US-based WeWork Companies Inc, which is rebranding to The We Co, on Thursday announced its entry into Taiwan, starting with an office-sharing business at a building in Taipei’s Xinyi District (信義).

The company has targeted several floors in a building on Songren Road and said that it is in talks with potential tenants, WeWork Asia vice chairman Christian Lee told a news conference in Taipei.

With a significant number of innovative start-ups in the Xinyi District, Lee said that his team would seek out partnerships, without giving names.

The company also did not provide its sales target for the local market or plans for other cities in Taiwan.

Founded in 2010, WeWork mainly leases real estate such as office buildings and designs shared workspaces for individuals and enterprises.

The company has quickly expanded to 28 countries and now boasts 485 locations in 105 cities from the Americas to Asia.

“Around 40 percent of our members in Asia-Pacific are large enterprises, and the remaining 60 percent are small companies with less than 10 employees,” Lee said, adding that the company has more than 400,000 members.

While the company boasts members from Fortune 500 companies, up to one-third of which are using WeWork, Lee said his company presents an advantage to smaller companies.

“You can just walk in an office and start working without signing a five-year lease... That’s a huge time-saver for small companies,” he said.

The company, which counts Japan’s Softbank Group Corp among its major investors, last year doubled its revenue to US$1.82 billion thanks to overseas sales, while also doubling its losses to US$1.93 billion, Bloomberg News reported.

Almost half of the company’s first-quarter revenue of US$728 million came from overseas sales, up from 38 percent last year, while losses totaled US$264 million in the quarter, Bloomberg said.

Nvidia Corp chief executive officer Jensen Huang (黃仁勳) on Monday introduced the company’s latest supercomputer platform, featuring six new chips made by Taiwan Semiconductor Manufacturing Co (TSMC, 台積電), saying that it is now “in full production.” “If Vera Rubin is going to be in time for this year, it must be in production by now, and so, today I can tell you that Vera Rubin is in full production,” Huang said during his keynote speech at CES in Las Vegas. The rollout of six concurrent chips for Vera Rubin — the company’s next-generation artificial intelligence (AI) computing platform — marks a strategic

REVENUE PERFORMANCE: Cloud and network products, and electronic components saw strong increases, while smart consumer electronics and computing products fell Hon Hai Precision Industry Co (鴻海精密) yesterday posted 26.51 percent quarterly growth in revenue for last quarter to NT$2.6 trillion (US$82.44 billion), the strongest on record for the period and above expectations, but the company forecast a slight revenue dip this quarter due to seasonal factors. On an annual basis, revenue last quarter grew 22.07 percent, the company said. Analysts on average estimated about NT$2.4 trillion increase. Hon Hai, which assembles servers for Nvidia Corp and iPhones for Apple Inc, is expanding its capacity in the US, adding artificial intelligence (AI) server production in Wisconsin and Texas, where it operates established campuses. This

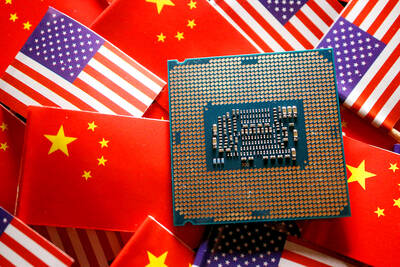

US President Donald Trump on Friday blocked US photonics firm HieFo Corp’s US$3 million acquisition of assets in New Jersey-based aerospace and defense specialist Emcore Corp, citing national security and China-related concerns. In an order released by the White House, Trump said HieFo was “controlled by a citizen of the People’s Republic of China” and that its 2024 acquisition of Emcore’s businesses led the US president to believe that it might “take action that threatens to impair the national security of the United States.” The order did not name the person or detail Trump’s concerns. “The Transaction is hereby prohibited,”

Garment maker Makalot Industrial Co (聚陽) yesterday reported lower-than-expected fourth-quarter revenue of NT$7.93 billion (US$251.44 million), down 9.48 percent from NT$8.76 billion a year earlier. On a quarterly basis, revenue fell 10.83 percent from NT$8.89 billion, company data showed. The figure was also lower than market expectations of NT$8.05 billion, according to data compiled by Yuanta Securities Investment and Consulting Co (元大投顧), which had projected NT$8.22 billion. Makalot’s revenue this quarter would likely increase by a mid-teens percentage as the industry is entering its high season, Yuanta said. Overall, Makalot’s revenue last year totaled NT$34.43 billion, down 3.08 percent from its record NT$35.52