Resonac Holdings Corp is ready to spend hundreds of billions of yen on chip acquisitions, as the 84-year-old chemicals giant seeks to boost its role as a pivotal supplier to global giants such as Taiwan Semiconductor Manufacturing Co (TSMC, 台積電) and Samsung Electronics Co.

The Japanese company, which last year outlined a ¥250 billion (US$1.94 billion) blueprint to enhance its chip facilities by 2027, aims to capitalize on a much-needed consolidation of the US$580 billion semiconductor industry, CEO Hidehito Takahashi said.

Resonac, which changed its name from Showa Denko to reflect its changing focus, must find partners to thrive in an increasingly politicized and economically uncertain environment, he said.

Photo: AFP

Takahashi said there are not many attractive acquisition targets right now as the industry is in a state of flux, but Resonac is looking to invest, and one promising country is the US, as its major customers, from Samsung to TSMC, spend billions to build plants there.

The Japanese company remains cautious about spending in China, given Washington’s escalating campaign to curb that country’s semiconductor industry, he said.

“I’m always on the lookout for potential acquisition chances, and I wouldn’t hesitate to spend a hundred billion yen if it merits restructuring our business portfolio,” the 61-year-old executive said.

“When a deal is justified, I will go ahead and throw hundreds of billions of yen at it as there are many financial tools for us to leverage,” he said. “The problem is that no one wants to sell businesses that are growing.”

Demand for chips cratered last year after consumers and businesses turned cautious about spending on everything from servers to smartphones. Washington’s effort to curb Beijing’s ambitions in semiconductors, as well as uncertainty about a potential global recession, have clouded the sector’s prospects.

“Everyone in the industry feels uneasy going it alone,” Takahashi said. “I have no doubt consolidation is ahead for the industry, and the key is forming as many alliances as possible.”

Some could evolve into acquisition talks, he added.

Growing through acquisitions is part of Resonac’s well-established playbook.

Takahashi, a former General Electric Co executive, led one of the Japanese company’s most transformative deals. Resonac paid more than double its market value for the chemicals unit of Hitachi Ltd in 2020, a US$8.8 billion deal that made it a major supplier of a key compound used to polish the surface of silicon wafers.

Resonac leads the market in key semiconductor packaging materials such as copper-clad laminates and photosensitive film, and it aims to increase the proportion of revenue from chip materials to 45 percent of overall sales by 2030 from 31 percent in 2021.

The company is researching next-generation 3D packaging technology, anticipating a potential industry shift that could drive its next phase of growth.

SETBACK: Apple’s India iPhone push has been disrupted after Foxconn recalled hundreds of Chinese engineers, amid Beijing’s attempts to curb tech transfers Apple Inc assembly partner Hon Hai Precision Industry Co (鴻海精密), also known internationally as Foxconn Technology Group (富士康科技集團), has recalled about 300 Chinese engineers from a factory in India, the latest setback for the iPhone maker’s push to rapidly expand in the country. The extraction of Chinese workers from the factory of Yuzhan Technology (India) Private Ltd, a Hon Hai component unit, in southern Tamil Nadu state, is the second such move in a few months. The company has started flying in Taiwanese engineers to replace staff leaving, people familiar with the matter said, asking not to be named, as the

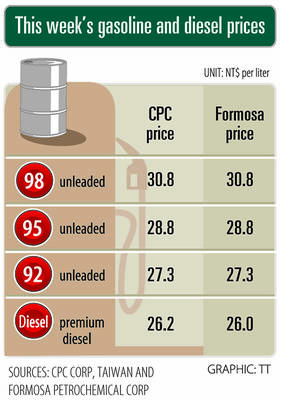

The prices of gasoline and diesel at domestic fuel stations are to rise NT$0.1 and NT$0.4 per liter this week respectively, after international crude oil prices rose last week, CPC Corp, Taiwan (台灣中油) and Formosa Petrochemical Corp (台塑石化) announced yesterday. Effective today, gasoline prices at CPC and Formosa stations are to rise to NT$27.3, NT$28.8 and NT$30.8 per liter for 92, 95 and 98-octane unleaded gasoline respectively, the companies said in separate statements. The price of premium diesel is to rise to NT$26.2 per liter at CPC stations and NT$26 at Formosa pumps, they said. The announcements came after international crude oil prices

A German company is putting used electric vehicle batteries to new use by stacking them into fridge-size units that homes and businesses can use to store their excess solar and wind energy. This week, the company Voltfang — which means “catching volts” — opened its first industrial site in Aachen, Germany, near the Belgian and Dutch borders. With about 100 staff, Voltfang says it is the biggest facility of its kind in Europe in the budding sector of refurbishing lithium-ion batteries. Its CEO David Oudsandji hopes it would help Europe’s biggest economy ween itself off fossil fuels and increasingly rely on climate-friendly renewables. While

SinoPac Financial Holdings Co (永豐金控) is weighing whether to add a life insurance business to its portfolio, but would tread cautiously after completing three acquisitions in quick succession, president Stanley Chu (朱士廷) said yesterday. “We are carefully considering whether life insurance should play a role in SinoPac’s business map,” Chu told reporters ahead of an earnings conference. “Our priority is to ensure the success of the deals we have already made, even though we are tracking some possible targets.” Local media have reported that Mercuries Life Insurance Co (三商美邦人壽), which is seeking buyers amid financial strains, has invited three financial