Toyota Motor Corp sold 10.8 million cars last year, a slight drop from the previous year, but more than enough to protect its title against Volkswagen AG as the world’s biggest carmaker for a fifth consecutive year.

While global sales — including from subsidiaries Daihatsu Motor Co and Hino Motors Ltd — fell 3.7 percent year-on-year last year, that was still enough for Toyota to stay ahead of VW, which delivered just over 9 million cars last year, a 2.3 percent decline from the year before.

Toyota had a troublesome year after safety scandals at a pair of subsidiaries disrupted production for months. While the company’s bet that demand for gas-guzzlers and hybrids will hold up in the face of electric vehicles (EVs), emerging rivals like China’s BYD Co (比亞迪) are rapidly making inroads to the global auto market. BYD sold 4.3 million cars last year — including 1.8 million EVs — a 41 percent jump from the previous year.

Photo: Reuters

In contrast, Toyota sold just 139,892 battery EVs last year. Hybrids accounted for more than 4.2 million of the firm’s total global sales.

Honda Motor Co and Nissan Motor Co both also saw global vehicle sales stagnate or fall last year, underscoring the need for the pair to combine and arrest their sliding market shares.

Honda’s sales slipped 4.6 percent to 3.8 million units last year, as production dropped 11 percent to 3.7 million vehicles. Sales at smaller Japanese rival Nissan decreased 0.8 percent to 3.3 million for the 12 months, while output declined 8.7 percent to 3.1 million units.

Annual data released by each automaker yesterday reinforced why Honda is looking to build scale by absorbing Nissan, a deal that would create a new global heavyweight capable of competing at the highest levels of the world’s automobile industry — at least in theory.

Meanwhile, Nissan is eliminating a work shift at two US vehicle assembly plants and trimming its hourly staff via buyouts as it mulls a possible sale to Honda.

The Yokohama-based automaker said on Wednesday it will move to a single shift from mid-April at one production line in each of the factories, and seek an unspecified number of voluntary buyouts or early retirements.

“We’re responding to the needs of the market based on where we are today,” David Johnson, the company’s senior vice president in charge of US manufacturing and supply chain, said in an interview. He declined to say how many fewer cars Nissan expects to produce or the amount of the estimated cost-savings from the reductions.

In November last year, after a disastrous set of quarterly earnings, Nissan announced plans to cut 9,000 jobs and slash production capacity by 20 percent.

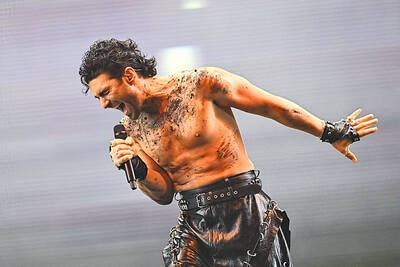

The Eurovision Song Contest has seen a surge in punter interest at the bookmakers, becoming a major betting event, experts said ahead of last night’s giant glamfest in Basel. “Eurovision has quietly become one of the biggest betting events of the year,” said Tomi Huttunen, senior manager of the Online Computer Finland (OCS) betting and casino platform. Betting sites have long been used to gauge which way voters might be leaning ahead of the world’s biggest televised live music event. However, bookmakers highlight a huge increase in engagement in recent years — and this year in particular. “We’ve already passed 2023’s total activity and

Nvidia Corp CEO Jensen Huang (黃仁勳) today announced that his company has selected "Beitou Shilin" in Taipei for its new Taiwan office, called Nvidia Constellation, putting an end to months of speculation. Industry sources have said that the tech giant has been eyeing the Beitou Shilin Science Park as the site of its new overseas headquarters, and speculated that the new headquarters would be built on two plots of land designated as "T17" and "T18," which span 3.89 hectares in the park. "I think it's time for us to reveal one of the largest products we've ever built," Huang said near the

China yesterday announced anti-dumping duties as high as 74.9 percent on imports of polyoxymethylene (POM) copolymers, a type of engineering plastic, from Taiwan, the US, the EU and Japan. The Chinese Ministry of Commerce’s findings conclude a probe launched in May last year, shortly after the US sharply increased tariffs on Chinese electric vehicles, computer chips and other imports. POM copolymers can partially replace metals such as copper and zinc, and have various applications, including in auto parts, electronics and medical equipment, the Chinese ministry has said. In January, it said initial investigations had determined that dumping was taking place, and implemented preliminary

Intel Corp yesterday reinforced its determination to strengthen its partnerships with Taiwan’s ecosystem partners including original-electronic-manufacturing (OEM) companies such as Hon Hai Precision Industry Co (鴻海精密) and chipmaker United Microelectronics Corp (UMC, 聯電). “Tonight marks a new beginning. We renew our new partnership with Taiwan ecosystem,” Intel new chief executive officer Tan Lip-bu (陳立武) said at a dinner with representatives from the company’s local partners, celebrating the 40th anniversary of the US chip giant’s presence in Taiwan. Tan took the reins at Intel six weeks ago aiming to reform the chipmaker and revive its past glory. This is the first time Tan