Taiwan Semiconductor Manufacturing Co (TSMC, 台積電) and other related companies would add ¥11.2 trillion (US$78.31 billion) to Japan’s chipmaking hot spot Kumamoto Prefecture over the next decade, a local bank’s analysis said.

Kyushu Financial Group, a lender based in Kumamoto’s capital, almost doubled its projection for the economic impact that the chip sector would bring to the region compared to its estimate a year earlier, a presentation on Thursday said.

The bank said that 171 firms had made new investments since November 2021, up from 90 in an earlier analysis.

Photo: EPA-EFE

TSMC’s Kumamoto location was once a sleepy farming area, but has undergone rapid growth as part of Japan’s chipmaking ambitions. TSMC, which opened its first plant there in February, is to start building a second by the end of the year and has shown intentions to construct a third.

The local economy is racing to keep up, with skyrocketing land prices and new infrastructure planned to deal with congestion from an influx of industry personnel. Kumamoto’s growth spurt has been supported by generous government subsidies, including grants totaling about ¥1.1 trillion for TSMC’s two plants to date.

Cooperation between Taiwan and Japan is increasingly crucial as supply chains become shorter and more regionally focused, a compound semiconductor company chairman said yesterday at a Taiwan-Japan exchange forum.

The global division of labor has been disrupted by the US-China trade and technology war, WIN Semiconductors Corp (穩懋) chairman Dennis Chen (陳進財) said.

“We have come to a point where there is no turning back, no matter who wins the presidency [in the next US presidential election],” he said during Semicon Taiwan.

However, localizing semiconductor manufacturing — widely regarded as a strategic resource — is easier said than done, as “every country has its specialty following 40 years of [globalized] supply chain development,” Chen said.

Taiwan and Japan are highly complementary in terms of their supply chain division of labor, he said.

“Taiwan is top in foundry and advanced packaging, and Japan leads in materials and equipment,” Chen said, citing Japan’s official numbers showing that it has 48 percent of the semiconductor material global market share and 31 percent of the equipment market share.

The two countries are also geographically and culturally close to each other, especially in terms of attitude toward work, he added.

On top of complementary dominant supply chain positions, Taiwan and Japan are on the side of democracy as “geopolitical changes have divided the world into two camps.”

In this democracy camp, more cooperation with the US, Europe, South Korea and Southeast Asia in forming a new supply chain is expected, he added.

Chen also said that customers in the US have urged his company to implement the “Taiwan plus one” strategy — manufacturing bases outside Taiwan.

In response, Chen said: “I believe Taiwan and Japan can take our cooperation to another level as we are natural partners in the industry.”

SETBACK: Apple’s India iPhone push has been disrupted after Foxconn recalled hundreds of Chinese engineers, amid Beijing’s attempts to curb tech transfers Apple Inc assembly partner Hon Hai Precision Industry Co (鴻海精密), also known internationally as Foxconn Technology Group (富士康科技集團), has recalled about 300 Chinese engineers from a factory in India, the latest setback for the iPhone maker’s push to rapidly expand in the country. The extraction of Chinese workers from the factory of Yuzhan Technology (India) Private Ltd, a Hon Hai component unit, in southern Tamil Nadu state, is the second such move in a few months. The company has started flying in Taiwanese engineers to replace staff leaving, people familiar with the matter said, asking not to be named, as the

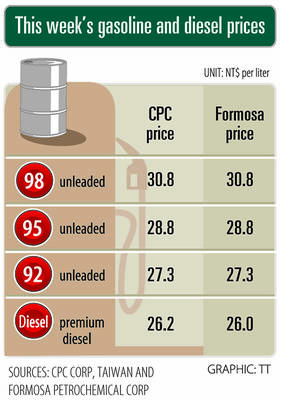

The prices of gasoline and diesel at domestic fuel stations are to rise NT$0.1 and NT$0.4 per liter this week respectively, after international crude oil prices rose last week, CPC Corp, Taiwan (台灣中油) and Formosa Petrochemical Corp (台塑石化) announced yesterday. Effective today, gasoline prices at CPC and Formosa stations are to rise to NT$27.3, NT$28.8 and NT$30.8 per liter for 92, 95 and 98-octane unleaded gasoline respectively, the companies said in separate statements. The price of premium diesel is to rise to NT$26.2 per liter at CPC stations and NT$26 at Formosa pumps, they said. The announcements came after international crude oil prices

SinoPac Financial Holdings Co (永豐金控) is weighing whether to add a life insurance business to its portfolio, but would tread cautiously after completing three acquisitions in quick succession, president Stanley Chu (朱士廷) said yesterday. “We are carefully considering whether life insurance should play a role in SinoPac’s business map,” Chu told reporters ahead of an earnings conference. “Our priority is to ensure the success of the deals we have already made, even though we are tracking some possible targets.” Local media have reported that Mercuries Life Insurance Co (三商美邦人壽), which is seeking buyers amid financial strains, has invited three financial

CAUTION: Right now, artificial intelligence runs on faith, not productivity and eventually, the risk of a bubble will emerge,’ TIER economist Gordon Sun said Taiwanese manufacturers turned more optimistic last month, ending a five-month streak of declining sentiment as concerns over US tariffs, currency volatility and China’s overcapacity began to ease, the Taiwan Institute of Economic Research (TIER) said yesterday. The manufacturing business confidence index rose 1.17 points from June to 86.8, its first rebound since February. TIER economist Gordon Sun (孫明德) attributed the uptick to fading trade uncertainties, a steadier New Taiwan dollar and reduced competitive pressure from Chinese producers. Taiwan’s semiconductor industry is unlikely to face significant damage from Washington’s ongoing probe into semiconductors, given the US’ reliance on Taiwanese chips to power artificial