Selling tatamis used to be a profitable business in Hualien, with about 20 shops specializing in manufacturing the Japanese-style straw mats. That was 50 years ago; today, there is only shop left in the east coast city.

Ho Yi-hua (何益華), the 38-year-old proprietor of the last tatami shop in the city, said sales had declined due to changes in social trends, with fewer people using tatamis, as well as competition from machine-made products.

“Demand has dwindled over the decades, and the market has waned considerably,” he said. “The hand-made craft [of making tatamis] is in decline. Other shops shut down one by one over the years.”

Photo: Wang Chin-yi, Taipei Times

Ho inherited his shop, founded more than 60 years ago, from his parents. However, producing handwoven tatamis is labor-intensive and not very profitable, so few people are willing to learn the trade, he said.

“My wish is to pass on my tatami-making skills to my children. If they do not carry it on, then this traditional craft will die with this generation,” he said.

“During their peak in the 1950s, the tatami shops employed about 20 workers each, turning out thousands of mats each year. This went on until the 1980s,” he said.

At the time a standard-sized tatami — about 2m by 1m — sold for NT$900 to NT$1,000.

“Now they sell for NT$4,000 each. Although the price is better, we now only sell about 400 tatamis each year,” he added.

Most of his orders come from old customers, bed-and-breakfast operators or projects in collaboration with interior decorators, he said.

“When covering the rooms and floors with tatami, the most difficult part is the edges and corners. The dimensions must be measured very precisely, otherwise it will leave small gaps,” he said.

“It can get very exhausting, because we have to deliver the tatamis to people’s homes. It is very tiring to carry a tatami weighing more than 20kg and walk up several flights of stairs,” he said.

Ho said it takes about an hour to make a standard-sized tatami. He uses a traditional bamboo-made ruler and set squares — passed down from his grandparents — to measure the dimensions and cuts the core of rice straws to size using a steel knife, then lays on the bamboo mat material and trims the excess.

“After that, I use a steel needle and thick nylon string to lace and bind them up into a mat. Customers choose the color and design for the fabric used to cover the sides,” he said.

Although business has slumped from its peak decades ago, Ho remains optimistic about prospects for handmade tatamis.

“Machine-made tatamis mostly use foam as the base, which can get hot in the summer as it does not dissipate heat well. After using it for a period, the mat looks flat and shrunken. Our handmade tatamis are warm in winter and cool in summer, and have good air permeability,” he said.

“Moreover, fashion is a cycle: Retro styles will become popular again. Our handmade tatamis are more refined, as we pay more attention to details. This can never be replaced by machine-made products,” Ho added.

“This is a precious traditional craft, handed down in my family for several generations. It will take all my life’s effort to carry on this trade, up to the day when my body can no longer take it. I hope this craft can be preserved and passed on for generations to come, ” Ho said.

A group of Taiwanese-American and Tibetan-American students at Harvard University on Saturday disrupted Chinese Ambassador to the US Xie Feng’s (謝鋒) speech at the school, accusing him of being responsible for numerous human rights violations. Four students — two Taiwanese Americans and two from Tibet — held up banners inside a conference hall where Xie was delivering a speech at the opening ceremony of the Harvard Kennedy School China Conference 2024. In a video clip provided by the Coalition of Students Resisting the CCP (Chinese Communist Party), Taiwanese-American Cosette Wu (吳亭樺) and Tibetan-American Tsering Yangchen are seen holding banners that together read:

UNAWARE: Many people sit for long hours every day and eat unhealthy foods, putting them at greater risk of developing one of the ‘three highs,’ an expert said More than 30 percent of adults aged 40 or older who underwent a government-funded health exam were unaware they had at least one of the “three highs” — high blood pressure, high blood lipids or high blood sugar, the Health Promotion Administration (HPA) said yesterday. Among adults aged 40 or older who said they did not have any of the “three highs” before taking the health exam, more than 30 percent were found to have at least one of them, Adult Preventive Health Examination Service data from 2022 showed. People with long-term medical conditions such as hypertension or diabetes usually do not

POLICE INVESTIGATING: A man said he quit his job as a nurse at Taipei Tzu Chi Hospital as he had been ‘disgusted’ by the behavior of his colleagues A man yesterday morning wrote online that he had witnessed nurses taking photographs and touching anesthetized patients inappropriately in Taipei Tzu Chi Hospital’s operating theaters. The man surnamed Huang (黃) wrote on the Professional Technology Temple bulletin board that during his six-month stint as a nurse at the hospital, he had seen nurses taking pictures of patients, including of their private parts, after they were anesthetized. Some nurses had also touched patients inappropriately and children were among those photographed, he said. Huang said this “disgusted” him “so much” that “he felt the need to reveal these unethical acts in the operating theater

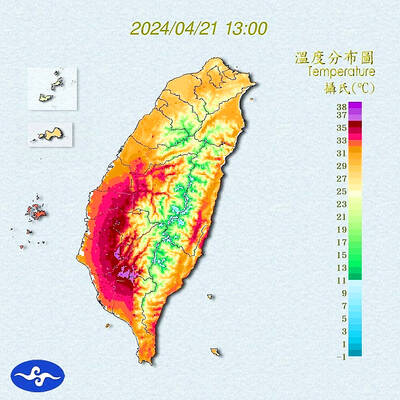

Heat advisories were in effect for nine administrative regions yesterday afternoon as warm southwesterly winds pushed temperatures above 38°C in parts of southern Taiwan, the Central Weather Administration (CWA) said. As of 3:30pm yesterday, Tainan’s Yujing District (玉井) had recorded the day’s highest temperature of 39.7°C, though the measurement will not be included in Taiwan’s official heat records since Yujing is an automatic rather than manually operated weather station, the CWA said. Highs recorded in other areas were 38.7°C in Kaohsiung’s Neimen District (內門), 38.2°C in Chiayi City and 38.1°C in Pingtung’s Sandimen Township (三地門), CWA data showed. The spell of scorching