One in six clothing factories used by Wal-Mart Stores, Inc in Bangladesh failed to meet basic standards of structural, fire or electrical safety, the US retailer has found.

Independent inspections for the company found that 32 of its 200 factories required urgent work to fix serious failings, including one factory that was so unsafe it had to be shut down and another with an illegal eighth floor containing the staff canteen.

Most of those factories have since carried out remedial work, but production is still temporarily halted at two factories, which have failed to make the improvements required for basic safety since the inspections started in May.

The inspections were carried out after the Rana Plaza disaster in April, when more than 1,100 workers died and many more were injured after a factory collapsed.

The problems emerged as Wal-Mart published a list of 75 of the 200 factories that had been inspected and rated on electrical and building safety, from A, which would be a model factory, to D, the worst level.

The paperwork did not give details of the problems at each factory, but Jay Jorgensen, the company’s global compliance officer, said the worst problems included the factory with an additional floor and another with an extra building that it did not have paperwork for.

Walmart had promised to publish a list of the factories it had inspected in June, but Jorgensen said the process had been delayed by civil unrest and difficulties in sourcing sufficient new materials, such as fire doors.

Jorgensen said Wal-Mart had published the list to help other companies sourcing in the country, including the 100-plus signatories to an international factory improvement deal, the accord on fire and building safety in Bangladesh, which Wal-Mart has refused to sign up to.

DIVIDED VIEWS: Although the Fed agreed on holding rates steady, some officials see no rate cuts for this year, while 10 policymakers foresee two or more cuts There are a lot of unknowns about the outlook for the economy and interest rates, but US Federal Reserve Chair Jerome Powell signaled at least one thing seems certain: Higher prices are coming. Fed policymakers voted unanimously to hold interest rates steady at a range of 4.25 percent to 4.50 percent for a fourth straight meeting on Wednesday, as they await clarity on whether tariffs would leave a one-time or more lasting mark on inflation. Powell said it is still unclear how much of the bill would fall on the shoulders of consumers, but he expects to learn more about tariffs

Meta Platforms Inc offered US$100 million bonuses to OpenAI employees in an unsuccessful bid to poach the ChatGPT maker’s talent and strengthen its own generative artificial intelligence (AI) teams, OpenAI CEO Sam Altman has said. Facebook’s parent company — a competitor of OpenAI — also offered “giant” annual salaries exceeding US$100 million to OpenAI staffers, Altman said in an interview on the Uncapped with Jack Altman podcast released on Tuesday. “It is crazy,” Sam Altman told his brother Jack in the interview. “I’m really happy that at least so far none of our best people have decided to take them

PLANS: MSI is also planning to upgrade its service center in the Netherlands Micro-Star International Co (MSI, 微星) yesterday said it plans to set up a server assembly line at its Poland service center this year at the earliest. The computer and peripherals manufacturer expects that the new server assembly line would shorten transportation times in shipments to European countries, a company spokesperson told the Taipei Times by telephone. MSI manufactures motherboards, graphics cards, notebook computers, servers, optical storage devices and communication devices. The company operates plants in Taiwan and China, and runs a global network of service centers. The company is also considering upgrading its service center in the Netherlands into a

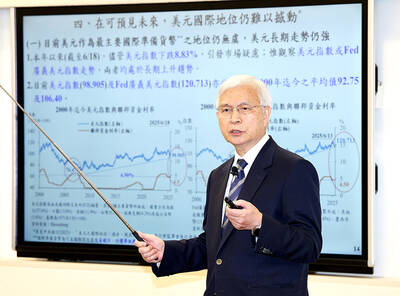

NOT JUSTIFIED: The bank’s governor said there would only be a rate cut if inflation falls below 1.5% and economic conditions deteriorate, which have not been detected The central bank yesterday kept its key interest rates unchanged for a fifth consecutive quarter, aligning with market expectations, while slightly lowering its inflation outlook amid signs of cooling price pressures. The move came after the US Federal Reserve held rates steady overnight, despite pressure from US President Donald Trump to cut borrowing costs. Central bank board members unanimously voted to maintain the discount rate at 2 percent, the secured loan rate at 2.375 percent and the overnight lending rate at 4.25 percent. “We consider the policy decision appropriate, although it suggests tightening leaning after factoring in slackening inflation and stable GDP growth,”