Taiwan’s recycling systems are labor intensive. In residential neighborhoods, scavengers collect bento boxes, cans, cardboard and PET bottles, and sell them onto nearby recycling yards where they are weighed and bundled before dispatch to resource recovery plants.

Most of the scavengers, and many of those who work in the yards, are in their sixties or older. They epitomize the country’s aging and shrinking labor pool.

When decrepitude eventually removes them from the workforce, it isn’t obvious who’ll gather recyclables from people who are too busy or too lazy to bring them out when municipal garbage trucks do their rounds. In recent years, the government has expanded welfare payments and senior-citizen stipends, so it’s uncertain whether many Taiwanese now in their fifties will show an interest in this kind of work when they reach retirement age.

Photo: Steven Crook

Hiring foreign laborers could be one way to plug the gap, but automation and AI may offer a solution that’s more palatable to local voters.

SMART RECYCLING MACHINES

President Chain Store Corp (PCSC), which operates Taiwan’s 7-Eleven convenience stores, aims to install “Efficient and Intelligent Recycling Machines” at 200 locations across the country by the end of this year.

Photo courtesy of President Chain Store Corp

Such machines are much more sophisticated than the reverse vending machines (RVMs) for aluminum cans and beverage bottles that have been common in many developed countries since the 1960s. The 82,000 RVMs manufactured by Norway-based TOMRA Systems process more than 45 billion empty cans and bottles every year, TOMRA’s Web site says.

According to e-mailed answers provided by President, the 7-Eleven machines — which can handle PET bottles and dry batteries — were developed in conjunction with President Packaging Corp to implement the company’s plastics reduction initiative.

Thanks to a patented combination of AI, optical imaging and material-recognition technology, each RVM is able to separate bottles from batteries, and reject unsuitable plastics, such as HDPE, or PET bottles which contain sauce or oil. There’s no need to strip bottles of their wraparound labels before dropping them into one of the Efficient and Intelligent Recycling Machines.

Photo: Hung Mei-hsiu, Taipei Times

Bottles can be square or round, and must be between 250ml and 2000ml in size. The machines can receive common battery types such as AA and AAA, but not button cells or smartphone power-banks.

The machines grind PET bottles into flakes. This not only reduces the volume of plastic to be recycled by up to 75 percent, but also shrinks the carbon footprint of transporting it to a plant where it’ll be sorted and transformed into materials that’ll end up in shoes, sports apparel and outdoor furniture.

The 10,000-plus members of the public who’d deposited more than two million bottles and batteries in 7-Eleven recycling machines by early May this year weren’t inspired only by environmentalist sentiments. Each time a customer exchanges five PET bottles or five batteries at a machine, he or she can receive a NT$1 shopping credit or one point in PCSC’s OPEN POINT reward scheme. What’s more, the company points out, because the RVMs are accessible 24/7, they make it easier for busy individuals to live a more sustainable lifestyle.

Photo courtesy of President Chain Store Corp

7-Eleven’s machines supplement a recycling system that the chain has been operating for well over a decade, but which hitherto required the involvement of a human employee every time recyclables were brought in.

According to 7-Eleven’s Web site, customers can redeem a defunct laptop for a NT$120 shopping credit. For a cellphone, they can get NT$12. For a cellphone charger, the credit is NT$3. If they bring in 500g of batteries, they’ll receive NT$8. But if the quantity is just under 500g, they’ll get nothing, and they’d be better off using one of the new machines.

(President declines to reveal the total quantity of batteries or other items 7-Eleven receives this way each year, how much it pays out in shopping credits or if it receives any government subsidies for handling recyclables.)

‘ECOFRIENDLY COIN’

Since late 2018, a Tainan-based startup has also been rolling out machines that award shopping points in return for recyclables. Fun Lead Change Co’s ECOCO machines, which are a distinctive shade of orange, have been installed at around 90 locations in 15 of Taiwan’s 22 special municipalities, counties and cities.

The name ECOCO derives from the words “ecofriendly” and “coin,” but the machines don’t reward users with actual coins. Anyone who’s downloaded the ECOCO smartphone app can insert PET bottles and certain items to accumulate points that can be used to offset purchases at 40-plus partner brands.

Partners include Everrich (which operates duty-free stores at airports), the EZ.Kon restaurant chain, Family Mart, Foodpanda and eyeglasses chain Kobayashi Optical. Different enterprises offer different rates of exchange. Some give users a NT$1 discount for 2 ECOCO points, while others give the same discount for 8 ECOCO points.

Businesses that host ECOCO machines — they may or may not be brands at which users can redeem points — rent them from Fun Lead Change, which then purchases all of the recyclables that users deposit. The company then sells those bottles and batteries to recycling plants like the one operated by Remondis Taiwan Co in Nantou County (see “Reducing Taiwan’s virgin plastics” in the May 25, 2022 edition of this newspaper).

“At first, it was difficult to get people to understand and accept our business model. Nowadays, it’s easier for us to persuade entrepreneurs to join us, because we’ve proved our model can work well in several different situations,” says Josie Chen (陳怡絪), a spokesperson for Fun Lead Change.

According to the company’s Web site, by the end of last year, ECOCO machines had processed 2,418 metric tons of recyclables, “equivalent to planting more than 250,000 trees, with about 6.2 times the annual carbon-absorption benefits of Daan Forest Park (大安森林公園).”

MAINTENANCE AND USE

The machines aren’t cheap. The first batch of RVMs was purchased from TOMRA and cost around NT$900,000 each, Chen says. The company is now deploying machines that were designed in-house and manufactured in Tainan, among them battery RVMs which cost NT$450,000 apiece. These don’t require much space, as they’re just 40cm wide, 48cm deep and 160cm tall.

Daily routine maintenance is so straightforward it can be done by an employee of the host business. How often an ECOCO technician needs to visit a particular site is influenced by how much the machine gets used, Chen says.

ECOCO users should remove labels from bottles, and put bottle caps in a separate opening. Batteries that are corroded or deformed will be rejected by the machine.

For Tainan City Government’s Environment Protection Bureau, Fun Lead Change this spring upgraded a recycling point outside a hypermarket in West Central District (中西) into a 24-hour “smart” facility. It handles aluminum cans, glass bottles (so long as they’re 8 to 38cm in length and 5 to 11cm in diameter) and PP beverage cups, as well as PET bottles and old batteries.

Tainan isn’t the only local government showing interest in this sort of technology. As reported by this newspaper (“‘Smart’ plant speeds up recycling in New Taipei City,” March 15), earlier this year the New Taipei City Government Environmental Protection Bureau began using a combination of optical and magnetic devices, robotics and AI at a facility in Wugu District (五股). The system can identify and separate 17 different kinds of recyclable materials, including paper, various metals and plastics such as PE, PP and polystyrene.

Recycling has never been easier, but some people still don’t make the effort. Research published in the July 2019 issue of the Journal of Marketing suggests that informing consumers about the specific uses of recovered materials is more likely to inspire them to recycle than vague messages about saving the Earth.

That’s very likely true — but appealing to people’s desire to get something for near-nothing, which is central to the ECOCO and 7-Eleven systems, is perhaps even more effective.

Steven Crook, the author or co-author of four books about Taiwan, has been following environmental issues since he arrived in the country in 1991. He drives a hybrid and carries his own chopsticks. The views expressed here are his own.

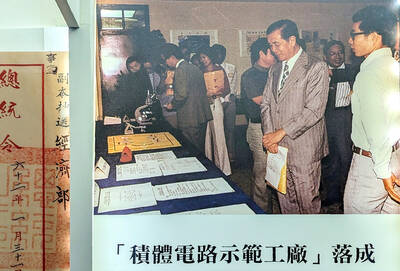

Oct. 27 to Nov. 2 Over a breakfast of soymilk and fried dough costing less than NT$400, seven officials and engineers agreed on a NT$400 million plan — unaware that it would mark the beginning of Taiwan’s semiconductor empire. It was a cold February morning in 1974. Gathered at the unassuming shop were Economics minister Sun Yun-hsuan (孫運璿), director-general of Transportation and Communications Kao Yu-shu (高玉樹), Industrial Technology Research Institute (ITRI) president Wang Chao-chen (王兆振), Telecommunications Laboratories director Kang Pao-huang (康寶煌), Executive Yuan secretary-general Fei Hua (費驊), director-general of Telecommunications Fang Hsien-chi (方賢齊) and Radio Corporation of America (RCA) Laboratories director Pan

The classic warmth of a good old-fashioned izakaya beckons you in, all cozy nooks and dark wood finishes, as tables order a third round and waiters sling tapas-sized bites and assorted — sometimes unidentifiable — skewered meats. But there’s a romantic hush about this Ximending (西門町) hotspot, with cocktails savored, plating elegant and never rushed and daters and diners lit by candlelight and chandelier. Each chair is mismatched and the assorted tables appear to be the fanciest picks from a nearby flea market. A naked sewing mannequin stands in a dimly lit corner, adorned with antique mirrors and draped foliage

The consensus on the Chinese Nationalist Party (KMT) chair race is that Cheng Li-wun (鄭麗文) ran a populist, ideological back-to-basics campaign and soundly defeated former Taipei mayor Hau Lung-bin (郝龍斌), the candidate backed by the big institutional players. Cheng tapped into a wave of popular enthusiasm within the KMT, while the institutional players’ get-out-the-vote abilities fell flat, suggesting their power has weakened significantly. Yet, a closer look at the race paints a more complicated picture, raising questions about some analysts’ conclusions, including my own. TURNOUT Here is a surprising statistic: Turnout was 130,678, or 39.46 percent of the 331,145 eligible party

The election of Cheng Li-wun (鄭麗文) as chair of the Chinese Nationalist Party (KMT) marked a triumphant return of pride in the “Chinese” in the party name. Cheng wants Taiwanese to be proud to call themselves Chinese again. The unambiguous winner was a return to the KMT ideology that formed in the early 2000s under then chairman Lien Chan (連戰) and president Ma Ying-jeou (馬英九) put into practice as far as he could, until ultimately thwarted by hundreds of thousands of protestors thronging the streets in what became known as the Sunflower movement in 2014. Cheng is an unambiguous Chinese ethnonationalist,