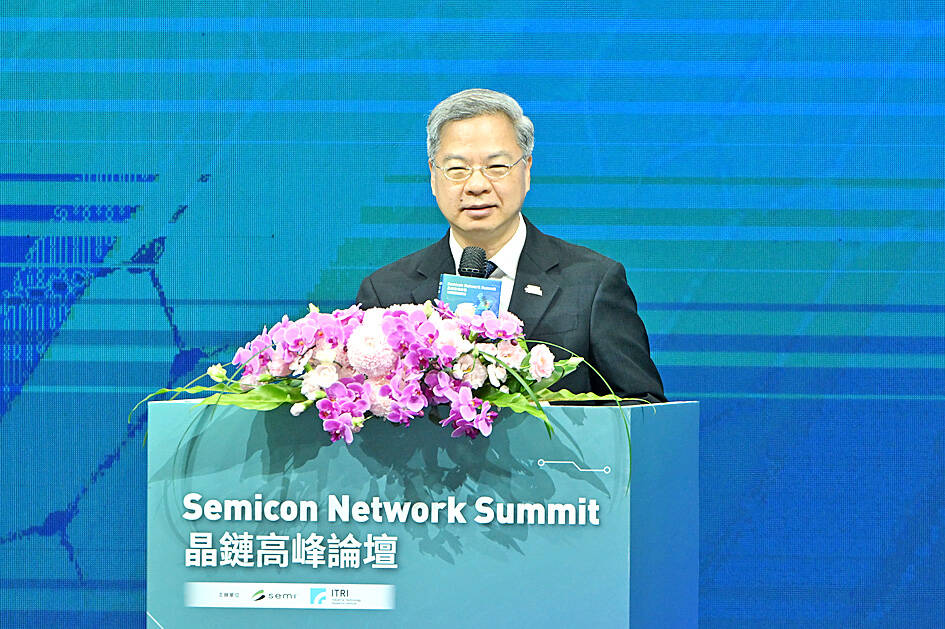

Challenges to the global semiconductor supply chain, including geopolitical tensions, extreme weather, limited access to key materials and unstable demand, have tested the industry’s resilience and capacity for cooperation, Minister of Economic Affairs Kung Ming-hsin (龔明鑫) said yesterday.

To address these challenges, the semiconductor industry should cooperate in three areas: working together as globalization is restructured, co-developing advanced technologies and sharing information through communication platforms, Kung said at a forum in Taipei ahead of the Semicon Taiwan trade show that is scheduled to open today.

The forum featured industry representatives, including SEMI International Board chairman Tien Wu (吳田玉), Merck Group Taiwan managing director John Lee (李俊隆), Applied Materials Inc vice president of engineering Chen Jang-fung (陳正方) and Micron Memory Japan vice president Kota Nosaka.

Photo: Tien Yu-hua, Taipei Times

Amid geopolitical regulatory uncertainty, it is important to consider how multinational corporations can work together to identify the most efficient path forward, Wu said.

Each country and company must be strong, but in a complex environment, simplified solutions are key, Wu said, adding that history shows those who optimize and simplify are more likely to survive.

While Taiwan produces about 90 percent of the world’s artificial intelligence (AI) chips, its share of next-generation silicon photonics remains unclear, but demand for the technology is expected to grow as AI infrastructure expands, Wu said.

The technology requires decade-long planning to realize the industry’s vision, and as the number of transistors per chip continues to grow, power supply and management could emerge as the next bottleneck in developing chip-on-wafer-on-substrate (CoWoS) and 3D integrated circuit packaging, he said.

As the semiconductor industry shifts toward regionalization and localization, it can simplify global operations, strengthen supply chain resilience and reduce international material transport, while also lowering its overall carbon footprint and enhancing customer satisfaction, Lee said.

Meanwhile, Chen said Applied Materials regards Taiwan as having three major advantages: its proximity to customers, strong manufacturing teams and abundant local talent.

Those factors are why that nation should act as a strategic coordinator to balance upstream material supply with downstream testing and packaging, Chen said.

The nation’s semiconductor expertise could also be applied to quantum computing, he said.

Kung said in conclusion that as Taiwan’s industry clusters are highly concentrated, they provide high production efficiency.

The industry should stay rooted in Taiwan while maintaining a global focus, he said, adding that the nation is willing to share its experience with the world.

In Italy’s storied gold-making hubs, jewelers are reworking their designs to trim gold content as they race to blunt the effect of record prices and appeal to shoppers watching their budgets. Gold prices hit a record high on Thursday, surging near US$5,600 an ounce, more than double a year ago as geopolitical concerns and jitters over trade pushed investors toward the safe-haven asset. The rally is putting undue pressure on small artisans as they face mounting demands from customers, including international brands, to produce cheaper items, from signature pieces to wedding rings, according to interviews with four independent jewelers in Italy’s main

Japanese Prime Minister Sanae Takaichi has talked up the benefits of a weaker yen in a campaign speech, adopting a tone at odds with her finance ministry, which has refused to rule out any options to counter excessive foreign exchange volatility. Takaichi later softened her stance, saying she did not have a preference for the yen’s direction. “People say the weak yen is bad right now, but for export industries, it’s a major opportunity,” Takaichi said on Saturday at a rally for Liberal Democratic Party candidate Daishiro Yamagiwa in Kanagawa Prefecture ahead of a snap election on Sunday. “Whether it’s selling food or

CONCERNS: Tech companies investing in AI businesses that purchase their products have raised questions among investors that they are artificially propping up demand Nvidia Corp chief executive officer Jensen Huang (黃仁勳) on Saturday said that the company would be participating in OpenAI’s latest funding round, describing it as potentially “the largest investment we’ve ever made.” “We will invest a great deal of money,” Huang told reporters while visiting Taipei. “I believe in OpenAI. The work that they do is incredible. They’re one of the most consequential companies of our time.” Huang did not say exactly how much Nvidia might contribute, but described the investment as “huge.” “Let Sam announce how much he’s going to raise — it’s for him to decide,” Huang said, referring to OpenAI

The global server market is expected to grow 12.8 percent annually this year, with artificial intelligence (AI) servers projected to account for 16.5 percent, driven by continued investment in AI infrastructure by major cloud service providers (CSPs), market researcher TrendForce Corp (集邦科技) said yesterday. Global AI server shipments this year are expected to increase 28 percent year-on-year to more than 2.7 million units, driven by sustained demand from CSPs and government sovereign cloud projects, TrendForce analyst Frank Kung (龔明德) told the Taipei Times. Demand for GPU-based AI servers, including Nvidia Corp’s GB and Vera Rubin rack systems, is expected to remain high,