A Taiwanese businessman is confident of starting a revolution in the food and drink containers industry with a greener alternative to styrofoam containers providing he receives the necessary support from the government and is able to cut costs.

Lin Yi-an (林一安) said styrofoam (polystyrene plastic) containers are convenient because they are light and disposable.

However, he added that styrofoam products are not microwavable and can generate carcinogenic residues when treated with acid or alkali solutions.

As chairman of Changhua County-based Reach Plastic Industrial Co, Lin worked for eight years on developing a non-toxic extruded polypropylene (PP) foam as an alternative to styrofoam packaging.

Because styrofoam is called bao-li-lung (保麗龍) in Mandarin, Lin named the new PP-foam product Taiwan-lung (台灣龍), which means Taiwanese dragon.

Lin said that when people buy coffee at convenience stores, the paper cups are lined with a plastic film to prevent leakage and also have a paper liner for insulation.

However, he said cups made using PP foam are naturally well-insulated and can be filled with hot liquid and held comfortably.

“The product has good insulation properties and can keep contents at the desired temperature,” Lin said.

“Products made from PP foam can withstand temperatures of up to 125oC, are microwavable and can be used in steam cookers,” he said.

“The material is non-toxic, and resistant to acids and alkalis,” Lin added.

Also, because the material is regarded as non-toxic, it is completely recyclable and reusable.

For its extrusion foaming agent, an inorganic gas is used.

Due to these environmentally friendly features, PP foam food containers won the gold prize at the 2009 International Exhibition of Inventions of Geneva, Switzerland.

It was also awarded a prize at an invention competition in Russia, Lin said.

Lin begain his career working in the manufacture of machines for styrofoam production and so is well aware of the material’s toxicity.

He then founded Reach Plastic Industrial Co, which concentrates on research and development (R&D) of food containers.

Because the company is engaged in developing new products, Lin had no point of reference for his research, he said.

Over eight years, the firm invested about NT$10 million (US$340,000) a year in R&D, he added.

In 2007, the company developed the world’s first non-toxic food container made of PP foam.

It commercialized the product in 2011.

However, despite early successes, Lin has encountered a problem: Due to the unique nature of the product, its ingredients must be imported from Austria, making costs NT$0.2 higher per unit compared with styrofoam products.

This has meant that despite buyers often rating the product highly and being impressed with its environmentally-friendly credentials, sales have been lackluster.

The Taiwan Railway Administration had considered using the firm’s PP-foam containers for its lunch boxes, but decided against it because they were more expensive than styrofoam products.

However, Lin remains upbeat about his product and said: “I believe it will not be another eight years of struggle. We will see a major breakthrough this year.”

There are good reasons for his optimism.

The Greater Tainan Government has recently set low-carbon targets and announced that it will ban all polystyrene styrofoam products from July.

Lin has also started researching ways of lowering production costs of PP-foam products.

“The price of raw materials two years ago was twice the current cost. I expect that when new markets open up, and we increase production capacity, we can trim the cost of the products,” he said.

Lin visited many countries while researching styrofoam-producing equipment.

He said that the traditional manufacturing sector in Taiwan has a strong base and develops many high-quality products.

“Some Taiwanese products are even better than those made in Germany. The only difference is the brand value of ‘MIT’ [Made in Taiwan],” he said.

As head of a small enterprise in the manufacturing sector, Lin has committed significant funds to R&D to compete with larger firms and says that more assistance from the government would be welcome.

“The government’s resources are mostly spent on larger firms. We have had to rely on ourselves,” he said.

Lin believes the government should implement policies to gradually ban the use of styrofoam products, so that environmentally-friendly alternatives can become more popular, protecting both the environment and the health of consumers.

A group of Taiwanese-American and Tibetan-American students at Harvard University on Saturday disrupted Chinese Ambassador to the US Xie Feng’s (謝鋒) speech at the school, accusing him of being responsible for numerous human rights violations. Four students — two Taiwanese Americans and two from Tibet — held up banners inside a conference hall where Xie was delivering a speech at the opening ceremony of the Harvard Kennedy School China Conference 2024. In a video clip provided by the Coalition of Students Resisting the CCP (Chinese Communist Party), Taiwanese-American Cosette Wu (吳亭樺) and Tibetan-American Tsering Yangchen are seen holding banners that together read:

UNAWARE: Many people sit for long hours every day and eat unhealthy foods, putting them at greater risk of developing one of the ‘three highs,’ an expert said More than 30 percent of adults aged 40 or older who underwent a government-funded health exam were unaware they had at least one of the “three highs” — high blood pressure, high blood lipids or high blood sugar, the Health Promotion Administration (HPA) said yesterday. Among adults aged 40 or older who said they did not have any of the “three highs” before taking the health exam, more than 30 percent were found to have at least one of them, Adult Preventive Health Examination Service data from 2022 showed. People with long-term medical conditions such as hypertension or diabetes usually do not

POLICE INVESTIGATING: A man said he quit his job as a nurse at Taipei Tzu Chi Hospital as he had been ‘disgusted’ by the behavior of his colleagues A man yesterday morning wrote online that he had witnessed nurses taking photographs and touching anesthetized patients inappropriately in Taipei Tzu Chi Hospital’s operating theaters. The man surnamed Huang (黃) wrote on the Professional Technology Temple bulletin board that during his six-month stint as a nurse at the hospital, he had seen nurses taking pictures of patients, including of their private parts, after they were anesthetized. Some nurses had also touched patients inappropriately and children were among those photographed, he said. Huang said this “disgusted” him “so much” that “he felt the need to reveal these unethical acts in the operating theater

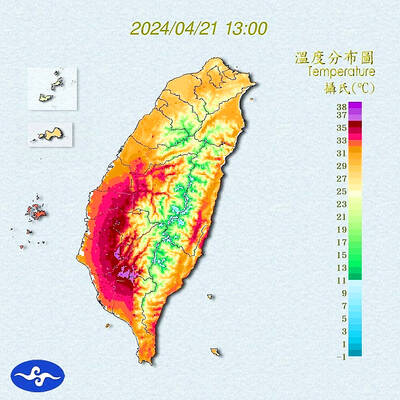

Heat advisories were in effect for nine administrative regions yesterday afternoon as warm southwesterly winds pushed temperatures above 38°C in parts of southern Taiwan, the Central Weather Administration (CWA) said. As of 3:30pm yesterday, Tainan’s Yujing District (玉井) had recorded the day’s highest temperature of 39.7°C, though the measurement will not be included in Taiwan’s official heat records since Yujing is an automatic rather than manually operated weather station, the CWA said. Highs recorded in other areas were 38.7°C in Kaohsiung’s Neimen District (內門), 38.2°C in Chiayi City and 38.1°C in Pingtung’s Sandimen Township (三地門), CWA data showed. The spell of scorching