After clinching a deal with a Chinese battery maker in 2016, James Brown figured bankers would be eager to fund his new lithium mine.

Altura Mining Ltd was racing to ship the raw material from Australia to the world’s biggest electric vehicle market as demand was surging.

Instead, while lithium prices kept rising, Brown spent a Christmas holiday cold-calling lenders and jetted around the globe to raise the money.

Photo: Reuters

Eventually, Minneapolis-based Castlelake LP, a private equity firm, helped arrange US$110 million in bonds, but there was a catch: an interest rate as high as 15 percent, or almost double what banks normally charge for more conventional mining ventures.

“We’d been trying banks we’d known for years,” said Altura managing director Brown, who previously spent 22 years with coal producer New Hope Corp. “They said: Guys we love it, we just don’t have a mandate [for lithium]. If you came to us with coal, gold or iron ore, you’d have no worries.”

Despite bullish forecasts for global demand — especially with accelerating production of electric vehicles — lithium might have a funding problem.

Banks are wary, citing everything from the industry’s poor track record on delivering earlier projects to a lack of insight into a small, opaque market.

Without more investment, supplies of the commodity could remain tight, sustaining a boom that has already has seen prices triple since 2015.

Lithium companies need to invest about US$12 billion to increase output fivefold by 2025 and keep pace with the world’s growing appetite for batteries, according to Galaxy Resources Ltd, an Australian producer seeking to build further operations in Argentina and Canada.

Developers say that, so far, projects are not getting financed fast enough to achieve that leap.

Battery producers and automakers “have absolutely no clue on how long it takes to be able to put a mining project into operation,” said Nemaska Lithium Inc chief executive Guy Bourassa, whose company spent about 18 months piecing together a complex C$1.1 billion (US$830 million) funding program for a mine and processing plant in Quebec.

“There will be a big problem — it’s going to be an impediment” to raising supply, he said.

An “inability to access traditional funds has delayed the development of the sector,” said Brisbane-based Orocobre Ltd chief executive Richard Seville, whose company began lithium sales in 2015 from Argentina and experienced difficulty boosting output. “These projects aren’t easy — so the banks just don’t want to go there.”

While the amount of debt raised by miners, including loans and bonds, rose last year to about US$255 billion, project-specific financing of about US$13 billion last year is more than 70 percent lower than in 2014, according to data compiled by Bloomberg.

So far this year, about US$6.1 billion in total has been issued for projects.

Some new deposits are being developed in riskier emerging markets or nations on the edge of investment-grade credit ratings, such as Argentina, said Lee Garvey at Marsh & McLennan Cos, an insurance broker that has seen an increase in policies related to lithium projects.

“With lithium, there is the added complexity that there is not much clarity around the end product and what the royalty should be,” Garvey said. “This probably makes the whole thing more challenging, particularly in frontier markets.”

It typically takes two years to build a lithium operation and five years to repay the project loan, said Simon Price, a partner and cofounder at Perth-based Azure Capital Ltd, which has advised miners on financing.

That means lenders need confidence in a seven-year outlook for the market, he said.

That price outlook is an industry flash point.

Morgan Stanley says there will be a surplus as soon as next year because of rising output and forecasts lithium carbonate prices to halve through 2021, according to a note.

Citigroup Inc also expects prices to decline as production increases, but boosting supplies might not be easy.

By 2020, it is possible that only a third of planned new capacity will be available at the processing plants needed to convert mined raw materials into battery chemicals, Orocobre said.

Some alternative funding sources for lithium have emerged, including hedge funds offering higher-yield debt or credit funds formed to lend to projects.

They are more expensive, but “you build your project and you are in business now when the market is very strong,” Price said.

Lithium users are also stepping in with funding.

POSCO, the South Korean steelmaker that is ramping up its battery-making business, and Great Wall Motor Co, China’s top SUV producer, have both invested in Pilbara Minerals to speed up project development.

Tesla Inc in May signed a supply deal with Kidman, a boon for the Australian developer as it seeks to finance a mine and plant.

Still, electrifying the world’s vehicle fleet will require vast sums for new mines and funding will remain a challenge for smaller companies, Bourassa said.

Volkswagen AG alone plans to spend about 50 billion euros (US$58 billion) on batteries as it seeks to build electric versions of 300 models.

“Imagine how many tonnes of lithium salts it takes to make those batteries,” Bourassa said.

DIVIDED VIEWS: Although the Fed agreed on holding rates steady, some officials see no rate cuts for this year, while 10 policymakers foresee two or more cuts There are a lot of unknowns about the outlook for the economy and interest rates, but US Federal Reserve Chair Jerome Powell signaled at least one thing seems certain: Higher prices are coming. Fed policymakers voted unanimously to hold interest rates steady at a range of 4.25 percent to 4.50 percent for a fourth straight meeting on Wednesday, as they await clarity on whether tariffs would leave a one-time or more lasting mark on inflation. Powell said it is still unclear how much of the bill would fall on the shoulders of consumers, but he expects to learn more about tariffs

NOT JUSTIFIED: The bank’s governor said there would only be a rate cut if inflation falls below 1.5% and economic conditions deteriorate, which have not been detected The central bank yesterday kept its key interest rates unchanged for a fifth consecutive quarter, aligning with market expectations, while slightly lowering its inflation outlook amid signs of cooling price pressures. The move came after the US Federal Reserve held rates steady overnight, despite pressure from US President Donald Trump to cut borrowing costs. Central bank board members unanimously voted to maintain the discount rate at 2 percent, the secured loan rate at 2.375 percent and the overnight lending rate at 4.25 percent. “We consider the policy decision appropriate, although it suggests tightening leaning after factoring in slackening inflation and stable GDP growth,”

Greek tourism student Katerina quit within a month of starting work at a five-star hotel in Halkidiki, one of the country’s top destinations, because she said conditions were so dire. Beyond the bad pay, the 22-year-old said that her working and living conditions were “miserable and unacceptable.” Millions holiday in Greece every year, but its vital tourism industry is finding it harder and harder to recruit Greeks to look after them. “I was asked to work in any department of the hotel where there was a need, from service to cleaning,” said Katerina, a tourism and marketing student, who would

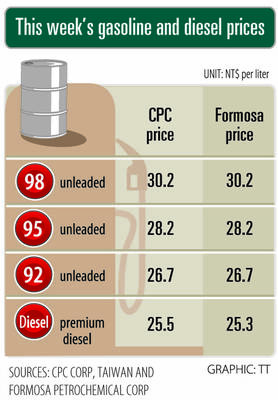

i Gasoline and diesel prices at fuel stations are this week to rise NT$0.1 per liter, as tensions in the Middle East pushed crude oil prices higher last week, CPC Corp, Taiwan (台灣中油) and Formosa Petrochemical Corp (台塑石化) said yesterday. International crude oil prices last week rose for the third consecutive week due to an escalating conflict between Israel and Iran, as the market is concerned that the situation in the Middle East might affect crude oil supply, CPC and Formosa said in separate statements. Front-month Brent crude oil futures — the international oil benchmark — rose 3.75 percent to settle at US$77.01