A handful of noteworthy books have been published in recent years that attempt to weigh the impact of the world’s intoxication with “made in China” products. Financial Times reporter Alexandra Harney’s The China Price, an expose of the human cost associated with China’s competitive advantage, readily comes to mind. More recently, Paul Midler, who for years worked as a consultant and go-between for American importers who descended upon China like sailors to a siren, explores another aspect of the ambiguous relationship — the corporate machinations.

This isn’t to say that Midler’s book, Poorly Made in China, doesn’t have a human element to it. Quite the contrary. Its pages are filled with individuals who truly come to life as they make their first excited steps in China, are courted, get deceived, become disillusioned and, quite often, resignedly do whatever it takes to keep their businesses running. The entire book is human theater, a well-paced and entertaining tale of egos hurt and ridiculous retribution, such as when the author, who perhaps had dug a little too deep, suddenly found it impossible to get a ride back home from the factory.

Despite the many cunning factory chiefs and wide-eyed foreign importers who form the dramatis personae in this book, Poorly Made in China has surprisingly little to say about the fate of the Chinese workers who have made it possible for China’s giant wheel to start turning. We witness a brief, and ultimately pointless, public demonstration, and a handful of workers make the odd appearance, but the focus clearly isn’t on them. Rather, what Midler exposes is the mechanism by which Chinese manufacturers have succeeded in drawing in foreign importers and, equally important, how they made it almost impossible to leave.

In this game, China has many elements playing in its favor. It has a mythical power of attraction, it knows how to unfurl the red carpet to make foreign investors feel like a million dollars, and, a major advantage over its would-be competitors, such as India and Vietnam, it has the infrastructure and adaptability to make manufacturing on a massive scale possible.

Midler’s case studies show us the anatomy of the rise and fall of importers’ relationships with Chinese manufacturers. In the early courting phase, Chinese manufacturers are the epitome of deference and show an incomprehensible (to foreigners) willingness to produce at almost zero-profit, which for obvious reasons proves irresistible to prospective importers. As the relationship matures and the importer becomes over-reliant on the manufacturer, however, small things start happening. Corners are cut. Ingredients are changed without notice. Bottles aren’t properly filled, or the plastic becomes of lesser quality. Shampoo turns into Jell-O.

Guerrilla-like, the manufacturer sallies forth and retreats, making a profit by finding ways to cut on manufacturing costs, oftentimes at the risk of compromising the health of customers (at one point, Midler writes that he’d seen so much to worry about in the skin care products he was monitoring that he stopped using body wash and shampoo altogether). Worryingly, we learn the testing that would ensure product safety is often too costly and is passed on like a hot potato from the manufacturer to the importer, the retailer and, ultimately, to the consumer. On many occasions, the testing is simply not done. Equally disturbing is the fact that manufacturers often keep the list of ingredients secret, even from their clients.

Though Chinese manufacturers that succeed in bringing in foreign investment are celebrated and will sometimes score political points with Beijing, their involvement with importers also presents other lucrative, if not entirely kosher, opportunities. A recurrent one is counterfeiting: stealing an idea, replicating it — the Chinese are past masters at this art — and repackaging it while selling it for a fraction of the price charged for the real product. Another strategy, we learn, is to produce more than what is ordered by an importer and then to approach the retailer directly and offer the same item for less than the importer would ordinarily charge — in other words, bypassing the middleman.

Midler’s worries about the possibility of collusion among Chinese manufacturers and its impact on prices and quality are well founded. Over the years, Chinese manufacturers have formed tightly knit networks of sub-suppliers involving producers of raw materials all the way to makers of end products. Most company chiefs know each other, are part of the same family or went to the same business schools. Consequently, disillusioned importers who, after being burned once too often, threaten to shift manufacturing to the competition have a major handicap, while leaving the country altogether is out of the question, given the months that it takes to consolidate a business relationship. The possibility of collusion, and the weak government regulations and corruption that facilitate the process, also put foreign manufacturers operating in China — such as Taiwanese — at a clear disadvantage, as they are not part of that network and will therefore be charged more for raw materials and components.

Relationships are at their best when operations are small and at their inception. Once a manufacturer has gained what it sought and mired its client in Chinese quicksand, the quality of its product and its willingness to clean up its act drops, often dramatically. Despite this, as Midler shows us, importers will often show unnatural patience and a willingness to look the other way. For many, they’ve gotten in so deep that pulling out would mean corporate suicide. In fact, the book has its share of promising partnerships that, in the end, brought American companies asunder. So the silly dance continues, and consumers are the real losers. Toys, pet food, baby cribs, toothpaste — the potential health hazards are the cost of our frenzied venture into China when neither we, nor the awakening giant, were ready for, or understood, the implications of what we were doing when we opened the gate and jumped in.

Poorly Made in China is an important, timely and thoroughly entertaining read that, inter alia, provides a warning about our future engagements with China in other fields, where we can expect it to act with equal selfishness and to treat its interlocutors as mere means to an end. The cost of that will likely make bad cheap shampoo but a trifle.

Towering high above Taiwan’s capital city at 508 meters, Taipei 101 dominates the skyline. The earthquake-proof skyscraper of steel and glass has captured the imagination of professional rock climber Alex Honnold for more than a decade. Tomorrow morning, he will climb it in his signature free solo style — without ropes or protective equipment. And Netflix will broadcast it — live. The event’s announcement has drawn both excitement and trepidation, as well as some concerns over the ethical implications of attempting such a high-risk endeavor on live broadcast. Many have questioned Honnold’s desire to continues his free-solo climbs now that he’s a

As Taiwan’s second most populous city, Taichung looms large in the electoral map. Taiwanese political commentators describe it — along with neighboring Changhua County — as Taiwan’s “swing states” (搖擺州), which is a curious direct borrowing from American election terminology. In the early post-Martial Law era, Taichung was referred to as a “desert of democracy” because while the Democratic Progressive Party (DPP) was winning elections in the north and south, Taichung remained staunchly loyal to the Chinese Nationalist Party (KMT). That changed over time, but in both Changhua and Taichung, the DPP still suffers from a “one-term curse,” with the

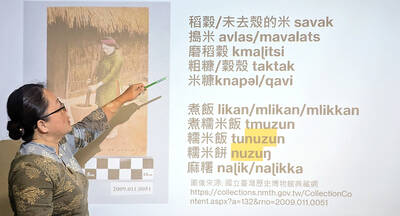

Jan. 26 to Feb. 1 Nearly 90 years after it was last recorded, the Basay language was taught in a classroom for the first time in September last year. Over the following three months, students learned its sounds along with the customs and folktales of the Ketagalan people, who once spoke it across northern Taiwan. Although each Ketagalan settlement had its own language, Basay functioned as a common trade language. By the late 19th century, it had largely fallen out of daily use as speakers shifted to Hoklo (commonly known as Taiwanese), surviving only in fragments remembered by the elderly. In

Lines between cop and criminal get murky in Joe Carnahan’s The Rip, a crime thriller set across one foggy Miami night, starring Matt Damon and Ben Affleck. Damon and Affleck, of course, are so closely associated with Boston — most recently they produced the 2024 heist movie The Instigators there — that a detour to South Florida puts them, a little awkwardly, in an entirely different movie landscape. This is Miami Vice territory or Elmore Leonard Land, not Southie or The Town. In The Rip, they play Miami narcotics officers who come upon a cartel stash house that Lt. Dane Dumars (Damon)