Formosa Plastics Group (FPG, 台塑集團) yesterday announced that it is to form a joint venture in Taiwan with Japanese chemicals company Tokuyama Corp to manufacture and sell high-purity isopropyl alcohol (IPA) to the electronics industry.

FPG chairman and president Jason Lin (林健男) is to be chairman of the new venture, which is to be called Formosa Tokuyama Advanced Chemicals Co, while Tokuyama Corp general manager Haruyoshi Honda is to be general manager.

FPG and Tokuyama Corp are each to hold a 50 percent stake in the new company. The companies have invested NT$1 billion (US$34.16 million) of capital into the new venture.

Tokuyama Corp said in a statement that the company’s board of directors approved the joint venture at a meeting yesterday. FPG confirmed the formation of the joint venture in a filing to the Taiwan Stock Exchange.

“Due to the advances made in 5G, IoT [Internet of Things], AI [artificial intelligence] and other technologies, the semiconductor market is expected to continue expanding over the medium and long term, and accordingly demand for high-purity IPA is forecast to gradually increase,” Tokuyama said in the statement.

The joint venture would allow the company to “immediately respond” to the needs of its customers in Taiwan, the Japanese firm said.

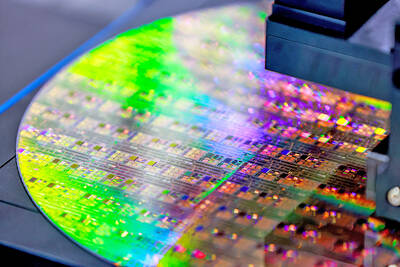

Tokuyama’s IPA is made for the electronics industry using a “proprietary method” to achieve a “purity level of over 99.99 percent,” according to the company’s Web site.

“This product is ideal for cleaning and drying electronic devices, including semiconductors and glass substrates,” the Web site says.

Tokuyama is a supplier of high-purity chemicals to a number of leading Taiwanese semiconductor companies, including Taiwan Semiconductor Manufacturing Co (台積電), United Microelectronics Corp (聯電) and Winbond Electronics Corp (華邦電子), according to a Ministry of Economic Affairs statement last year.

Tokuyama established its first factory in Taiwan in Hsinchu in 1996, followed by a NT$600 million plant in Yunlin County that was completed last year as a part of the government’s Invest in Taiwan initiative, the statement said.

The plant for the joint venture is to be on a 1.6 hectare plot in Kaohsiung, with construction scheduled to be completed by September next year and production beginning by December, the Central News Agency reported yesterday, citing FPG and Tokuyama sources.

The plant is expected to produce 30,000 tonnes of high-purity IPA per year, made from propylene supplied by FPG, the report said.

Taiwan’s rapidly aging population is fueling a sharp increase in homes occupied solely by elderly people, a trend that is reshaping the nation’s housing market and social fabric, real-estate brokers said yesterday. About 850,000 residences were occupied by elderly people in the first quarter, including 655,000 that housed only one resident, the Ministry of the Interior said. The figures have nearly doubled from a decade earlier, Great Home Realty Co (大家房屋) said, as people aged 65 and older now make up 20.8 percent of the population. “The so-called silver tsunami represents more than just a demographic shift — it could fundamentally redefine the

The US government on Wednesday sanctioned more than two dozen companies in China, Turkey and the United Arab Emirates, including offshoots of a US chip firm, accusing the businesses of providing illicit support to Iran’s military or proxies. The US Department of Commerce included two subsidiaries of US-based chip distributor Arrow Electronics Inc (艾睿電子) on its so-called entity list published on the federal register for facilitating purchases by Iran’s proxies of US tech. Arrow spokesman John Hourigan said that the subsidiaries have been operating in full compliance with US export control regulations and his company is discussing with the US Bureau of

Businesses across the global semiconductor supply chain are bracing themselves for disruptions from an escalating trade war, after China imposed curbs on rare earth mineral exports and the US responded with additional tariffs and restrictions on software sales to the Asian nation. China’s restrictions, the most targeted move yet to limit supplies of rare earth materials, represent the first major attempt by Beijing to exercise long-arm jurisdiction over foreign companies to target the semiconductor industry, threatening to stall the chips powering the artificial intelligence (AI) boom. They prompted US President Donald Trump on Friday to announce that he would impose an additional

Pegatron Corp (和碩), a key assembler of Apple Inc’s iPhones, on Thursday reported a 12.3 percent year-on-year decline in revenue for last quarter to NT$257.86 billion (US$8.44 billion), but it expects revenue to improve in the second half on traditional holiday demand. The fourth quarter is usually the peak season for its communications products, a company official said on condition of anonymity. As Apple released its new iPhone 17 series early last month, sales in the communications segment rose sequentially last month, the official said. Shipments to Apple have been stable and in line with earlier expectations, they said. Pegatron shipped 2.4 million notebook