A team of researchers yesterday said that they have used new materials to separate hydrogen from water, which they said could improve light conversion and advance the application of the clean energy source.

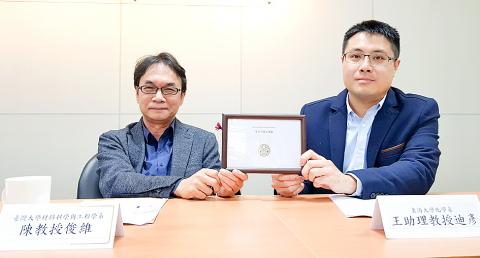

Hydrogen is a promising source of clean energy with no carbon emissions and the Japanese government is promoting it to power many facilities for the Tokyo Olympics this summer, National Taiwan University material science professor Chen Chun-wei (陳俊維), who led the research team, told a news conference at Ministry of Science and Technology in Taipei.

However, the production of hydrogen is costly and requires a considerable amount of electricity, and using solar energy to reduce costs is a critical research topic, he said.

Photo: Chien Hui-ju, Taipei Times

While silicon is a commercial photo-electrochemical material, silicon solar panels reflect and waste up to 40 percent of sunlight and cannot withstand the corrosion caused by electrolytic solution, Chen said.

The team has over the past decade been conducting research under the ministry’s Taiwan Consortium of Emergent Crystalline Materials program.

About three years ago, it found a method to improve the efficiency of silicon by applying a thin graphene layer, Chen said.

The graphene layer is made up of a single layer of atoms and is only 0.34 nanometers thick — one-100,000th of a human hair — so that it would not reduce light penetration, while it exhibits great optoelectronic properties and provides superior corrosion protection, he said.

The most challenging part was evenly distributing the graphene layer on silicon panels, as the traditional way of coating using polymethylmethacrylate cannot flexibly attach the layer on a rough surface, Chen said.

To overcome the problem, the team developed a novel method using ethylene-vinyl acetate, a soft polymer, for the coating, improving the light absorption of silicon panels by nearly 20 percent, he said.

National Taiwan University of Science and Technology chemical engineering professor Hwang Bing-joe (黃炳照) and Tunghai University assistant professor of chemistry Wang Di-yan (王迪彥) were also part of the team.

They detailed their findings in a paper published in the journal Advanced Energy Materials in August last year, with the paper featured on the back cover of the issue.

While they still need to introduce additional electricity, as well as platinum as a catalyst, to assist in the photo-electrochemical water splitting process to produce hydrogen, their ultimate goal is to do so without using electricity, Wang said.

In view of large-scale industrial application, operators would have to produce a large amount of graphene and opt for a more cost-efficient catalyst, he added.

A small number of Taiwanese this year lost their citizenship rights after traveling in China and obtaining a one-time Chinese passport to cross the border into Russia, a source said today. The people signed up through Chinese travel agencies for tours of neighboring Russia with companies claiming they could obtain Russian visas and fast-track border clearance, the source said on condition of anonymity. The travelers were actually issued one-time-use Chinese passports, they said. Taiwanese are prohibited from holding a Chinese passport or household registration. If found to have a Chinese ID, they may lose their resident status under Article 9-1

Taiwanese were praised for their composure after a video filmed by Taiwanese tourists capturing the moment a magnitude 7.5 earthquake struck Japan’s Aomori Prefecture went viral on social media. The video shows a hotel room shaking violently amid Monday’s quake, with objects falling to the ground. Two Taiwanese began filming with their mobile phones, while two others held the sides of a TV to prevent it from falling. When the shaking stopped, the pair calmly took down the TV and laid it flat on a tatami mat, the video shows. The video also captured the group talking about the safety of their companions bathing

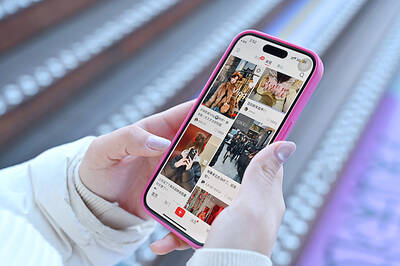

PROBLEMATIC APP: Citing more than 1,000 fraud cases, the government is taking the app down for a year, but opposition voices are calling it censorship Chinese Nationalist Party (KMT) Chairwoman Cheng Li-wun (鄭麗文) yesterday decried a government plan to suspend access to Chinese social media platform Xiaohongshu (小紅書) for one year as censorship, while the Presidential Office backed the plan. The Ministry of the Interior on Thursday cited security risks and accusations that the Instagram-like app, known as Rednote in English, had figured in more than 1,700 fraud cases since last year. The company, which has about 3 million users in Taiwan, has not yet responded to requests for comment. “Many people online are already asking ‘How to climb over the firewall to access Xiaohongshu,’” Cheng posted on

A classified Pentagon-produced, multiyear assessment — the Overmatch brief — highlighted unreported Chinese capabilities to destroy US military assets and identified US supply chain choke points, painting a disturbing picture of waning US military might, a New York Times editorial published on Monday said. US Secretary of Defense Pete Hegseth’s comments in November last year that “we lose every time” in Pentagon-conducted war games pitting the US against China further highlighted the uncertainty about the US’ capability to intervene in the event of a Chinese invasion of Taiwan. “It shows the Pentagon’s overreliance on expensive, vulnerable weapons as adversaries field cheap, technologically