On wasteland once used for earthquake drills in the small town of Otawara north of Tokyo, Japanese giant Shiseido Co has built its first domestic factory in 36 years, hoping to capitalize on a boom for “Made in Japan” cosmetics.

The Japanese cosmetics industry faces huge competition not only from established players such as L’Oreal SA and Estee Lauder Companies Inc, but increasingly also from the “K-beauty” craze coming from South Korea.

Nevertheless, Japan is more than holding its own, with exports nearly quadrupling since 2013 to ¥546 billion (US$5 billion), according to Japanese Ministry of Finance figures, nearly two-thirds of that going to China and Hong Kong.

Photo: AFP

The domestic industry is also benefitting from an explosion of inbound tourism in recent years ahead of next year’s Tokyo Olympics — in particular a relaxing of visa requirements for Chinese tourists who lap up the latest Japanese cosmetic fads.

Shiseido chief executive Masahiko Uotani said that a focus on the high end of the market and time-honored attention to detail set them apart from the foreign brands seeking to dominate globally.

“We are focusing on prestige, premium brands. Consumers in those categories see the value of Japanese culture,” Uotani said.

“So strategically, we are telling consumers: those brands are from Japan, it’s Japanese R&D [research and development]. And that is becoming a very important competitive value,” he said.

In addition to the new plant in Otawara, Shiseido plans to open two more in Japan before 2022 — a total investment of ¥120 billion — the fastest pace of expansion in the firm’s 150-year history.

Otawara Mayor Tomio Tsukui said the plot for the new factory had been barren since the 1990 tech bubble burst.

“We used to use it to hold exercises to prepare for natural disasters,” Tsukui said.

The 1,000 jobs it creates will make Shiseido the biggest private employer in the town, Tsukui said, putting it down to a drop in value of the yen that has made relocalizing production more profitable.

Shiseido production manager Norio Tadakawa has a different explanation.

“There are six sake breweries” around Otawara, he said.

This is due to the high-quality water around the region — also a fundamental component in making cosmetics.

The three new Shiseido factories in Japan will feature the latest in Japanese tech — from advanced robotics to artificial intelligence — but will also rely heavily on human intervention, especially for the highest-range products.

“Where it’s possible we are introducing robots, AI, and digital production capacities, but we still need people, employees that have high craftsmanship and skills,” Uotani said.

Despite the highest labor costs, Shiseido is not the only company to bring back production to its home base. In 2017, Kose Corp sold its factory in China to boost its presence in Japan.

The gamble on high-cost, high-quality locally made goods appears to be working, GlobalData senior innovation analyst Mitsue Konishi said.

“With quality ingredients, luxurious formulations, elegant packaging, and craftsmanship, cosmetics with the ‘Made in Japan’ tag are gaining appeal in Asian and Western markets,” she said.

However, the flip side of Japanese attention to detail means development times and quality checks take longer, said Shima Yamanaka, an analyst at SMBC Nikko Securities in Tokyo.

“The product timeline of Japanese companies is very long. Safety and quality are high but the product checking takes a long time,” she said.

For example, Kao on Wednesday unveiled a “spray-on skin” that it claims is the world’s first, but it took 10 years to bring to market.

Even Uotani admits that the nimble South Koreans have the advantage on this front.

“They are good competitors... They are quite efficient, their development time is quite short, which allows them to be very reactive to the market,” he said.

DIVIDED VIEWS: Although the Fed agreed on holding rates steady, some officials see no rate cuts for this year, while 10 policymakers foresee two or more cuts There are a lot of unknowns about the outlook for the economy and interest rates, but US Federal Reserve Chair Jerome Powell signaled at least one thing seems certain: Higher prices are coming. Fed policymakers voted unanimously to hold interest rates steady at a range of 4.25 percent to 4.50 percent for a fourth straight meeting on Wednesday, as they await clarity on whether tariffs would leave a one-time or more lasting mark on inflation. Powell said it is still unclear how much of the bill would fall on the shoulders of consumers, but he expects to learn more about tariffs

NOT JUSTIFIED: The bank’s governor said there would only be a rate cut if inflation falls below 1.5% and economic conditions deteriorate, which have not been detected The central bank yesterday kept its key interest rates unchanged for a fifth consecutive quarter, aligning with market expectations, while slightly lowering its inflation outlook amid signs of cooling price pressures. The move came after the US Federal Reserve held rates steady overnight, despite pressure from US President Donald Trump to cut borrowing costs. Central bank board members unanimously voted to maintain the discount rate at 2 percent, the secured loan rate at 2.375 percent and the overnight lending rate at 4.25 percent. “We consider the policy decision appropriate, although it suggests tightening leaning after factoring in slackening inflation and stable GDP growth,”

Greek tourism student Katerina quit within a month of starting work at a five-star hotel in Halkidiki, one of the country’s top destinations, because she said conditions were so dire. Beyond the bad pay, the 22-year-old said that her working and living conditions were “miserable and unacceptable.” Millions holiday in Greece every year, but its vital tourism industry is finding it harder and harder to recruit Greeks to look after them. “I was asked to work in any department of the hotel where there was a need, from service to cleaning,” said Katerina, a tourism and marketing student, who would

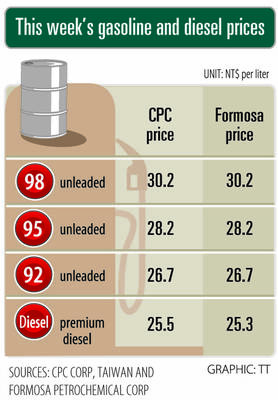

i Gasoline and diesel prices at fuel stations are this week to rise NT$0.1 per liter, as tensions in the Middle East pushed crude oil prices higher last week, CPC Corp, Taiwan (台灣中油) and Formosa Petrochemical Corp (台塑石化) said yesterday. International crude oil prices last week rose for the third consecutive week due to an escalating conflict between Israel and Iran, as the market is concerned that the situation in the Middle East might affect crude oil supply, CPC and Formosa said in separate statements. Front-month Brent crude oil futures — the international oil benchmark — rose 3.75 percent to settle at US$77.01