent from a year earlier, the government’s top planning agency said on Tuesday.

Temperatures in Chengdu yesterday were as high as 38oC after soaring above 40oC in parts of Sichuan on Tuesday, with humidity making it feel hotter.

Some office buildings in the city have stopped air-conditioning as the power shortage becomes more severe, Securities Times reported.

Sichuan is a major rice and corn producer, and the National Meteorological Center said this week the drought could damage crops and hinder growth.

The heat wave is not limited to just Sichuan and is affecting the wider Yangtze River basin. There is only light-to-moderate rain expected in the next week and the Three Gorges Dam, the world’s largest, in neighboring Hubei Province, would release more water in the next five days to help replenish the middle and lower reaches of China’s largest waterway, Xinhua news agency reported.

NOT JUSTIFIED: The bank’s governor said there would only be a rate cut if inflation falls below 1.5% and economic conditions deteriorate, which have not been detected The central bank yesterday kept its key interest rates unchanged for a fifth consecutive quarter, aligning with market expectations, while slightly lowering its inflation outlook amid signs of cooling price pressures. The move came after the US Federal Reserve held rates steady overnight, despite pressure from US President Donald Trump to cut borrowing costs. Central bank board members unanimously voted to maintain the discount rate at 2 percent, the secured loan rate at 2.375 percent and the overnight lending rate at 4.25 percent. “We consider the policy decision appropriate, although it suggests tightening leaning after factoring in slackening inflation and stable GDP growth,”

DIVIDED VIEWS: Although the Fed agreed on holding rates steady, some officials see no rate cuts for this year, while 10 policymakers foresee two or more cuts There are a lot of unknowns about the outlook for the economy and interest rates, but US Federal Reserve Chair Jerome Powell signaled at least one thing seems certain: Higher prices are coming. Fed policymakers voted unanimously to hold interest rates steady at a range of 4.25 percent to 4.50 percent for a fourth straight meeting on Wednesday, as they await clarity on whether tariffs would leave a one-time or more lasting mark on inflation. Powell said it is still unclear how much of the bill would fall on the shoulders of consumers, but he expects to learn more about tariffs

Greek tourism student Katerina quit within a month of starting work at a five-star hotel in Halkidiki, one of the country’s top destinations, because she said conditions were so dire. Beyond the bad pay, the 22-year-old said that her working and living conditions were “miserable and unacceptable.” Millions holiday in Greece every year, but its vital tourism industry is finding it harder and harder to recruit Greeks to look after them. “I was asked to work in any department of the hotel where there was a need, from service to cleaning,” said Katerina, a tourism and marketing student, who would

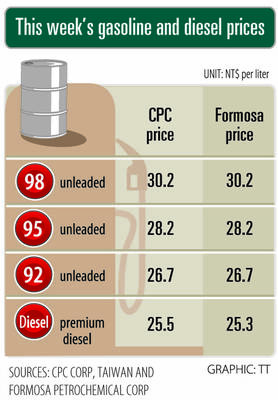

i Gasoline and diesel prices at fuel stations are this week to rise NT$0.1 per liter, as tensions in the Middle East pushed crude oil prices higher last week, CPC Corp, Taiwan (台灣中油) and Formosa Petrochemical Corp (台塑石化) said yesterday. International crude oil prices last week rose for the third consecutive week due to an escalating conflict between Israel and Iran, as the market is concerned that the situation in the Middle East might affect crude oil supply, CPC and Formosa said in separate statements. Front-month Brent crude oil futures — the international oil benchmark — rose 3.75 percent to settle at US$77.01