This SD-40 locomotive has hauled freight across North America’s heartland for over 40 years. Now it’s reached the end of the line. One hundred tonnes of steel, six sets of wheels and a fourteen-and-a-half-tonne engine must be salvaged, melted or refurbished, so it can be reborn and returned to the rail industry.

這列SD-40火車頭在北美中部拖貨櫃已超過四十年,如今已屆退休之年。一百公噸鋼鐵、六對車輪及十四點五公噸重的引擎必須被拆解、鎔化或翻新,如此才能再生,然後返回鐵路工業。

Railroads are the backbone of American industry. Over 270,000km of track crisscross the country from coast to coast moving nearly two billion tonnes of freight every year. At the center of it all sits Kansas City, the second largest rail junction in the US. Two hundred thousand trains pass through this location every year. But today, two locomotives owned by Kansas City Southern — or KCS — will stop running. Numbers 672 and 605 have been on the rails for over 40 years. But now their engine technology is inefficient and fuel prices are at an all-time high so these locomotives are headed for the scrap yard to be broken down.

鐵路是美國工業的骨幹,從東岸到西岸,超過二十七萬公里長的鐵軌交叉遍布全國,每年搬運將近二十億公噸貨物。其中心是美國第二大鐵路樞紐堪薩斯市,每年有二十萬列火車經過此地,但如今堪薩斯市南方鐵路公司(簡稱KCS),所擁有的兩列火車頭將停止營運。672和605號火車頭,已在鐵軌上跑了四十多年,但如今它們的引擎技術效能不彰,加上燃料價格來到歷史新高,因此這兩列火車頭要前往報廢場被分解。

Scrap and recycling company Erman usually scraps much lighter train equipment so this locomotive pair is almost too much for the rails to handle. They’ll need to systematically dismantle the locomotives, cutting through solid steel without damaging the internal components or their auxiliary parts. A locomotive is designed to be almost indestructible — in this case, a 160-tonne construction of cast and welded steel. Each piece must be taken out by hand with blowtorches. The breakdown will happen from the top down in three steps. Step one, the strip down: cut and skin the steel outer shell of the locomotive to expose its power core. Step two, the gut out: remove the locomotive’s internal organs — the prime mover and generator. And step three, the final breakdown: cut away the cab, and torch up the over seven-centimeter-thick solid steel locomotive bed to salvage the wheels and supports. It’s a job that takes experience, skill and a healthy respect for locomotives.

爾曼企業拆解的多半是比較輕的火車設備,這對火車頭對鐵軌而言是過於沉重的負擔。他們需要有計畫地拆解火車頭,以不破壞內部組件或附屬零件的方式切割鋼鐵,火車頭的設計幾乎無法破壞。這列火車頭是由一百六十公噸的鑄鋼製造而成,每塊鑄鋼都要用焊槍精準地拆解開來,拆解方式由上而下,分為三個步驟。第一步,拆除外殼:切割拆除火車頭的鋼鐵外殼,露出內部的動力核心。第二步,取出內部裝置:移除火車頭的內部機件──原動機和發電機。第三步,最後的解體:切除駕駛室,用焊槍切開超過七公分厚的鋼鐵火車頭底層,好拆解輪胎和支架。這是一項需要經驗、技術和對火車頭心存敬意的工作。

Number 672 will be the first to go. The team needs to cut through layers of solid steel and blowtorches are the only way to do it. The flame is 50 percent acetylene gas and 50 percent oxygen — the only mixture that burns hot enough to cut steel, 3,480ºC to be exact. Direct contact with this heat could be deadly, so each worker must wear a face shield and protective clothing. But the flames aren’t the only hazard. A machine this old is a potential powder keg. Oil and fuel residues are all over this locomotive. One wrong move with a blowtorch could ignite an explosion.

首先要拆解的是672號。工作團隊要切開鋼鐵,唯一可行的方式是使用焊槍,火焰含有百分之五十乙炔和百分之五十氧氣,這是唯一能燃燒到可切割鋼鐵的混合物,正確的溫度是攝氏三千四百八十度。直接接觸如此的高溫有致命危險,每個工人都必須穿戴面部防護罩和稱為皮衣的防護衣。但火焰並非唯一的危險,如此老舊的機器很容易變成火藥桶,火車頭上到處都有油和燃料的殘餘物,焊槍一個不小心就會引爆。

In an effort to fight phone scams, British mobile phone company O2 has introduced Daisy, an AI designed to engage phone con artists in time-wasting conversations. Daisy is portrayed as a kindly British granny, exploiting scammers’ tendency to target the elderly. Her voice, based on a real grandmother’s for authenticity, adds to her credibility in the role. “O2” has distributed several dedicated phone numbers online to direct scammers to Daisy instead of actual customers. When Daisy receives a call, she translates the scammers’ spoken words into text and then responds to them accordingly through a text-to-speech system. Remarkably, Daisy

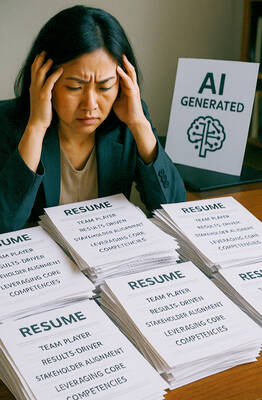

Bilingual Story is a fictionalized account. 雙語故事部分內容純屬虛構。 Emma had reviewed 41 resumes that morning. While the ATS screened out 288 unqualified, she screened for AI slop. She could spot it a mile away. She muttered AI buzzwords like curses under her breath. “Team player.” “Results-driven.” “Stakeholder alignment.” “Leveraging core competencies.” Each resume reeked of AI modeling: a cemetery of cliches, tombstones of personality. AI wasn’t just changing hiring. It was draining the humanity from it. Then she found it: a plain PDF cover letter. No template. No design flourishes. The first line read: “I once tried to automate my

Every May 1, Hawaii comes alive with Lei Day, a festival celebrating the rich culture and spirit of the islands. Initiated in 1927 by the poet Don Blanding, Lei Day began as a tribute to the Hawaiian custom of making and wearing leis. The idea was quickly adopted and officially recognized as a holiday in 1929, and leis have since become a symbol of local pride and cultural preservation. In Hawaiian culture, leis are more than decorative garlands made from flowers, shells or feathers. For Hawaiians, giving a lei is as natural as saying “aloha.” It shows love and

1. 他走出門,左右看一下,就過了馬路。 ˇ He walked outside, looked left and right, and crossed the road. χ He walked outside and looked left and right, crossed the road. 註︰並列連接詞 and 在這句中連接三個述語。一般的結構是 x, y, and z。x and y and z 是加強語氣的結構,x and y, z 則不可以。 2. 他們知道自己的弱點以及如何趕上其他競爭者。 ˇ They saw where their weak points lay and how they could catch up with the other competitors. χ They saw where their weak points lay and how to catch up with the other competitors. 註:and 一般連接同等成分,結構相等的單詞、片語或子句。誤句中 and 的前面是子句,後面是不定詞片語,不能用 and 連接,必須把不定詞片語改為子句,and 前後的結構才相等。 3. 她坐上計程車,直接到機場。 ˇ She took a cab, which took her straight to the airport. ˇ She took a cab and it took her straight