At automotive lighting products specialist Depo Auto Parts Industrial Co’s (帝寶工業), production center in Xinying City (新營), Greater Tainan, workers filled 20 containers at once, while trucks came and went constantly.

The center was trying to deliver shipments as quickly as possible to meet rising US demand. In the first two months of this year, the company’s revenue increased 17.3 percent to NT$2.39 billion (US$79.15 million), from NT$2.04 billion a year ago as orders from the nation rose, according to the company’s filing with the Taiwan Stock Exchange.

The utilization rate of the company’s factories is nearly 100 percent, president Hsu Hsu-ming (許敘銘) said.

“It just takes 20 minutes for a lamp to be located in the warehouse and loaded as cargo,” Hsu said on Thursday last week, describing the automation facilities the company installed in its warehouse.

The company is building a logistics center nearby designed to allow the facility to load an additional 30 shipments at once. Construction is scheduled to be completed by the end of this year, Hsu said.

The company is also applying for a construction permit for a seven-floor manufacturing center on another nearby site.

That center is expected to be operational in 2016 and increase Depo’s capacity in Taiwan by 20 percent, Hsu said.

Depo’s Taiwan factories contributed 85 percent of the company’s revenue of NT$13.66 billion last year, with most of the sales coming from auto aftersales markets around the world, the company said.

Xinying is not the only place where Depo is conducting capital expansion, Hsu said.

Planning to have spent about NT$10 billion between last year and 2017, Depo is looking to build a new production facility in Changhua Coastal Industrial Park (彰濱工業區) in Changhua County and improve its centers in Lukang Township (鹿港), Changhua County, and Danyang, Jiangsu Province, China, Hsu said.

According to the company, the NT$10 billion investment project could double Depo’s capacity by the end of 2017.

The company started construction on its first factory in China for the local aftersales market in Danyang in the fourth quarter last year, and the construction will be completed by the end of next year, Hsu said.

Depo’s Chinese factories currently generate 15 percent of the company’s annual revenue by making automobile lamps on a contract basis for Chinese carmakers, the company said.

Depo is to start the first-stage construction of its new production facility on a 12 hectare plot in Changhua Coastal Industrial Park this year, Hsu said.

Each stage of construction is scheduled to take two years, and the new facility will have its own logistics center, manufacturing center and warehouse, Hsu said.

Next year, the company will also rebuild a factory in Lukang, where a fire broke out in August last year, Hsu said.

The company plans to distribute a cash dividend of NT$4 this year, based on its profit of NT$8.06 per share, or NT$1.34 billion, a year ago. Depo plans to save the rest for capital expansion, it said.

The firm will also borrow a syndicated loan of NT$7.2 billion led by state-run Mega International Commercial Bank (兆豐國際商銀) for five years next month for its investment projects, it said.

However, Depo expects its revenue to rise just 3 to 5 percent this year, lower than a 8.2 percent increase it registered a year ago, as sales by its US subsidiary will not perform as in the previous year, because of last year’s higher base.

The company has to wait until next year for its capacity to rise, Hsu said.

In this past quarter, Depo’s revenue was flat, at NT$3.63 billion a quarter ago and up 10 percent from a year ago, it said.

Depo is likely to continue to book depreciation costs for molds this year similar to NT$1.78 billion it registered a year ago, it said.

As the company continue to make new molds, it can make automobile lamps for more cars, increasing its market share, it said.

Last year, the company reported total depreciation costs of NT$2.04 billion, up 13.33 percent from NT$1.8 billion the previous year, it said.

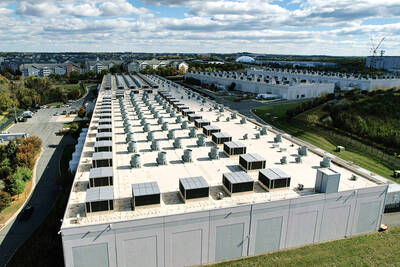

The demise of the coal industry left the US’ Appalachian region in tatters, with lost jobs, spoiled water and countless kilometers of abandoned underground mines. Now entrepreneurs are eyeing the rural region with ambitious visions to rebuild its economy by converting old mines into solar power systems and data centers that could help fuel the increasing power demands of the artificial intelligence (AI) boom. One such project is underway by a non-profit team calling itself Energy DELTA (Discovery, Education, Learning and Technology Accelerator) Lab, which is looking to develop energy sources on about 26,305 hectares of old coal land in

Taiwan’s exports soared 56 percent year-on-year to an all-time high of US$64.05 billion last month, propelled by surging global demand for artificial intelligence (AI), high-performance computing and cloud service infrastructure, the Ministry of Finance said yesterday. Department of Statistics Director-General Beatrice Tsai (蔡美娜) called the figure an unexpected upside surprise, citing a wave of technology orders from overseas customers alongside the usual year-end shopping season for technology products. Growth is likely to remain strong this month, she said, projecting a 40 percent to 45 percent expansion on an annual basis. The outperformance could prompt the Directorate-General of Budget, Accounting and

Netflix on Friday faced fierce criticism over its blockbuster deal to acquire Warner Bros Discovery. The streaming giant is already viewed as a pariah in some Hollywood circles, largely due to its reluctance to release content in theaters and its disruption of traditional industry practices. As Netflix emerged as the likely winning bidder for Warner Bros — the studio behind Casablanca, the Harry Potter movies and Friends — Hollywood’s elite launched an aggressive campaign against the acquisition. Titanic director James Cameron called the buyout a “disaster,” while a group of prominent producers are lobbying US Congress to oppose the deal,

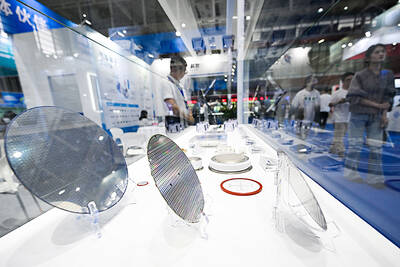

Two Chinese chipmakers are attracting strong retail investor demand, buoyed by industry peer Moore Threads Technology Co’s (摩爾線程) stellar debut. The retail portion of MetaX Integrated Circuits (Shanghai) Co’s (上海沐曦) upcoming initial public offering (IPO) was 2,986 times oversubscribed on Friday, according to a filing. Meanwhile, Beijing Onmicro Electronics Co (北京昂瑞微), which makes radio frequency chips, was 2,899 times oversubscribed on Friday, its filing showed. The bids coincided with Moore Threads’ trading debut, which surged 425 percent on Friday after raising 8 billion yuan (US$1.13 billion) on bets that the company could emerge as a viable local competitor to Nvidia