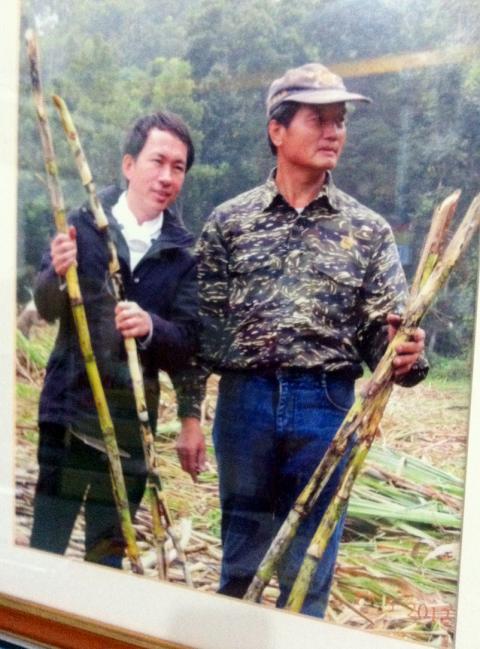

Chang Hsi-bin (張錫斌) has been keeping the same wakeup schedule for the past decade. He rises at 2:30am, and slides into a freshly ironed camouflage suit and boots before venturing out in the dark to start his day. And though Chang’s routine is fairly regimented, he’s no military man.

“I feel more vigorous when I am in camouflage shirts,” the 57-year-old sugar maker smiled timidly when asked about his eye-catching attire.

“Making black sugar from scratch is hard work and requires precision, skill and commitment,” he said, “At the end of the day, though, it’s all worth it because you know what you are putting into your stomach.”

Photo: Nancy Liu

Chang remembers that when he started his small black sugar factory in his backyard 11 years ago, few expressed interest in his labor of love. Consumers purchased sugar, as well as other condiments, based on price and his black crystals were just too expensive: NT$220 per 500g, almost 10 times the price of sugar made in large industrial-scale refineries.

CONSUMER FOOD SCARES

The odds were against him until a succession of high profile food scares that have consumers questioning the safety of artificially processed food. Now his product, which has no preservatives added, is winning the heart of shoppers as far away as China and Russia. Chang’s handmade black sugar factory has grown to become the largest in Taiwan, generating NT$20 million in revenue last year.

Photo: Nancy Liu

To ensure stable production growth and to revive the black sugar industry, Chang formed contract farming agreements with 20-plus farmers to grow eco-friendly sugarcane. After harvest, the fresh sugarcane is transported to the factory for more than 7 hours of squeezing, heating, cooling and packaging.

“The sugar you see here has no negative effect on our bodies or the environment,” Chang said, motioning to a pot of syrup he had been continuously stirring for an hour. “The most difficult part of the whole process is boiling the syrup to the right temperature. You want it to caramelize but you don’t want it burnt. This is all about experience.”

He added that machines could be used to stir the syrup and control the temperature of the woodstove, “but the taste won’t be the same.” Chang said the taste he is trying so hard to preserve is the taste of traditional Taiwanese sugar.

Photo: Nancy Liu

GROWING DEMAND

According to government statistics, Taiwan’s current demand for sugar is about 550,000 to 600,000 metric tons per year, of which 90 percent is imported. Things were very different a century ago, when sugar-making was the main industry. Japan, after claiming the nation as a colony in 1895, saw the lucrative possibilities in sugar export and established sugar refineries nationwide to process crops procured from local farmers.

By 1939, 30 percent of Taiwanese farmers were growing sugarcane, producing 1.4 million metric tons for 49 factories. At the end of World War II, Taiwan’s sugar export was said to have contributed to more than 50 percent of the export income, earning it the title of “Sugar Cane Kingdom.”

Photo: Nancy Liu

Chang’s father was one of the farmers who sold his crops to Japanese sugar manufacturers.

“Sometimes villagers would make black sugar for us kids and the taste was incomparable,” Chang said, adding that at the time sugar-making was a heavily restricted state-run industry. But because Kuanshan (關山) was located in the mountains and without roads, it was possible to refine the sugar in secret.

LABOR DRAIN

Today, however, there are greater concerns facing this old generation of farmers.

“Young people have all left for the cities and don’t want to stay,” said Hsieh Yong-fu (謝永福), a former high speed rail construction worker who now works at the factory. Young people would rather work in an air conditioned office, rather than under the blazing sun. Better job opportunities — preferably ones that can preserve local traditions and revitalize the farming economy — are needed, the 58-year-old said.

The average age of Taiwanese farmers is 63 and the lack of new blood is threatening the development of farming communities. To address this, the Ministry of Agriculture is planning on introducing foreign laborers into the farming industry sometime in the near future.

Growing up in the village, Chang’s son understands the predicament well. Rather than shying away from the challenge, Chang Yue-teng (張月騰) decided to embrace it. After graduating from college, he returned to help shoulder the task of passing on the genuine taste of Taiwan’s sugar.

“I came back without a second thought because this is where I belong,” the 27-year-old said.

Besides working in the field, Chang is also in charge of Internet marketing, hoping to make known the value of Taiwanese black sugar to more people. With a resolute look in his eyes, he said this is a mission that must be accomplished.

“After all, it would be a pity to let this tradition die out, wouldn’t it,” he asked, knowing very well the answer to his question.

In late October of 1873 the government of Japan decided against sending a military expedition to Korea to force that nation to open trade relations. Across the government supporters of the expedition resigned immediately. The spectacle of revolt by disaffected samurai began to loom over Japanese politics. In January of 1874 disaffected samurai attacked a senior minister in Tokyo. A month later, a group of pro-Korea expedition and anti-foreign elements from Saga prefecture in Kyushu revolted, driven in part by high food prices stemming from poor harvests. Their leader, according to Edward Drea’s classic Japan’s Imperial Army, was a samurai

The following three paragraphs are just some of what the local Chinese-language press is reporting on breathlessly and following every twist and turn with the eagerness of a soap opera fan. For many English-language readers, it probably comes across as incomprehensibly opaque, so bear with me briefly dear reader: To the surprise of many, former pop singer and Democratic Progressive Party (DPP) ex-lawmaker Yu Tien (余天) of the Taiwan Normal Country Promotion Association (TNCPA) at the last minute dropped out of the running for committee chair of the DPP’s New Taipei City chapter, paving the way for DPP legislator Su

It’s hard to know where to begin with Mark Tovell’s Taiwan: Roads Above the Clouds. Having published a travelogue myself, as well as having contributed to several guidebooks, at first glance Tovell’s book appears to inhabit a middle ground — the kind of hard-to-sell nowheresville publishers detest. Leaf through the pages and you’ll find them suffuse with the purple prose best associated with travel literature: “When the sun is low on a warm, clear morning, and with the heat already rising, we stand at the riverside bike path leading south from Sanxia’s old cobble streets.” Hardly the stuff of your

April 22 to April 28 The true identity of the mastermind behind the Demon Gang (魔鬼黨) was undoubtedly on the minds of countless schoolchildren in late 1958. In the days leading up to the big reveal, more than 10,000 guesses were sent to Ta Hwa Publishing Co (大華文化社) for a chance to win prizes. The smash success of the comic series Great Battle Against the Demon Gang (大戰魔鬼黨) came as a surprise to author Yeh Hung-chia (葉宏甲), who had long given up on his dream after being jailed for 10 months in 1947 over political cartoons. Protagonist