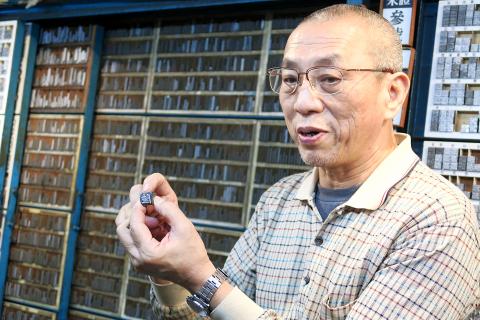

Chang Chieh-kuan (張介冠), the owner of the last Chinese character letterpress and the last lead-character moldmaker in Taiwan, has long dreamed about passing on his work so that the dying technique of which he is a master practitioner can be preserved.

However, just days before his humble shop, Rixing Type Foundry (日星鑄字行), squeezed into a small lane on Taipei’s Taiyuan Road (太原路), celebrated its 48th anniversary yesterday, 65-year-old Chang came to believe those hopes were a pipe dream and that it would be impossible to cultivate such talent.

“I will just carve as long as I can,” Chang said, as he strives to preserve the culture of Chinese letterpress printing against the passing of time and advent of new technology.

Photo: CNA

Rixing Type Foundry is possibly home to the last remaining collection of traditional Chinese movable type character molds in the world. It possesses 120,000 molds of different characters in a wide range of sizes and three different typefaces — kai ti (楷體) (regular script), song ti (宋體) and hei ti (黑體) (sans-serif black) — and has more than 10 million lead character pieces for printing or sale.

The foundry also has several molding machines that allow it to fabricate 3D lead type pieces, making it the last and only foundry of its kind in Taiwan.

However, the business might fade into history because many of its bronze molds are either partly or wholly worn.

What makes the situation even more daunting, as Chang has long feared, is that there is no way to train anyone in the skills needed to repair bronze molds for lead type.

It was in 1979 when Chang, a trained steel mechanic, started working at the lead foundry his father opened in 1969.

Training in the crafting and mending of lead type bronze molds should really start at 12 or 13, because it takes 10 to 15 years to master the skills, he said.

In addition, traditional masters remain at the peak of their abilities for about 10 years, at which point they have to rely more on experience as their eyesight deteriorates, Chang said.

“These days it is impossible to acquire apprentices aged 12 or 13. If people come here after graduating from college or university, their eyesight is already not good enough to do the job,” Chang said.

Joking that he was “forced” to enter the business, the lead type foundry master said he now often spends most of the day at his desk, mending the worn molds.

However, he said he never grows tired of the repetitive nature of tasks such as recrafting, scanning and correcting character types, which can seem extremely monotonous to an outsider. “I do not know how long the bronze molds at Rixing will last, as many of them are already badly worn,” Chang said. “I am now 65 years old. It will take another 65 years to repair them all.”

A skilled foundry master can mend a maximum of five character molds per day, he said, adding that to restore all 120,000 molds at Rixing Foundry would be extremely expensive.

Despite the time-consuming and labor intensive nature of the work, Chang told visitors to his shop that lead type imbues Chinese characters with a grandeur that digital printing cannot replicate.

It is like the difference between listening to music on vinyl or CD; it is all about the warm sentiment lead type conveys, he said.

Early this year Rixing launched a type bronze mold restoration project in the hope that an online fundraising program would help raise the funds needed to preserve its endangered bronze molds so that they can be passed on in their entirety.

“We want not only to preserve lead type, but also an era,” Chang said in a post on the project’s Web site at rixing2017.com.

“The ideal situation would be for people to express their support for the preservation of this culture through their everyday life choices,” he said.

SEEKING CLARITY: Washington should not adopt measures that create uncertainties for ‘existing semiconductor investments,’ TSMC said referring to its US$165 billion in the US Taiwan Semiconductor Manufacturing Co (TSMC, 台積電) told the US that any future tariffs on Taiwanese semiconductors could reduce demand for chips and derail its pledge to increase its investment in Arizona. “New import restrictions could jeopardize current US leadership in the competitive technology industry and create uncertainties for many committed semiconductor capital projects in the US, including TSMC Arizona’s significant investment plan in Phoenix,” the chipmaker wrote in a letter to the US Department of Commerce. TSMC issued the warning in response to a solicitation for comments by the department on a possible tariff on semiconductor imports by US President Donald Trump’s

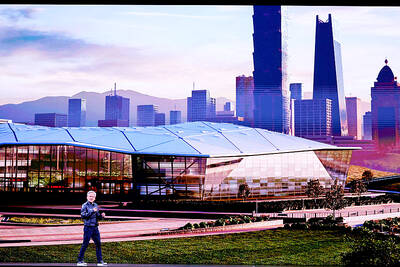

The government has launched a three-pronged strategy to attract local and international talent, aiming to position Taiwan as a new global hub following Nvidia Corp’s announcement that it has chosen Taipei as the site of its Taiwan headquarters. Nvidia cofounder and CEO Jensen Huang (黃仁勳) on Monday last week announced during his keynote speech at the Computex trade show in Taipei that the Nvidia Constellation, the company’s planned Taiwan headquarters, would be located in the Beitou-Shilin Technology Park (北投士林科技園區) in Taipei. Huang’s decision to establish a base in Taiwan is “primarily due to Taiwan’s talent pool and its strength in the semiconductor

An earnings report from semiconductor giant and artificial intelligence (AI) bellwether Nvidia Corp takes center stage for Wall Street this week, as stocks hit a speed bump of worries over US federal deficits driving up Treasury yields. US equities pulled back last week after a torrid rally, as investors turned their attention to tax and spending legislation poised to swell the US government’s US$36 trillion in debt. Long-dated US Treasury yields rose amid the fiscal worries, with the 30-year yield topping 5 percent and hitting its highest level since late 2023. Stocks were dealt another blow on Friday when US President Donald

UNCERTAINTY: Investors remain worried that trade negotiations with Washington could go poorly, given Trump’s inconsistency on tariffs in his second term, experts said The consumer confidence index this month fell for a ninth consecutive month to its lowest level in 13 months, as global trade uncertainties and tariff risks cloud Taiwan’s economic outlook, a survey released yesterday by National Central University found. The biggest decline came from the timing for stock investments, which plunged 11.82 points to 26.82, underscoring bleak investor confidence, it said. “Although the TAIEX reclaimed the 21,000-point mark after the US and China agreed to bury the hatchet for 90 days, investors remain worried that the situation would turn sour later,” said Dachrahn Wu (吳大任), director of the university’s Research Center for