A joint project between industry and academics funded by the National Science Council has developed new techniques to improve the manufacturing process of GaAs (gallium arsenide) solar cells, which could cut costs by approximately half.

The deputy director of the division of engineering and applied science at the council, Yuen Cheong-wing (阮昌榮), told a press conference yesterday that the project started in December 2009.

Some characteristics of solar cells that counted against them were their high production costs, as well as the energy spent and carbon dioxide emissions involved in their production.

Producing highly efficient, low-cost solar cells in a way that minimizes material waste and carbon dioxide emissions were the objectives of the program, the council said.

Project convener Horng Ray-hua (洪瑞華), a professor at the Graduate Institute of Precision Engineering at National Chung Hsing University, said that in contrast with silicon wafer solar cells or thin-film solar cells, the III-V multi-junction solar cells (GaAs solar cells) showed very high conversion efficiency, at more than 40 percent.

However, because of the relatively expensive cost of the III-V multi-junction solar cell, it is mainly used in artificial satellites or power plants, Horng said. He added that the GaAs substrate was necessary for epitaxial growth — the deposition of a crystalline overlayer on a crystalline substrate — of the cell.

However, the GaAs substrate is expensive and prone to overheating when the cell is functioning, Horng said.

The project’s key achievement was developing a method to separate the GaAs substrate and the crystalline overlayer after the epitaxy process has been completed and the substrate replaced with a copper substrate, which is less expensive and has high thermal capacity.

By enabling the replacement of GaAs substrate, the epitaxial growth time can be shortened, a heat-dissipation mirror can be added and the original GaAs substrate can be reused, cutting total production costs.

The project has applied for five patents and the technology has been transferred to two companies that participated in the collaboration project, Horng said.

A group of Taiwanese-American and Tibetan-American students at Harvard University on Saturday disrupted Chinese Ambassador to the US Xie Feng’s (謝鋒) speech at the school, accusing him of being responsible for numerous human rights violations. Four students — two Taiwanese Americans and two from Tibet — held up banners inside a conference hall where Xie was delivering a speech at the opening ceremony of the Harvard Kennedy School China Conference 2024. In a video clip provided by the Coalition of Students Resisting the CCP (Chinese Communist Party), Taiwanese-American Cosette Wu (吳亭樺) and Tibetan-American Tsering Yangchen are seen holding banners that together read:

UNAWARE: Many people sit for long hours every day and eat unhealthy foods, putting them at greater risk of developing one of the ‘three highs,’ an expert said More than 30 percent of adults aged 40 or older who underwent a government-funded health exam were unaware they had at least one of the “three highs” — high blood pressure, high blood lipids or high blood sugar, the Health Promotion Administration (HPA) said yesterday. Among adults aged 40 or older who said they did not have any of the “three highs” before taking the health exam, more than 30 percent were found to have at least one of them, Adult Preventive Health Examination Service data from 2022 showed. People with long-term medical conditions such as hypertension or diabetes usually do not

POLICE INVESTIGATING: A man said he quit his job as a nurse at Taipei Tzu Chi Hospital as he had been ‘disgusted’ by the behavior of his colleagues A man yesterday morning wrote online that he had witnessed nurses taking photographs and touching anesthetized patients inappropriately in Taipei Tzu Chi Hospital’s operating theaters. The man surnamed Huang (黃) wrote on the Professional Technology Temple bulletin board that during his six-month stint as a nurse at the hospital, he had seen nurses taking pictures of patients, including of their private parts, after they were anesthetized. Some nurses had also touched patients inappropriately and children were among those photographed, he said. Huang said this “disgusted” him “so much” that “he felt the need to reveal these unethical acts in the operating theater

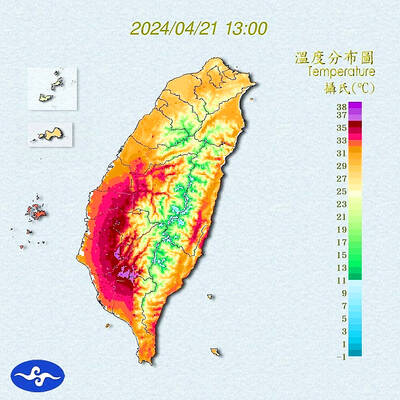

Heat advisories were in effect for nine administrative regions yesterday afternoon as warm southwesterly winds pushed temperatures above 38°C in parts of southern Taiwan, the Central Weather Administration (CWA) said. As of 3:30pm yesterday, Tainan’s Yujing District (玉井) had recorded the day’s highest temperature of 39.7°C, though the measurement will not be included in Taiwan’s official heat records since Yujing is an automatic rather than manually operated weather station, the CWA said. Highs recorded in other areas were 38.7°C in Kaohsiung’s Neimen District (內門), 38.2°C in Chiayi City and 38.1°C in Pingtung’s Sandimen Township (三地門), CWA data showed. The spell of scorching