Procter & Gamble (P&G) executives say it was striking the first time they witnessed a man shave while sitting barefoot on the floor in a tiny hut in India.

He had no electricity, no running water and no mirror.

The 20 US-based executives observed the man in 2008 during one of 300 visits they made to homes in rural India. The goal? To gain insights they could use to develop a new razor for India.

“That, for me, was a big ‘a-ha,’” said Alberto Carvalho, vice president, global Gillette, a unit of P&G. “I had never seen people shaving like that.”

The visits kicked off the 18 months it took to develop Gillette Guard, a low-cost razor designed for India and other emerging markets. Introduced three years ago, Guard quickly gained market share and today represents two out of every three razors sold in India. The story of how Guard came to be illustrates the balance companies must strike when creating products for emerging markets: It is not as simple as slapping a foreign label on a US product.

To successfully sell products overseas, particularly in developing markets, companies must tweak them so they are relevant to the people who live there. And often, that means rethinking everything from the product’s design to its cost. More companies will have to consider this balancing act as they increasingly move into emerging markets such as India, China and Brazil to offset slower growth in developed regions such as the US.

For its part, P&G has doubled the percentage of its roughly US$20 billion in annual revenue coming from emerging markets since 2000 to about 40 percent. Ali Dibadj, a Bernstein analyst who follows P&G, said the Guard razor, which has been used by more than 50 million men in India, serves as a roadmap for companies seeking to court emerging markets.

“It made P&G realize how much investment it really takes to be successful in India,” he said. “That’s the art of emerging markets.”

India long has been an attractive country for US companies looking for growth. It has 1.24 billion people and GDP growth of 3.2 percent last year, according to the World Bank, compared with 2.2 percent in the US.

Still, India’s widespread poverty presents challenges for companies used to customers with more disposable income. India’s per capita income is just about US$124 a month, compared with US$4,154 in the US, World Bank data show.

Gillette has sold razors in India for more than a decade. The company had 37.3 percent market share in 2007, selling its high end Mach3 razor, which costs about US$2.75, and a stripped down Vector two-bladed razor on the lower end, which goes for about US$0.72.

However, Gillette wanted more of the market. To do that, P&G executives would have to attract the nearly 500 million Indians who use double-edged razors, an old fashioned T-shaped razor that has no protective piece of plastic that goes between the blade and the skin when shaving. This razor, which makes skin cuts more likely, costs just a few pennies per blade.

However, Carvalho, who spearheaded Gillette’s effort to grow market share in India, did not want to rush into designing a product. Gillette had stumbled once before with its early version of the Vector in 2002. The version of that razor had a plastic push bar that slid down to unclog the razor. The bar was added because Indian men have thicker hair and a higher hair density than their American counterparts. Adding to that, they often shave less frequently than American men, so they wind up shaving longer beards.

Gillette, which is based in Boston, wanted to test the product among Indian consumers before launching it, but instead of making the costly trip abroad, they had Indian students at nearby Massachusetts Institute of Technology (MIT) test the razor.

“They all came back and said: ‘Wow that’s a big improvement,’” Carvalho recalled.

However, when Gillette launched the razor in India, the reaction was different. Executives were baffled about why the razor flopped until they traveled to India and observed men using a cup of water to shave. All the MIT students had running water. Without that, the razor stayed clogged.

“That’s another ‘a-ha’ moment,” Carvalho said. “That taught us the importance that you really need to go where your consumers are, not just to talk to them, but observe and spend time with them to gather the key insight.”

P&G acquired Gillette in 2005 and the next several years were spent integrating the companies. In 2008, the focus on India returned when Carvalho decided to bring 20 people, ranging from engineers to developers, from Gillette’s US headquarters to India for three weeks.

They spent 3,000 hours with more than 1,000 consumers at their homes, in stores and in small group discussions. They observed people’s routines throughout the day, sometimes staying late into the evening. They also hosted small group discussions.

“We asked them what their aspirations were and why they wanted to shave, and how often,” Carvahlo said.

They learned that families often live in huts without electricity and share a bathroom with other huts. So men shave sitting on their floors with a bowl of water, often without a mirror, in the dark morning hours. As a result, shaving could take up to half an hour, compared with the five to seven minutes it takes to shave in US households. And Indian men strain to not cut themselves.

The takeaway: In the US, razor makers spent decades on marketing centered on a close shave, adding blade after blade to achieve a smoother cheek, but men in India are more concerned about not cutting themselves.

“I worked in this category for 23 years and I never realized with those insights that’s how they think about the product,” said Eric Liu, Gillette’s director of research and development, global shave care.

With that knowledge, the Gillette team started making a new razor for the Indian market. In nine months, P&G developed five prototypes.

The company declined to give specifics on each prototype for competitive reasons, but it tested things like handle designs, how well the blade cuts hair and how easy the razor is to rinse.

The resulting Guard razor has one blade, to put the emphasis on safety rather than closeness, compared with two to five blades found on US razors.

One insight from filming shavers was that Indians grip the razors in many different ways, so the handle is textured to allow for easy gripping. There is also a hole at the handle’s base to make it easier to hang up, and a small comb by the blade since Indians hair growth tends to be thicker.

Next, the company had to figure out how to produce the razor at the right price.

“We had to say: ‘How do we do this at ruthless cost?’” Carvalho said.

P&G scrutinized the smallest details. It cut the number of components in the razor down to 4 compared with 25 needed for Mach3, Gillette’s three-blade razor. They even made the razor’s handle hollow so it would be lighter and cheaper to make.

“I can remember talking about changes to this product that were worth a thousandth, or two thousandths of a cent,” said Jim Keighley, the company’s associate director for product engineering.

The result? The Guard costs about one third of what it costs to make the Vector, Gilllette’s low-price Indian razor before Guard. Gillette sells the Guard for 15 rupees, or US$0.34, and each razor blade is 5 rupees.

The company’s strategy seems to have worked. P&G says with 9 percent market share, Guard has grown share faster than any other P&G brand in India. And Gillette’s market share for razors and blades in India has grown to 49.1 percent, according to Euromonitor. That is up from 37.3 in 2007.

SETBACK: Apple’s India iPhone push has been disrupted after Foxconn recalled hundreds of Chinese engineers, amid Beijing’s attempts to curb tech transfers Apple Inc assembly partner Hon Hai Precision Industry Co (鴻海精密), also known internationally as Foxconn Technology Group (富士康科技集團), has recalled about 300 Chinese engineers from a factory in India, the latest setback for the iPhone maker’s push to rapidly expand in the country. The extraction of Chinese workers from the factory of Yuzhan Technology (India) Private Ltd, a Hon Hai component unit, in southern Tamil Nadu state, is the second such move in a few months. The company has started flying in Taiwanese engineers to replace staff leaving, people familiar with the matter said, asking not to be named, as the

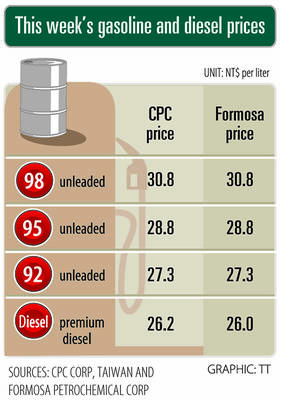

The prices of gasoline and diesel at domestic fuel stations are to rise NT$0.1 and NT$0.4 per liter this week respectively, after international crude oil prices rose last week, CPC Corp, Taiwan (台灣中油) and Formosa Petrochemical Corp (台塑石化) announced yesterday. Effective today, gasoline prices at CPC and Formosa stations are to rise to NT$27.3, NT$28.8 and NT$30.8 per liter for 92, 95 and 98-octane unleaded gasoline respectively, the companies said in separate statements. The price of premium diesel is to rise to NT$26.2 per liter at CPC stations and NT$26 at Formosa pumps, they said. The announcements came after international crude oil prices

SinoPac Financial Holdings Co (永豐金控) is weighing whether to add a life insurance business to its portfolio, but would tread cautiously after completing three acquisitions in quick succession, president Stanley Chu (朱士廷) said yesterday. “We are carefully considering whether life insurance should play a role in SinoPac’s business map,” Chu told reporters ahead of an earnings conference. “Our priority is to ensure the success of the deals we have already made, even though we are tracking some possible targets.” Local media have reported that Mercuries Life Insurance Co (三商美邦人壽), which is seeking buyers amid financial strains, has invited three financial

CAUTION: Right now, artificial intelligence runs on faith, not productivity and eventually, the risk of a bubble will emerge,’ TIER economist Gordon Sun said Taiwanese manufacturers turned more optimistic last month, ending a five-month streak of declining sentiment as concerns over US tariffs, currency volatility and China’s overcapacity began to ease, the Taiwan Institute of Economic Research (TIER) said yesterday. The manufacturing business confidence index rose 1.17 points from June to 86.8, its first rebound since February. TIER economist Gordon Sun (孫明德) attributed the uptick to fading trade uncertainties, a steadier New Taiwan dollar and reduced competitive pressure from Chinese producers. Taiwan’s semiconductor industry is unlikely to face significant damage from Washington’s ongoing probe into semiconductors, given the US’ reliance on Taiwanese chips to power artificial