Nissan Motor Co on Tuesday said that its factory in Smyrna, Tennessee, would close for two weeks starting on Monday due to chip shortages brought on by a COVID-19 outbreak in Malaysia.

The shutdown is among the longest at any US auto plant of this size since the semiconductor shortage, which has hobbled vehicle production worldwide, started late last year.

Nissan said that it ran short of chips due to a virus outbreak at a chip factory in Malaysia.

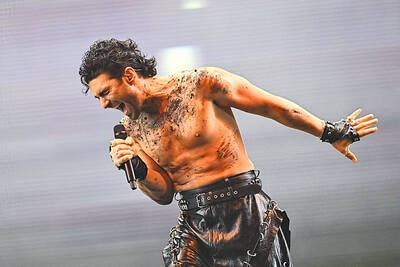

Photo: Bloomberg

It expects production to resume on Aug. 30.

The 560,000m2 Tennessee factory employs 6,700 people and makes six Nissan models, including the Rogue small sports utility vehicle (SUV), the company’s top-selling US vehicle.

Analysts said that the temporary closure is a sign that the semiconductor shortage might not be coming to an end late this year as many industry executives had hoped.

Automakers have tried to conserve chips for plants that make their US top sellers, largely SUVs and pickup trucks.

However, pickup truck plants have been shut down sporadically as well, including three General Motors Co factories this week.

Sam Abuelsamid, an analyst at Guidehouse Research Principal, said that the Smyrna plant is crucial for Nissan, adding that the shutdown is a sign that the end of the semiconductor shortage might not be in sight.

“It’s looking like it’s going to stretch at least into the new year,” he said.

With continuing COVID-19 outbreaks across the semiconductor supply chain in Asia and other regions, supply problems might last even longer than that, Abuelsamid said.

The chip shortage is starting to improve, but the Delta variant of SARS-CoV-2 is starting to cause problems at factories in the semiconductor supply chain, making matters worse, IHS Markit senior principal analyst Phil Amsrud said.

Large chip foundries in Taiwan and elsewhere in Asia take large silicon wafers and turn them into multiple smaller integrated circuits. They are then shipped to “back- end” manufacturers in Malaysia, where they are cut into chips that are used in automotive control computers.

However, outbreaks among workers in those factories, and in the shipping business, are affecting supplies again, as evidenced by the Nissan shutdown, Amsrud said.

Also, chips that automakers are getting now might not be the right ones for products they want to build in the future, he said.

In addition, many countries that do the back-end work like Malaysia have low COVID-19 vaccination rates, Amsrud said.

“It looks to me like we’re just set up for Delta getting a foothold in all of these locations,” he said. “I think Delta is going to still cause us all sorts of problems.”

The Eurovision Song Contest has seen a surge in punter interest at the bookmakers, becoming a major betting event, experts said ahead of last night’s giant glamfest in Basel. “Eurovision has quietly become one of the biggest betting events of the year,” said Tomi Huttunen, senior manager of the Online Computer Finland (OCS) betting and casino platform. Betting sites have long been used to gauge which way voters might be leaning ahead of the world’s biggest televised live music event. However, bookmakers highlight a huge increase in engagement in recent years — and this year in particular. “We’ve already passed 2023’s total activity and

Nvidia Corp CEO Jensen Huang (黃仁勳) today announced that his company has selected "Beitou Shilin" in Taipei for its new Taiwan office, called Nvidia Constellation, putting an end to months of speculation. Industry sources have said that the tech giant has been eyeing the Beitou Shilin Science Park as the site of its new overseas headquarters, and speculated that the new headquarters would be built on two plots of land designated as "T17" and "T18," which span 3.89 hectares in the park. "I think it's time for us to reveal one of the largest products we've ever built," Huang said near the

China yesterday announced anti-dumping duties as high as 74.9 percent on imports of polyoxymethylene (POM) copolymers, a type of engineering plastic, from Taiwan, the US, the EU and Japan. The Chinese Ministry of Commerce’s findings conclude a probe launched in May last year, shortly after the US sharply increased tariffs on Chinese electric vehicles, computer chips and other imports. POM copolymers can partially replace metals such as copper and zinc, and have various applications, including in auto parts, electronics and medical equipment, the Chinese ministry has said. In January, it said initial investigations had determined that dumping was taking place, and implemented preliminary

Intel Corp yesterday reinforced its determination to strengthen its partnerships with Taiwan’s ecosystem partners including original-electronic-manufacturing (OEM) companies such as Hon Hai Precision Industry Co (鴻海精密) and chipmaker United Microelectronics Corp (UMC, 聯電). “Tonight marks a new beginning. We renew our new partnership with Taiwan ecosystem,” Intel new chief executive officer Tan Lip-bu (陳立武) said at a dinner with representatives from the company’s local partners, celebrating the 40th anniversary of the US chip giant’s presence in Taiwan. Tan took the reins at Intel six weeks ago aiming to reform the chipmaker and revive its past glory. This is the first time Tan