Travel restrictions to China due to the COVID-19 outbreak have come just as Apple Inc’s engineers usually travel to Asia to perfect the production of new iPhones, former employees and supply chain experts told reporters.

High-volume manufacturing is not scheduled until summer, but the first few months of the year are when Apple irons out assembly processes with partners, such as Hon Hai Precision Industry Co (鴻海精密), known as Foxconn Technology Group (富士康科技集團) outside of Taiwan, two former Apple employees said.

“They probably have one assembly line they’re trying things out on,” said one of the former employees, who asked not to be named discussing production matters.

“Are Apple’s engineers with the Foxconn engineers? If they are, they’re probably making progress, but if they’re not, if they’re quarantined, that could be bad,” they said.

While Apple uses other contract manufacturers, such as Wistron Corp (緯創), to make some iPhones, Hon Hai tends to handle the introduction of new models because its capabilities are the most advanced, supply chain experts said.

Hon Hai, the world’s largest contract electronics maker, delayed reopening key iPhone factories in Shenzhen and Zhengzhou after the Lunar New Year holiday, but hopes to resume half of its Chinese production by the end of this month.

Senior Hon Hai officials who have been working remotely from Taipei since the holiday have not yet returned to China on a large scale, a person with knowledge of the matter told reporters, speaking of company officials generally.

For new iPhone models, the transition from prototype to the assembly of millions of units starts in earnest when the holiday ends, people familiar with the process said.

At that point, Apple has tested numerous prototypes and is in the late stages of what is called engineering validation, in which Hon Hai workers assemble small numbers of devices while engineers from both firms troubleshoot.

If delays occur at this stage, it would eat into the time Apple needs to finalize orders for chips and other parts, almost all of which are custom-made.

Due to the huge volumes needed, “they can’t wait to make component selections,” said Ron Keith, founder of Supply Chain Resources Group, which works with electronics makers such as Alphabet Inc’s Nest.

In March and April, Apple engineers typically work with Hon Hai counterparts to set up new assembly lines and do trial runs, before making final adjustments in April and May.

The aim is to have production lines up and running in June so others can be added progressively to ramp up output.

“It’s very complicated. There are so many variables in the environment, including small factors such as air pollution,” one of the people familiar with the process said.

Anna-Katrina Shedletsky, a former Apple engineer and founder of Instrumental Inc, a start-up focused on factory automation based in Mountain View, California, said that on-the-ground engineering collaboration was critical for new products.

“You can fly those engineers somewhere else, but there’s knowledge about how you make a product in that environment. It’s not that it can’t be taught, but it’s a hard thing to move,” she said.

While supply chain experts and industry insiders have said that Apple still has time to keep its annual iPhone schedule on track, travel restrictions have left it in a tough spot.

“There is no face-to-face work being done,” an executive at a semiconductor firm that supplies smartphone companies and works with teams in China said, speaking generally about mobile phone production cycles.

“And the word is that’s probably not going to change for another month at best. You’re really talking about two lost months, which in the consumer electronics cycle is huge,” they added.

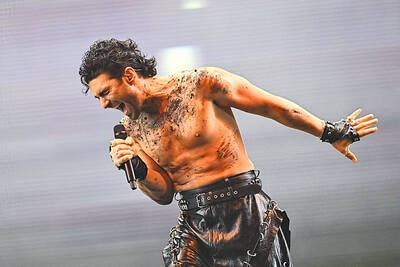

The Eurovision Song Contest has seen a surge in punter interest at the bookmakers, becoming a major betting event, experts said ahead of last night’s giant glamfest in Basel. “Eurovision has quietly become one of the biggest betting events of the year,” said Tomi Huttunen, senior manager of the Online Computer Finland (OCS) betting and casino platform. Betting sites have long been used to gauge which way voters might be leaning ahead of the world’s biggest televised live music event. However, bookmakers highlight a huge increase in engagement in recent years — and this year in particular. “We’ve already passed 2023’s total activity and

Nvidia Corp CEO Jensen Huang (黃仁勳) today announced that his company has selected "Beitou Shilin" in Taipei for its new Taiwan office, called Nvidia Constellation, putting an end to months of speculation. Industry sources have said that the tech giant has been eyeing the Beitou Shilin Science Park as the site of its new overseas headquarters, and speculated that the new headquarters would be built on two plots of land designated as "T17" and "T18," which span 3.89 hectares in the park. "I think it's time for us to reveal one of the largest products we've ever built," Huang said near the

BIG BUCKS: Chairman Wei is expected to receive NT$34.12 million on a proposed NT$5 cash dividend plan, while the National Development Fund would get NT$8.27 billion Taiwan Semiconductor Manufacturing Co (TSMC, 台積電), the world’s largest contract chipmaker, yesterday announced that its board of directors approved US$15.25 billion in capital appropriations for long-term expansion to meet growing demand. The funds are to be used for installing advanced technology and packaging capacity, expanding mature and specialty technology, and constructing fabs with facility systems, TSMC said in a statement. The board also approved a proposal to distribute a NT$5 cash dividend per share, based on first-quarter earnings per share of NT$13.94, it said. That surpasses the NT$4.50 dividend for the fourth quarter of last year. TSMC has said that while it is eager

China yesterday announced anti-dumping duties as high as 74.9 percent on imports of polyoxymethylene (POM) copolymers, a type of engineering plastic, from Taiwan, the US, the EU and Japan. The Chinese Ministry of Commerce’s findings conclude a probe launched in May last year, shortly after the US sharply increased tariffs on Chinese electric vehicles, computer chips and other imports. POM copolymers can partially replace metals such as copper and zinc, and have various applications, including in auto parts, electronics and medical equipment, the Chinese ministry has said. In January, it said initial investigations had determined that dumping was taking place, and implemented preliminary