Taiwan Semiconductor Manufacturing Co (TSMC, 台積電) yesterday said that three new plants in Kaohsiung, Japan and the US would start production in 2024, as it accelerates its capacity expansion to cope with growing semiconductor demand.

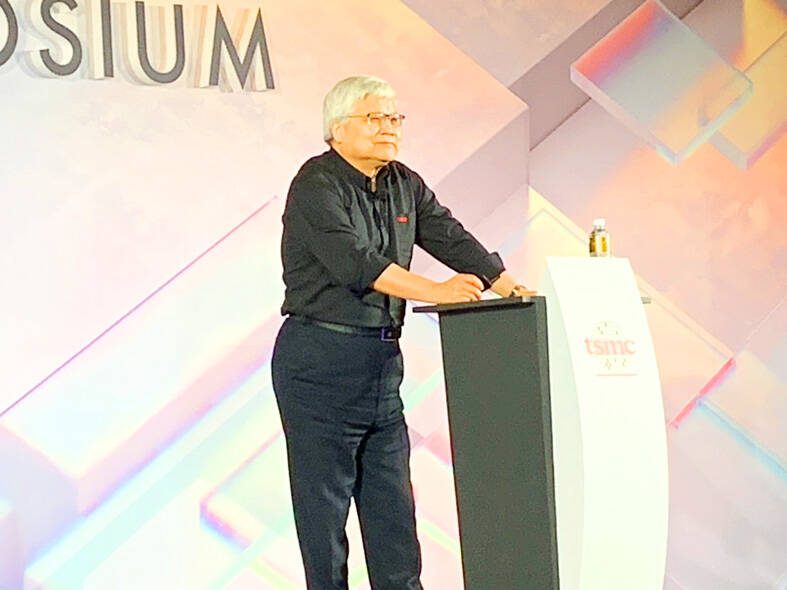

Apart from the two fabs that are under construction in Arizona and in Kumamoto, Japan, the world’s biggest contract chipmaker plans to start building a new fab in Kaohsiung in the second half of this year, TSMC vice president Y.L. Wang (王英郎) said at the firm’s annual technology symposium in Hsinchu.

The Kaohsiung fab, dubbed Fab 22, would produce 7-nanometer and 28-nanometer chips once it begins operations in 2024, Wang said.

Photo: Grace Hung, Taipei Times

The Arizona fab is to make 5-nanometer chips and the Kumamoto fab is to produce chips using specialty process technologies, he said.

To satisfy customer demand, TSMC is not only increasing leading-edge technology capacity, but also mature-node technologies, Wang said.

TSMC expects its advanced technology capacity to expand at a compound annual growth rate of 70 percent from 2018 to this year, thanks to robust demand for chips used in smartphones and high-performance computing devices such as servers, Wang said.

.Photo: Grace Hung, Taipei Times

This year alone, the company’s 5-nanometer chip capacity would more than quadruple from two years earlier, he said.

On top of that, TSMC plans to produce 3-nanometer chips in the second half of this year, Wang said, adding that 3-nanometer capacity is expected to increase rapidly at its Tainan fabs to cope with customer demand.

Because of substantial customer demand for 3-nanometer chips, the company’s engineering capacity is tight, TSMC chief executive officer C.C. Wei (魏哲家) said at the symposium.

The chipmaker plans to produce next-generation 2-nanometer chips at new factories in Hsinchu, Wang said.

TSMC is also stepping up its efforts to expand specialty technology capacity to meet rising demand for image sensors and radio frequency chips, Wang said.

Capital investment for specialty technologies would grow about 4.5-fold compared with the average outlay over the past three years, he said.

That would boost the capacity contribution from specialty technologies to about 63 percent of total wafer capacity this year, compared with 45 percent in 2018, he said.

The chipmaker has been expanding capacity faster in the past few years with an average of six factories built each year from 2018 to this year, compared with two factories from 2017 to 2019, Wang said.

However, TSMC said that chip manufacturing costs are rising rapidly, as China, Japan, the EU and the US are pushing to localize chip manufacturing to boost the resilience of their chip supply amid geopolitical tensions.

It is going to be costly if manufacturers reverse the globalization that has created economic benefits, Wei said.

In addition, TSMC has been making chips using specialty technologies at existing factories without the burden of depreciation and amortization costs, he said.

To make enough specialty technology chips to meet rising demand for vehicle chips and other applications, TSMC is building new factories, but would charge more for the chips due to depreciation and amortization costs, as well as the high cost of equipment tools, he said.

NEW IDENTITY: Known for its software, India has expanded into hardware, with its semiconductor industry growing from US$38bn in 2023 to US$45bn to US$50bn India on Saturday inaugurated its first semiconductor assembly and test facility, a milestone in the government’s push to reduce dependence on foreign chipmakers and stake a claim in a sector dominated by China. Indian Prime Minister Narendra Modi opened US firm Micron Technology Inc’s semiconductor assembly, test and packaging unit in his home state of Gujarat, hailing the “dawn of a new era” for India’s technology ambitions. “When young Indians look back in the future, they will see this decade as the turning point in our tech future,” Modi told the event, which was broadcast on his YouTube channel. The plant would convert

Nanya Technology Corp (南亞科技) yesterday said the DRAM supply crunch could extend through 2028, as the artificial intelligence (AI) boom has led the world’s major memory makers to dramatically reduce production of standard DRAM and allocate a significant portion of their capacity for high-bandwidth memory (HBM) chips. The most severe supply constraints would stretch to the first half of next year due to “very limited” increases in new DRAM capacity worldwide, Nanya Technology president Lee Pei-ing (李培瑛) told a news briefing. The company plans to increase monthly 12-inch wafer capacity to 20,000 in the first half of 2028 after a

Property transactions in the nation’s six special municipalities plunged last month, as a lengthy Lunar New Year holiday combined with ongoing credit tightening dampened housing market activity, data compiled by local land administration offices released on Monday showed. The six cities recorded a total of 10,480 property transfers last month, down 42.5 percent from January and marking the second-lowest monthly level on record, the data showed. “The sharp drop largely reflected seasonal factors and tighter credit conditions,” Evertrust Rehouse Co (永慶房屋) deputy research manager Chen Chin-ping (陳金萍) said. The nine-day Lunar New Year holiday fell in February this year, reducing

New vehicle sales in Taiwan plunged about 37 percent sequentially last month as the long Lunar New Year holiday and 228 Peace Memorial Day holiday cut short the number of working days, along with the lingering uncertainty over import tax cuts on US vehicles, market researcher U-Car said in a report yesterday. New car sales last month totaled 22,043, slumping from 35,073 units in January and down 19.89 percent from 37,515 in February last year, U-Car data showed. Sales of imported luxury cars, led by Mercedes-Benz, plummeted about 45 percent to 3,109 units last month from 5,663 units in the previous month,