Fourteen years after Lexus luxury cars went on sale in the US, the Toyota Motor Co opened the first Lexus assembly line in North America on Friday.

Loud music and fake smoke filled the air as an audience packed with Canadian dignitaries and Japanese executives applauded the first car to roll out of the factory, a silver RX 330 sport utility vehicle. The hubbub made it hard to hear people talking, but it did not obscure the bigger message: Foreign rivals are determinedly pursuing the last redoubt of profitability for American carmakers, SUVs and pickup trucks.

Toyota's decision to start making Lexus models, its luxury line, outside Japan for the first time signals the start of a second wave of foreign luxury vehicle production in North America, nearly a decade after the German automaker BMW started the phenomenon by opening a plant in Greer, South Carolina.

In January, Nissan, whose Infiniti brand made its debut the same year as Lexus, will begin building a new SUV at the company's plant in Canton, Mississippi, which just opened. Mercedes-Benz, meanwhile, is spending US$600 million to double the size of its factory in Vance, Alabama, where it has built the M-Class SUV since 1997.

And Honda is developing a sporty pickup truck that is expected to be shared with its Acura luxury brand. It plans to build the truck at either its plant in Alliston, Ontario, where it assembles the Acura MDX sport utility, or at its factory in Lincoln, Alabama.

Foreign automobile manufacturers have controlled the luxury vehicle market in the US since 1986; the three leading sellers are Lexus, BMW and Mercedes. Though a determined resurgence is under way at Cadillac, industry analysts said they thought that companies based in Japan and Europe would only continue their upward sales march.

"We've had a fundamental shift" by upscale American consumers to foreign luxury vehicles, said Karl Brauer, editor in chief of Edmu-nds.com, which offers car-buying advice to consumers.

This is particularly bad news for American carmakers because luxury vehicles -- including well-appointed SUVs and pickups -- are one of the few market segments in which sales are growing and profits are promising.

As sales in North America grow, European and Japanese companies have found it useful to open factories here. Producing cars locally lets them respond more quickly to consumer tastes, provides some protection from fluctuating currency exchange rates and helps defuse consumers' concerns about putting Americans out of work by buying cars made overseas.

Spending hundreds of millions of dollars to build factories in North America has also demonstrated the foreign carmakers' long-term commitment to increasing their sales here.

To their surprise, these companies have discovered that the quality of the vehicles built in American and Canadian plants equals, and in some cases exceeds, that of vehicles built overseas, according to annual surveys by Consumer Reports magazine and J.D. Power & Associates.

That quality is evident in dealer showrooms. After a brisk August, Lexus is virtually sold out of cars and trucks. There is only a five-day supply of the RX 330, for example, the best-selling vehicle in the Lexus lineup. Denny Clements, Lexus' general manager, said his company could easily sell more than 300,000 vehicles this year, smashing its sales record of 234,000, if it had enough cars and trucks to meet the demand.

Sales of luxury SUVs are leading the way. Every foreign luxury manufacturer with a plant in North America builds at least one sport utility: Next year, the expanded Mercedes-Benz plant will add a second model alongside the M-Class. It will be called the GST, for Grand Sport Tourer.

Producing SUVs here means that factories in Europe and Japan can concentrate on producing luxury cars, which sell better overseas than light trucks.

"The American market is very truck happy," Brauer said, adding, "The first truck-type vehicle that BMW built was an X5 in South Carolina that had nothing to do with Europe at all."

Greek tourism student Katerina quit within a month of starting work at a five-star hotel in Halkidiki, one of the country’s top destinations, because she said conditions were so dire. Beyond the bad pay, the 22-year-old said that her working and living conditions were “miserable and unacceptable.” Millions holiday in Greece every year, but its vital tourism industry is finding it harder and harder to recruit Greeks to look after them. “I was asked to work in any department of the hotel where there was a need, from service to cleaning,” said Katerina, a tourism and marketing student, who would

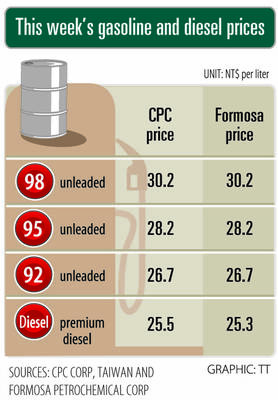

i Gasoline and diesel prices at fuel stations are this week to rise NT$0.1 per liter, as tensions in the Middle East pushed crude oil prices higher last week, CPC Corp, Taiwan (台灣中油) and Formosa Petrochemical Corp (台塑石化) said yesterday. International crude oil prices last week rose for the third consecutive week due to an escalating conflict between Israel and Iran, as the market is concerned that the situation in the Middle East might affect crude oil supply, CPC and Formosa said in separate statements. Front-month Brent crude oil futures — the international oil benchmark — rose 3.75 percent to settle at US$77.01

Merida Industry Co (美利達) has seen signs of recovery in the US and European markets this year, as customers are gradually depleting their inventories, the bicycle maker told shareholders yesterday. Given robust growth in new orders at its Taiwanese factory, coupled with its subsidiaries’ improving performance, Merida said it remains confident about the bicycle market’s prospects and expects steady growth in its core business this year. CAUTION ON CHINA However, the company must handle the Chinese market with great caution, as sales of road bikes there have declined significantly, affecting its revenue and profitability, Merida said in a statement, adding that it would

UNCERTAINTIES: The world’s biggest chip packager and tester is closely monitoring the US’ tariff policy before making any capacity adjustments, a company official said ASE Technology Holding Inc (日月光投控), the world’s biggest chip packager and tester, yesterday said it is cautiously evaluating new advanced packaging capacity expansion in the US in response to customers’ requests amid uncertainties about the US’ tariff policy. Compared with its semiconductor peers, ASE has been relatively prudent about building new capacity in the US. However, the company is adjusting its global manufacturing footprint expansion after US President Donald Trump announced “reciprocal” tariffs in April, and new import duties targeting semiconductors and other items that are vital to national security. ASE subsidiary Siliconware Precision Industries Co (SPIL, 矽品精密) is participating in Nvidia