Power rationing and forced cuts to factory production in China are widening amid electricity supply issues and a push to enforce environmental regulations.

The curbs have expanded to more than 10 provinces, including economic powerhouses Jiangsu, Zhejiang and Guangdong, the 21st Century Business Herald reported yesterday. Several companies have reported the impacts of power curbs in filings on China’s stock exchanges.

Local governments are ordering power cuts as they try to hit targets for reducing energy and emissions intensity. The country’s top economic planner last month flagged nine provinces for increasing intensity this year amid a strong economic rebound from the COVID-19 pandemic.

Meanwhile, record high coal prices are making many power plants unprofitable, creating supply gaps in some provinces, the Business Herald reported. If those gaps expand, the effect could be worse than power curtailments that hit parts of the country during the summer.

In Zhejiang, about 160 energy-intensive companies in the textile, dyeing and chemical fiber industries have been ordered to halt production to meet energy consumption targets, the Caixin media group reported.

Emergency power cuts were also ordered across 14 cities in Liaoning Province after the grid suffered supply shortfalls, a notice on the local grid operator’s social media said on Thursday.

“Power suppliers will spare no effort to keep providing electricity to residents, hospitals, schools, radio, TV, telecommunications, transportation hubs and other important users,” the notice said.

Yunnan province is canceling price discounts for aluminum smelters. The discounts made power costs about 16 to 22 percent cheaper than the industry average, a separate Caixin report said. Yunnan Aluminum Co (雲南鋁業公司)last week said its production through the rest of the year is to be significantly cut due to the controls.

The CSI 300 Utilities subgauge is up 19 percent this month, hitting the highest since late 2015 this week amid tight supply. Huaneng Power International Inc (華能國際) and GD Power Development Co (國電電力發展公司) are up at least 40 percent this month, leading on the subgauge, while smaller power stocks such as Zhongmin Energy Co (中閩能源) and Shanghai Electric Power Co (上海電力) have added at least 70 percent.

The power curbs are also affecting agriculture, forcing the shutdown of several plants that crush soybeans into oils used in salad dressings and margarine, AgriCensus reported.

Taiwan’s exports soared 56 percent year-on-year to an all-time high of US$64.05 billion last month, propelled by surging global demand for artificial intelligence (AI), high-performance computing and cloud service infrastructure, the Ministry of Finance said yesterday. Department of Statistics Director-General Beatrice Tsai (蔡美娜) called the figure an unexpected upside surprise, citing a wave of technology orders from overseas customers alongside the usual year-end shopping season for technology products. Growth is likely to remain strong this month, she said, projecting a 40 percent to 45 percent expansion on an annual basis. The outperformance could prompt the Directorate-General of Budget, Accounting and

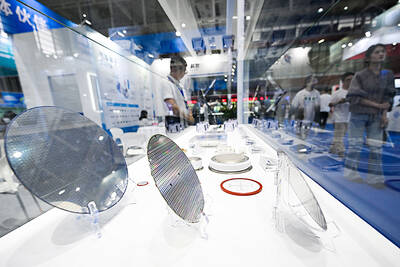

Two Chinese chipmakers are attracting strong retail investor demand, buoyed by industry peer Moore Threads Technology Co’s (摩爾線程) stellar debut. The retail portion of MetaX Integrated Circuits (Shanghai) Co’s (上海沐曦) upcoming initial public offering (IPO) was 2,986 times oversubscribed on Friday, according to a filing. Meanwhile, Beijing Onmicro Electronics Co (北京昂瑞微), which makes radio frequency chips, was 2,899 times oversubscribed on Friday, its filing showed. The bids coincided with Moore Threads’ trading debut, which surged 425 percent on Friday after raising 8 billion yuan (US$1.13 billion) on bets that the company could emerge as a viable local competitor to Nvidia

BARRIERS: Gudeng’s chairman said it was unlikely that the US could replicate Taiwan’s science parks in Arizona, given its strict immigration policies and cultural differences Gudeng Precision Industrial Co (家登), which supplies wafer pods to the world’s major semiconductor firms, yesterday said it is in no rush to set up production in the US due to high costs. The company supplies its customers through a warehouse in Arizona jointly operated by TSS Holdings Ltd (德鑫控股), a joint holding of Gudeng and 17 Taiwanese firms in the semiconductor supply chain, including specialty plastic compounds producer Nytex Composites Co (耐特) and automated material handling system supplier Symtek Automation Asia Co (迅得). While the company has long been exploring the feasibility of setting up production in the US to address

OPTION: Uber said it could provide higher pay for batch trips, if incentives for batching is not removed entirely, as the latter would force it to pass on the costs to consumers Uber Technologies Inc yesterday warned that proposed restrictions on batching orders and minimum wages could prompt a NT$20 delivery fee increase in Taiwan, as lower efficiency would drive up costs. Uber CEO Dara Khosrowshahi made the remarks yesterday during his visit to Taiwan. He is on a multileg trip to the region, which includes stops in South Korea and Japan. His visit coincided the release last month of the Ministry of Labor’s draft bill on the delivery sector, which aims to safeguard delivery workers’ rights and improve their welfare. The ministry set the minimum pay for local food delivery drivers at