Taiwan Semiconductor Manufacturing Co (TSMC, 台積電), the world’s largest contract chipmaker, on Monday issued a statement about the balanced life environment it provides its employees, in response to a Fortune article at the weekend in which several former and current employees in the US were quoted complaining about the company’s “brutal” corporate culture.

In the statement, TSMC said average work hours at the company have not exceeded 50 hours a week over the past two years with only a few exceptions, such as when the company introduces a new technology process or speeds up building a new plant. In such situations, a ceiling of 60 working hours a week is observed.

TSMC said it is the company’s unshirkable responsibility to provide employees with a balanced life environment, and with ongoing efforts to expand production worldwide the chipmaker is aware its top priority is to cultivate and manage cross-border talent.

Photo: Bloomberg

The company said it currently has a workforce of more than 70,000 employees worldwide.

The statement came after Fortune magazine cited messages posted by former and current TSMC employees in the US on an online job search Web site that they worked 12 hours a day, and weekend shifts were not uncommon.

“People ... slept in the office for a month straight,” a TSMC engineer was quoted as saying in a message posted to Glassdoor in August last year. “Twelve-hour days are standard, weekend shifts are common. I cannot stress ... how brutal the work-life balance is here.”

“TSMC is about obedience [and is] not ready for America,” another TSMC engineer was quoted as saying in a message posted in January.

Fortune said that TSMC’s US operations have earned a 27 percent approval rating on Glassdoor from 91 reviews, which means that less than one-third of reviewers would encourage others to work there. On the other hand, Intel Corp, one of TSMC’s major rivals, has an 85 percent approval rating, albeit from tens of thousands more reviews.

TSMC is spending US$40 billion to build two wafer fabs in Arizona, with one to use the 4-nanometer process and the other the more advanced 3-nanometer process. They are scheduled to start mass production next year and in 2026 respectively.

The 3-nanomater process is the latest technology TSMC uses for commercial production in Taiwan.

For its new production sites in Arizona, TSMC brought engineers hired in the US to Taiwan for training before they started their jobs. In addition, the company has sent Taiwanese engineers to Arizona in preparation for the opening of the new plants.

Due to its expansion globally, TSMC’s workforce continues to grow and has become diverse, the company said, adding that it listens to a wide range of opinions from its employees through established communications channels.

TSMC said it has established a comprehensive recruitment and training package, while trying its best to retain employees and place them in the right positions.

In addition to 13 site labor-management meetings, TSMC has also set up 10 new Silicon Garden Meetings, labor-management meetings by function/division and launched a dedicated opinion collection system in the fourth quarter of last year to enhance communications and forge better ties with its employees, the company said.

The Silicon Garden Meetings allow employees to voice their opinions via employee representatives during quarterly meetings and the online system can also be used to express their opinions at any time, TSMC said.

Through these communication channels, employees are able to give their opinions using their real names or anonymously, and responses are provided in a timely manner, the company said.

DIVIDED VIEWS: Although the Fed agreed on holding rates steady, some officials see no rate cuts for this year, while 10 policymakers foresee two or more cuts There are a lot of unknowns about the outlook for the economy and interest rates, but US Federal Reserve Chair Jerome Powell signaled at least one thing seems certain: Higher prices are coming. Fed policymakers voted unanimously to hold interest rates steady at a range of 4.25 percent to 4.50 percent for a fourth straight meeting on Wednesday, as they await clarity on whether tariffs would leave a one-time or more lasting mark on inflation. Powell said it is still unclear how much of the bill would fall on the shoulders of consumers, but he expects to learn more about tariffs

NOT JUSTIFIED: The bank’s governor said there would only be a rate cut if inflation falls below 1.5% and economic conditions deteriorate, which have not been detected The central bank yesterday kept its key interest rates unchanged for a fifth consecutive quarter, aligning with market expectations, while slightly lowering its inflation outlook amid signs of cooling price pressures. The move came after the US Federal Reserve held rates steady overnight, despite pressure from US President Donald Trump to cut borrowing costs. Central bank board members unanimously voted to maintain the discount rate at 2 percent, the secured loan rate at 2.375 percent and the overnight lending rate at 4.25 percent. “We consider the policy decision appropriate, although it suggests tightening leaning after factoring in slackening inflation and stable GDP growth,”

Greek tourism student Katerina quit within a month of starting work at a five-star hotel in Halkidiki, one of the country’s top destinations, because she said conditions were so dire. Beyond the bad pay, the 22-year-old said that her working and living conditions were “miserable and unacceptable.” Millions holiday in Greece every year, but its vital tourism industry is finding it harder and harder to recruit Greeks to look after them. “I was asked to work in any department of the hotel where there was a need, from service to cleaning,” said Katerina, a tourism and marketing student, who would

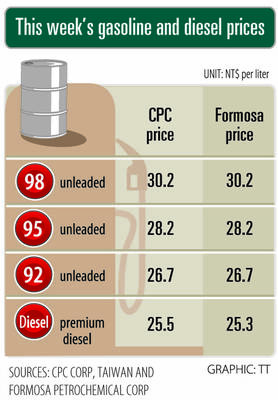

i Gasoline and diesel prices at fuel stations are this week to rise NT$0.1 per liter, as tensions in the Middle East pushed crude oil prices higher last week, CPC Corp, Taiwan (台灣中油) and Formosa Petrochemical Corp (台塑石化) said yesterday. International crude oil prices last week rose for the third consecutive week due to an escalating conflict between Israel and Iran, as the market is concerned that the situation in the Middle East might affect crude oil supply, CPC and Formosa said in separate statements. Front-month Brent crude oil futures — the international oil benchmark — rose 3.75 percent to settle at US$77.01