Taiwan Semiconductor Manufacturing Co (TSMC, 台積電) yesterday unveiled the layout of its new fab in Arizona and reiterated its determination to ramp up advanced 5-nanometer chip production in 2024.

The company said that construction of Fab 21, in which it would invest US$10 billion to US$12 billion, has begun on a 445 hectare plot in Phoenix.

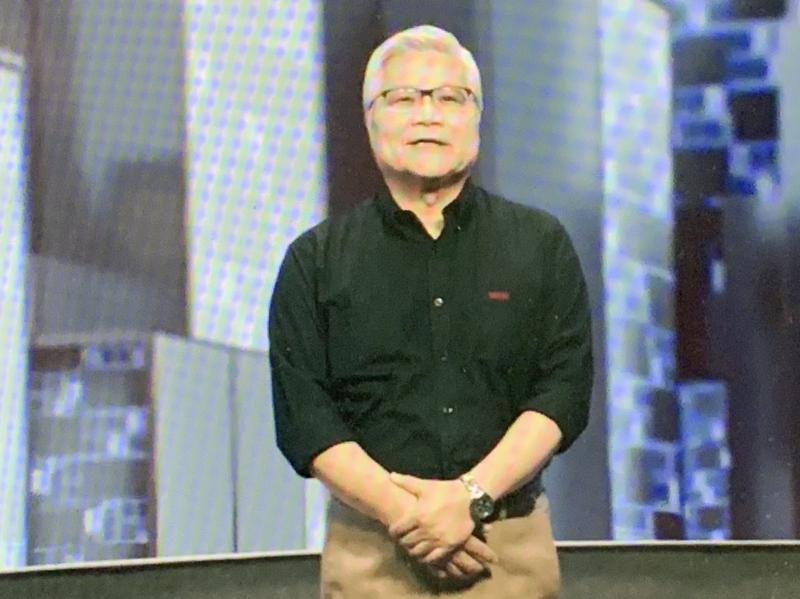

“As we expect demand for 5-nanometer [chips] will be strong and sustainable in the long term, we have made the Arizona fab, Fab 21, one of the 5-nanometer manufacturing sites,” TSMC chief executive officer C.C. Wei (魏哲家) told the company’s annual technology symposium.

Photo: Grace Hung, Taipei Times

The chipmaker has shipped more than 500,000 5-nanometer chips from its Fab 18 in Tainan since the technology became available last year, thanks to robust customer demand for smartphones, 5G applications, artificial-intelligence (AI) applications, networking devices and high-performance computing devices, Wei said.

The first phase of the Arizona fab would have an installed capacity of 20,000 wafers a month, TSMC said.

In January, the chipmaker said that further expansion would depend on market conditions and US government support.

TSMC yesterday introduced the technology for its new N5A process to produce 5-nanometer chips for automotive applications such as AI-enabled driver assistance and the digitization of vehicle cockpits.

Production using the N5A process is scheduled to be available in the third quarter of next year, Wei said.

The chipmaker said that its 3-nanometer technology would be the world’s most advanced technology when volume production begins in the second half of next year.

Its fabs in Tainan would be its major manufacturing sites for 3-nanometer chips, TSMC said.

To expedite mass production of 3-nanometer and 2-nanometer chips, TSMC is transforming its 2-nanometer research centers in Hsinchu into sites for initial production of new-generation chips, it said.

TSMC has been boosted capacity to catch up with customers' rising demand,expecting that its advanced technology capacity would expand at a compound annual rate of 30 percent from 2018 to this year.

Among advanced technologies,7-nanometer chip capacity would have increased fourfold until this year since 2018, TSMC senior vice president Y.P. Chin (秦永沛) told the symposium.

Five-nanometer chip capacity would quadruple until 2023 from last year’s level, he said.

The company is also expanding its advanced chip testing and packaging capacity to cope with growing demand, Chin said.

TSMC is building its fifth fab in Miaoli County’s Jhunan Township (竹南), which would offer the most advanced 3D packaging technology of system-on-integrated-chip in the second half of next year, he said.

South Korea’s equity benchmark yesterday crossed a new milestone just a month after surpassing the once-unthinkable 5,000 mark as surging global memory demand powers the country’s biggest chipmakers. The KOSPI advanced as much as 2.6 percent to a record 6,123, with Samsung Electronics Co and SK Hynix Inc each gaining more than 2 percent. With the benchmark now up 45 percent this year, South Korea’s stock market capitalization has also moved past France’s, following last month’s overtaking of Germany’s. Long overlooked by foreign funds, despite being undervalued, South Korean stocks have now emerged as clear winners in the global market. The so-called “artificial intelligence

NEW IDENTITY: Known for its software, India has expanded into hardware, with its semiconductor industry growing from US$38bn in 2023 to US$45bn to US$50bn India on Saturday inaugurated its first semiconductor assembly and test facility, a milestone in the government’s push to reduce dependence on foreign chipmakers and stake a claim in a sector dominated by China. Indian Prime Minister Narendra Modi opened US firm Micron Technology Inc’s semiconductor assembly, test and packaging unit in his home state of Gujarat, hailing the “dawn of a new era” for India’s technology ambitions. “When young Indians look back in the future, they will see this decade as the turning point in our tech future,” Modi told the event, which was broadcast on his YouTube channel. The plant would convert

‘SEISMIC SHIFT’: The researcher forecast there would be about 1.1 billion mobile shipments this year, down from 1.26 billion the prior year and erasing years of gains The global smartphone market is expected to contract 12.9 percent this year due to the unprecedented memorychip shortage, marking “a crisis like no other,” researcher International Data Corp (IDC) said. The new forecast, a dramatic revision down from earlier estimates, gives the latest accounting of the ongoing memory crunch that is affecting every corner of the electronics industry. The demand for advanced memory to power artificial intelligence (AI) tasks has drained global supply until well into next year and jeopardizes the business model of many smartphone makers. IDC forecast about 1.1 billion mobile shipments this year, down from 1.26 billion the prior

People stand in a Pokemon store in Tokyo on Thursday. One of the world highest-grossing franchises is celebrated its 30th anniversary yesterday.