It is a cheese maker’s take on David and Goliath. Camembert, the village that gave its name to France’s most famous — and imitated — cheese, has only one remaining traditional fromagerie still making the speciality.

And it is holding its own against big industry.

As they tend cows and ladle curdled raw milk into low, wooden cylindrical molds, the Durand family and their employees do not look like militants in a Gallic culinary battle against globalization.

Photo: AFP

However, they are on the front line in this Normandy locality, population 200, on a picturesque hillside where Camembert was first created during the French Revolution.

Dairy producers “are really in dire straits,” said Nicolas Durand, 43, owner of the Heronniere farm in the northwestern French region where Europe’s biggest dairy group, Lactalis, has bought out numerous farms like his.

For a small operation, the “only way to survive is through direct distribution,” he said.

Photo: AFP

Durand’s family acquired the farm in 1961 and has produced Camembert since 1987.

Today his seven employees turn 90 percent of the milk from his 90 cows into 700 to 800 cheeses a day, up from 600 in the year 2000.

Durand sells the minuscule remainder of his output to Agrial, one of France’s top agricultural cooperatives and food processors.

Photo: AFP

Dairy production is a hot-button issue in France. Only last month, the French Ministry of Agriculture had to step in to mediate between Lactalis and farmers angry over what they say are unsustainably low milk prices.

Lactalis today is France’s biggest maker of Camembert, mass producing it for sale in supermarkets at home and abroad under labels like the ubiquitous “President” brand.

However, ask anyone at a Heronniere farm how a “Durand” differs from a factory-produced Camembert and they will laugh, saying even the question is an “insult.”

Photo: AFP

Real Normandy Camembert — a soft-cheese staple on France’s post-dinner cheese plates — finally won the coveted Appellation d’Origine Protegee (AOP, Protected Designation of Origin) only 33 years ago. The label ensures that a product’s origin and fabrication is within a strict geographical area and adheres to traditional methods and craftsmanship.

Local pride is such that a stone monument in honour of Marie Harel — who invented the creamy cheese in 1791 with, as legend has it, the help of a priest — stands in Vimoutiers, the nearby village where she died.

Camembert itself has a museum recounting the history of its speciality, a symbol of the “French way of life.”

Yet half the museum is rented by Lactalis, whose industrial Camemberts tend to be made with pasteurized — not raw — milk.

Moreover, since it is not necessarily from Normandy and is ripened quickly, it cannot bear the “AOP Camembert de Normandie” label.

Durand said that his cheese is not only AOP, it is also fermier, or entirely made on one farm — a mark of distinction in a France struggling to defend terroir, an almost untranslatable notion evoking the goodness of a particular patch of countryside.

“It’s made with milk from our cows and not from a mixture of milk from different farms. That is important for the taste,” Durand said.

“Durand’s flavor stays with you” and it has a stronger, richer scent, one cheese seller from the Normandy port of Caen said.

While an industrial version costs a couple of euros in the supermarket, a Durand Camembert is costlier, fetching 4.40 euros (about US$5) on the farm and 5.60 euros at the Caen merchant’s store.

However, the scene at Durand’s farm looks like just like the cheese making portrayed in the aging black-and-white celluloid film at the museum.

The milk preparation is set in molds to drain for half a day in rooms heated to 32°C.

Because modern sanitary standards require farmers to sterilize the cows’ teats — removing both good and bad bacteria — lactic acids must be added to aid coagulation.

The forms are then taken to the haloirs or drying rooms, and kept at between 12°C and 17°C. Salt is added as well as penicillin, which helps to form Camembert’s characteristic bloomy white rind.

This part takes two weeks, after which the cheese is left again to mature properly. While Durand’s supply is necessarily limited, demand is strong and the farm attracts about 10,000 visitors a year.

He is working with partners to develop his marketing strategy and to ramp up tourist interest even more.

The cheese maker says he brings in about 2,000 euros a month, of which he must pay off 500 euros in loans until 2018.

He also needs to replace his brother and sister-in-law, who left the farm to open a cheese store at Granville on the Normandy coast in July.

Numerous candidates have shown interest, including some from as far away as China and Russia — but Durand said one thing he will not be doing is selling up, to Lactalis or anyone else.

NOT JUSTIFIED: The bank’s governor said there would only be a rate cut if inflation falls below 1.5% and economic conditions deteriorate, which have not been detected The central bank yesterday kept its key interest rates unchanged for a fifth consecutive quarter, aligning with market expectations, while slightly lowering its inflation outlook amid signs of cooling price pressures. The move came after the US Federal Reserve held rates steady overnight, despite pressure from US President Donald Trump to cut borrowing costs. Central bank board members unanimously voted to maintain the discount rate at 2 percent, the secured loan rate at 2.375 percent and the overnight lending rate at 4.25 percent. “We consider the policy decision appropriate, although it suggests tightening leaning after factoring in slackening inflation and stable GDP growth,”

DIVIDED VIEWS: Although the Fed agreed on holding rates steady, some officials see no rate cuts for this year, while 10 policymakers foresee two or more cuts There are a lot of unknowns about the outlook for the economy and interest rates, but US Federal Reserve Chair Jerome Powell signaled at least one thing seems certain: Higher prices are coming. Fed policymakers voted unanimously to hold interest rates steady at a range of 4.25 percent to 4.50 percent for a fourth straight meeting on Wednesday, as they await clarity on whether tariffs would leave a one-time or more lasting mark on inflation. Powell said it is still unclear how much of the bill would fall on the shoulders of consumers, but he expects to learn more about tariffs

Greek tourism student Katerina quit within a month of starting work at a five-star hotel in Halkidiki, one of the country’s top destinations, because she said conditions were so dire. Beyond the bad pay, the 22-year-old said that her working and living conditions were “miserable and unacceptable.” Millions holiday in Greece every year, but its vital tourism industry is finding it harder and harder to recruit Greeks to look after them. “I was asked to work in any department of the hotel where there was a need, from service to cleaning,” said Katerina, a tourism and marketing student, who would

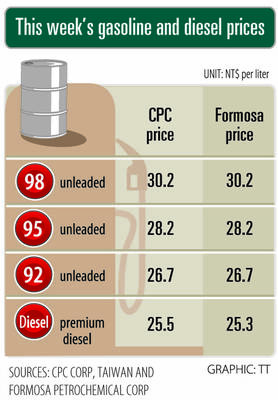

i Gasoline and diesel prices at fuel stations are this week to rise NT$0.1 per liter, as tensions in the Middle East pushed crude oil prices higher last week, CPC Corp, Taiwan (台灣中油) and Formosa Petrochemical Corp (台塑石化) said yesterday. International crude oil prices last week rose for the third consecutive week due to an escalating conflict between Israel and Iran, as the market is concerned that the situation in the Middle East might affect crude oil supply, CPC and Formosa said in separate statements. Front-month Brent crude oil futures — the international oil benchmark — rose 3.75 percent to settle at US$77.01