Taiwan Semiconductor Manufacturing Co (TSMC, 台積電) yesterday expressed confidence that its 2-nanometer process technology would be the most advanced foundry technology in the world when it is introduced in 2025, shrugging off Samsung Electronics Co’s plans to overtake its technology leadership position.

“Today, the 3-nanometer technology we offer is the world’s most advanced technology. When we launch our 2-nanometer technology in 2025, there is no doubt in my mind that it will be the most advanced semiconductor technology in the world,” senior vice president of business development Kevin Zhang (張曉強) said in response to a reporter’s question about Samsung’s plans.

Two enhanced versions, dubbed N2P and N2X, would be launched in 2026, TSMC said during an annual technology symposium in Hsinchu.

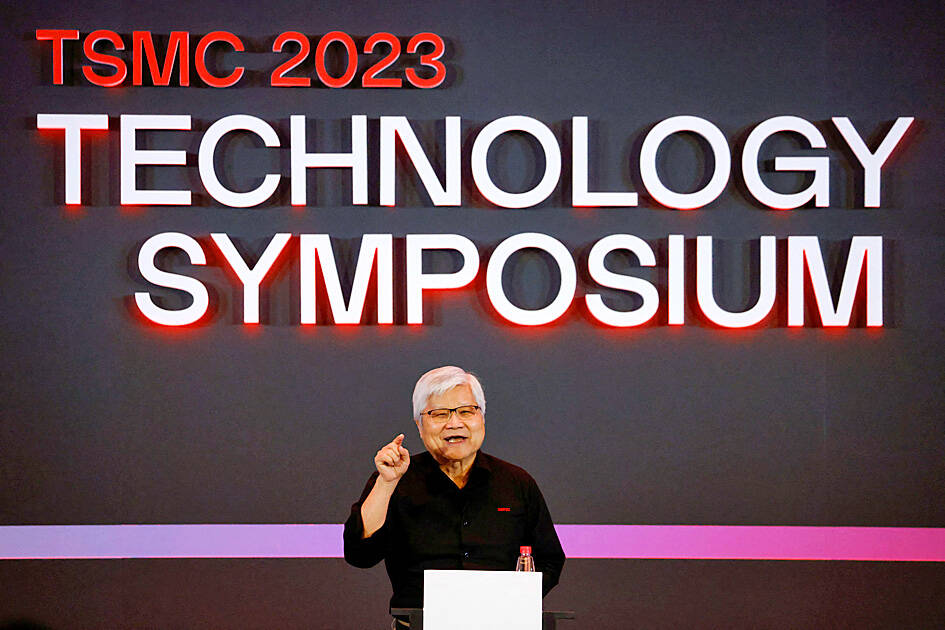

Photo: Carlos Garcia Rawlins, Reuters

Samsung aims to surpass its bigger foundry rival TSMC to become the industry leader within five years, the Korea Economic Daily reported on Thursday last week.

The South Korean technology giant expects to get ahead of TSMC with its 2-nanometer processing node, Samsung’s head of semiconductor business Kyun Kye-hyun said during a lecture.

Samsung plans to mass produce 2-nanometer chips in 2025 as well. Its 2-nanometer technology would be based on the get-all-around structure, while TSMC adopts a nano sheet transistor structure, which it believes is a more mature technology, with less power consumption and greater performance.

In preparation for the mass production of its 2-nanometer chips, TSMC, the world’s biggest contract chipmaker, is constructing a new factory in Hsinchu and would break ground for another one in Taichung next year.

The 2-nanometer chips would be used in smartphones and high-performance-computing (HPC) devices, the chipmaker said.

Commenting on market concern about TSMC’s 3-nanometer process, Zhang said the technology’s yield would soon catch up with that of its 5-nanometer process.

“We have strong confidence in our 3-nanometer processor, which is stable,” Zhang said. “We are seeing 1.5 to two times the number of customers engaging in our 3-nanometer [technology] compared with 5-nanometer during the initial period.”

Its automaker customers are participating in a program to upgrade to a new version of 3-nanometer auto chips, called Auto Early technology, Zhang said.

The new technology would allow customers to start designing chips two to three years earlier than before and to shorten their time to market, he said.

TSMC last month said that it was unable to meet customers’ demand for 3-nanometer chips.

Most of its smartphone and HPC customers are migrating to the 3-nanometer technology, Zhang said.

TSMC chief executive officer C.C. Wei (魏哲家) yesterday in Hsinchu said that TSMC is a more reliable and trustworthy partner, as it does not compete with its customers.

“Our two competitors, one from South Korea and one based in California, develop their [own] products,” Wei said.

“TSMC does not develop [its own] products. We do not compete with you,” he told customers.

Samsung and Intel Corp are competing with TSMC to vie for a bigger market share and technology leadership.

KEEPING UP: The acquisition of a cleanroom in Taiwan would enable Micron to increase production in a market where demand continues to outpace supply, a Micron official said Micron Technology Inc has signed a letter of intent to buy a fabrication site in Taiwan from Powerchip Semiconductor Manufacturing Corp (力積電) for US$1.8 billion to expand its production of memory chips. Micron would take control of the P5 site in Miaoli County’s Tongluo Township (銅鑼) and plans to ramp up DRAM production in phases after the transaction closes in the second quarter, the company said in a statement on Saturday. The acquisition includes an existing 12 inch fab cleanroom of 27,871m2 and would further position Micron to address growing global demand for memory solutions, the company said. Micron expects the transaction to

Vincent Wei led fellow Singaporean farmers around an empty Malaysian plot, laying out plans for a greenhouse and rows of leafy vegetables. What he pitched was not just space for crops, but a lifeline for growers struggling to make ends meet in a city-state with high prices and little vacant land. The future agriculture hub is part of a joint special economic zone launched last year by the two neighbors, expected to cost US$123 million and produce 10,000 tonnes of fresh produce annually. It is attracting Singaporean farmers with promises of cheaper land, labor and energy just over the border.

US actor Matthew McConaughey has filed recordings of his image and voice with US patent authorities to protect them from unauthorized usage by artificial intelligence (AI) platforms, a representative said earlier this week. Several video clips and audio recordings were registered by the commercial arm of the Just Keep Livin’ Foundation, a non-profit created by the Oscar-winning actor and his wife, Camila, according to the US Patent and Trademark Office database. Many artists are increasingly concerned about the uncontrolled use of their image via generative AI since the rollout of ChatGPT and other AI-powered tools. Several US states have adopted

A proposed billionaires’ tax in California has ignited a political uproar in Silicon Valley, with tech titans threatening to leave the state while California Governor Gavin Newsom of the Democratic Party maneuvers to defeat a levy that he fears would lead to an exodus of wealth. A technology mecca, California has more billionaires than any other US state — a few hundred, by some estimates. About half its personal income tax revenue, a financial backbone in the nearly US$350 billion budget, comes from the top 1 percent of earners. A large healthcare union is attempting to place a proposal before