What did Yves Saint Laurent, Jackie Kennedy and the architect Le Corbusier have in common? Their eyewear, for one, as all three were clients of the luxury French tortoiseshell artisan, Bonnet.

Four decades after trade in tortoiseshell was banned under the 1973 Convention on International Trade in Endangered Species of Wild Fauna and Flora, the fourth-generation family firm sees itself as custodian of a rare craft, fashioning made-to-measure spectacles from stocks amassed before the ban.

Bonnet describes its customers — among them Audrey Hepburn, Maria Callas or former French presidents Francois Mitterrand and Jacques Chirac — as aesthetes who are more concerned about timeless style than fashion.

Photo: AFP

Christian Bonnet, who learned the trade from his father and grandfather, holds the rank of maitre d’art, an honorific title granted by the French Ministry of Culture and currently held by just over 100 craftsmen nationwide.

Today, Bonnet is jointly headed by Christian and his sons Franck and Steven, and turns out about 100 pairs of handmade tortoiseshell glasses per year for prices ranging from 3,500 euros to 30,000 euros (US$4,500 to US$38,600)

“My father didn’t want me to go into the trade, because of the problem with tortoiseshell supply,” Franck Bonnet told reporters, referring to the glasses’ main material: the shell of the endangered hawksbill turtle.

With 12g of tortoiseshell needed for one pair of glasses, the firm says it uses between 2kg to 3kg per year.

Declared part of French national heritage in 2007, Bonnet will not say how much stock it holds, but the supply is finite.

“It is inconceivable that we would ever fish another turtle out of the ocean,” said the 41-year-old, himself a staunch environmentalist.

So he decided a few years ago it was time to look to the future — and to a wider market.

“For my father, my grandfather and great-grandfather before them, it was tortoiseshell, tortoiseshell, tortoiseshell only,” Franck Bonnet said. “I said to my father: ‘You are the last tortoiseshell craftsman, but you are also the last handmade eyewear maker. If we could only use more readily available materials, maybe I can keep our craft alive.’”

That is how in 2008, he introduced buffalo horn into the firm’s product line, which lowered the average frame price to between 1,200 euros and 1,500 euros; and acetate, for budgets between 850 euros and 1,150 euros.

Tortoiseshell aside, the dozen workers at its Paris boutique and workshop in Sens, a few hours southeast of the capital, now produce about 700 pairs using new materials.

The next step toward broadening what they offer is to come from customization — allowing people to change the size and color on standard models.

Franck Bonnet says he loves watching Japanese tourists inspect his wares and is mulling opening a boutique in Tokyo.

“They go over every last detail. You know you haven’t put the effort in for nothing,” he said.

Bonnet was snared in controversy recently when a star journalist, Audrey Pulvar — then in a relationship with a Socialist French minister — was outed for wearing a pair of their steeply priced glasses.

“It wasn’t 12,000 euros, it wasn’t 15,000 euros or 18,000” — as reported in the media — Franck Bonnet said. “Five thousand is more like it.”

In other words, almost an entry-level model.

“It’s true it is costly,” Bonnet said. “But we artisans are not millionaires, this kind of high craft is extremely time-consuming.”

Making glasses to measure means studying the face in minute detail.

“How high your ears are, the shape of your nose — all have an incidence on the tilt of the lenses, and therefore on how well you see,” he said.

This is just the first stage of the process, preceding the multiple steps of shaping and polishing the frame.

“You can spend a crazy length of time on a pair of spectacles, redoing them two, three, five times to get them exactly right. What costs money is not marketing, it’s what goes on the client’s nose,” he said.

On Ireland’s blustery western seaboard, researchers are gleefully flying giant kites — not for fun, but in the hope of generating renewable electricity and sparking a “revolution” in wind energy. “We use a kite to capture the wind and a generator at the bottom of it that captures the power,” said Padraic Doherty of Kitepower, the Dutch firm behind the venture. At its test site in operation since September 2023 near the small town of Bangor Erris, the team transports the vast 60-square-meter kite from a hangar across the lunar-like bogland to a generator. The kite is then attached by a

Foxconn Technology Co (鴻準精密), a metal casing supplier owned by Hon Hai Precision Industry Co (鴻海精密), yesterday announced plans to invest US$1 billion in the US over the next decade as part of its business transformation strategy. The Apple Inc supplier said in a statement that its board approved the investment on Thursday, as part of a transformation strategy focused on precision mold development, smart manufacturing, robotics and advanced automation. The strategy would have a strong emphasis on artificial intelligence (AI), the company added. The company said it aims to build a flexible, intelligent production ecosystem to boost competitiveness and sustainability. Foxconn

Leading Taiwanese bicycle brands Giant Manufacturing Co (巨大機械) and Merida Industry Co (美利達工業) on Sunday said that they have adopted measures to mitigate the impact of the tariff policies of US President Donald Trump’s administration. The US announced at the beginning of this month that it would impose a 20 percent tariff on imported goods made in Taiwan, effective on Thursday last week. The tariff would be added to other pre-existing most-favored-nation duties and industry-specific trade remedy levy, which would bring the overall tariff on Taiwan-made bicycles to between 25.5 percent and 31 percent. However, Giant did not seem too perturbed by the

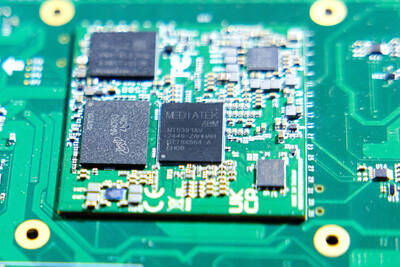

TARIFF CONCERNS: Semiconductor suppliers are tempering expectations for the traditionally strong third quarter, citing US tariff uncertainty and a stronger NT dollar Several Taiwanese semiconductor suppliers are taking a cautious view of the third quarter — typically a peak season for the industry — citing uncertainty over US tariffs and the stronger New Taiwan dollar. Smartphone chip designer MediaTek Inc (聯發科技) said that customers accelerated orders in the first half of the year to avoid potential tariffs threatened by US President Donald Trump’s administration. As a result, it anticipates weaker-than-usual peak-season demand in the third quarter. The US tariff plan, announced on April 2, initially proposed a 32 percent duty on Taiwanese goods. Its implementation was postponed by 90 days to July 9, then