Flextronics International Ltd has created a system that combines information from social media, emergency warning systems and its own data on product movement to help the electronics contract manufacturer quickly adjust its work flow due to global disruptions.

“We’re dealing with shorter product life cycles, more innovation from more competitors around the world and rising consumption in more emerging markets,” Flextronics chief executive officer Mike McNamara said on Tuesday.

“If we can’t get at real-time information, it’s going to be difficult to run these increasingly complex supply chains,” McNamara said.

Flextronics, like other electronics manufacturers, has been seeking to diversify from building computers and phones into wearables and consumer businesses.

Being able to respond quickly to supply-chain disruptions might give the company and its customers an edge.

Flex Pulse, as the project is known, could let the Singapore-based manufacturer buy disk drives at the first signs that a flood could damage drive factories in Thailand, before prices rise, McNamara said.

Flextronics also could, for example, shift final assembly of products from China to Mexico to avoid the effects of a possible strike at the Port of Long Beach, California.

During a demonstration of the system to US Secretary of Commerce Penny Pritzker at the company’s campus in Milpitas, California, McNamara spoke about the possibility of integrating weather data from the US Department of Commerce.

While the company is a distant No. 2 behind Taiwan-based Hon Hai Precision Industry Co (鴻海精密), Flextronics’ customer base is broader.

Hon Hai generated 50 percent of its US$139 billion in sales for its latest fiscal year from Apple Inc and about 15 percent in total from Dell Inc and Hewlett-Packard Co, according to data compiled by Bloomberg. Flextronics’ largest customer was Lenovo Group Ltd (聯想), which provided 11 percent of its US$26 billion in revenue.

Apple and Ford Motor Co are among its biggest customers.

“We’re out of the computer age and we’re into the age of connected intelligence,” McNamara said while demonstrating the system.

Flextronics’ stock rose 44 percent last year, after the company walked away from low-profit contracts with BlackBerry Ltd and Hewlett-Packard, and invested in the automotive and medical-device markets, at Cross Research analyst Osten Bernardez said.

“They’ve done a very good job of positioning themselves in different, higher-growth markets,” such as making entertainment and lighting systems that car companies used to build themselves, Bernardez said.

Merida Industry Co (美利達) has seen signs of recovery in the US and European markets this year, as customers are gradually depleting their inventories, the bicycle maker told shareholders yesterday. Given robust growth in new orders at its Taiwanese factory, coupled with its subsidiaries’ improving performance, Merida said it remains confident about the bicycle market’s prospects and expects steady growth in its core business this year. CAUTION ON CHINA However, the company must handle the Chinese market with great caution, as sales of road bikes there have declined significantly, affecting its revenue and profitability, Merida said in a statement, adding that it would

Greek tourism student Katerina quit within a month of starting work at a five-star hotel in Halkidiki, one of the country’s top destinations, because she said conditions were so dire. Beyond the bad pay, the 22-year-old said that her working and living conditions were “miserable and unacceptable.” Millions holiday in Greece every year, but its vital tourism industry is finding it harder and harder to recruit Greeks to look after them. “I was asked to work in any department of the hotel where there was a need, from service to cleaning,” said Katerina, a tourism and marketing student, who would

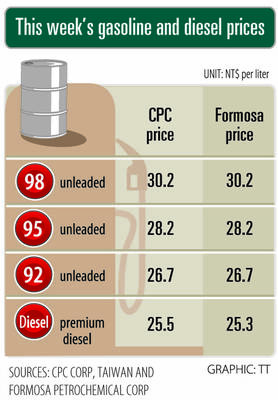

i Gasoline and diesel prices at fuel stations are this week to rise NT$0.1 per liter, as tensions in the Middle East pushed crude oil prices higher last week, CPC Corp, Taiwan (台灣中油) and Formosa Petrochemical Corp (台塑石化) said yesterday. International crude oil prices last week rose for the third consecutive week due to an escalating conflict between Israel and Iran, as the market is concerned that the situation in the Middle East might affect crude oil supply, CPC and Formosa said in separate statements. Front-month Brent crude oil futures — the international oil benchmark — rose 3.75 percent to settle at US$77.01

RISING: Strong exports, and life insurance companies’ efforts to manage currency risks indicates the NT dollar would eventually pass the 29 level, an expert said The New Taiwan dollar yesterday rallied to its strongest in three years amid inflows to the nation’s stock market and broad-based weakness in the US dollar. Exporter sales of the US currency and a repatriation of funds from local asset managers also played a role, said two traders, who asked not to be identified as they were not authorized to speak publicly. State-owned banks were seen buying the greenback yesterday, but only at a moderate scale, the traders said. The local currency gained 0.77 percent, outperforming almost all of its Asian peers, to close at NT$29.165 per US dollar in Taipei trading yesterday. The