BMW has said it would be forced to close its production sites in the UK, putting 8,000 jobs at risk, if components for Mini and Rolls-Royce cars are caught up in customs delays after Brexit.

In its starkest warning over Brexit yet, the customs manager of the German carmaker’s UK operations said its manufacturing setup would not be able to cope with obstructions to its supply chain.

“We always said we can do our best and prepare everything, but if, at the end of the day the supply chain will have a stop at the border, then we cannot produce our products in the UK,” Stephan Freismuth told the Financial Times.

Photo: EPA-EFE

BMW employs 8,000 people in the UK, including 4,500 at its flagship plant in Cowley, Oxford, where it produces the Mini.

The BMW warning came ahead of a key motor manufacturing industry conference yesterday, where a series of automotive executives from companies with major UK manufacturing operations are expected to express serious concerns about the future of their businesses.

The industry hopes a series of warnings from companies, including Honda, Volvo and Ford, will act as a wake-up call to British Prime Minister Theresa May, who made exiting the customs union and the single market one of her early red lines.

“We don’t want to give up our UK plants,” Freismuth said. “We do our best to maintain business continuity.”

“If you have a stop for one day, it costs a lot of money, but at the end if there are more stops our management has to decide how this can be sorted,” he added.

BMW has four plants in the UK, including a Rolls-Royce assembly unit in Goodwood in Sussex and an engine plant at Hams Hall in Birmingham. It also has a metal-pressing facility in Swindon.

On Saturday, thousands of workers enjoyed a summer family fair at the flagship Mini plant in Oxford where food, a Ferris wheel and music were laid on by the company.

A full or part closure would have a devastating impact on the surrounding area, the poorest part of Oxford, which relies heavily on BMW for employment.

The auto industry employs about 860,000 people in the UK, with virtually all production relying on just-in-time processes, the term used to describe components arriving seamlessly from multiple domestic and international destinations to avoid costly stockpiling of parts.

The port of Dover and Getlink, which runs Eurotunnel, have said even a two-minute delay at the ports could mean queues up to 27km long, with severe consequences for all just-in-time production and the supply of fresh produce.

BMW’s warning came just days after Airbus, an important employer in Wales and the Bristol area, said it would be forced to leave the UK if Brexit leads to its operations becoming uncompetitive.

The Airbus intervention on Friday was initially greeted with dismay by the government, with British Secretary of State for Health and Social Care Jeremy Hunt castigating the Franco-German maker of the A380 aircraft for making “inappropriate” remarks.

British Secretary of State for Foreign and Commonwealth Affairs Boris Johnson was also reported to have reacted privately by saying: “Fuck business.”

Last week, the port of Dover warned there could be emergency traffic congestion management, including turning parts of the M20 into a lorry park, if there were any delays at the port.

The chief executive of the society of Motor Manufacturers and Trade was yesterday expected to open the trade body’s automotive summit with a strong message to the government.

The Japanese ambassador to Britain was also scheduled to speak and is expected to voice concern about the future of Nissan’s Sunderland factory, Toyota’s Derby operations and Honda’s Swindon site post-Brexit.

BMW’s warning came hours after business leaders from the US, Canada, Japan and India told the British government to solve the Brexit issue urgently or put more than £100 billion (US$132.6 million) worth of trade at risk.

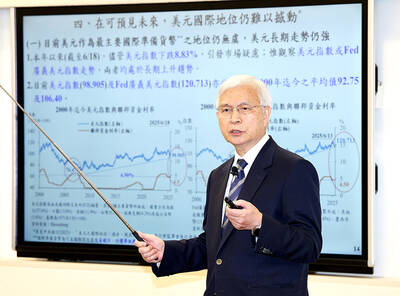

DIVIDED VIEWS: Although the Fed agreed on holding rates steady, some officials see no rate cuts for this year, while 10 policymakers foresee two or more cuts There are a lot of unknowns about the outlook for the economy and interest rates, but US Federal Reserve Chair Jerome Powell signaled at least one thing seems certain: Higher prices are coming. Fed policymakers voted unanimously to hold interest rates steady at a range of 4.25 percent to 4.50 percent for a fourth straight meeting on Wednesday, as they await clarity on whether tariffs would leave a one-time or more lasting mark on inflation. Powell said it is still unclear how much of the bill would fall on the shoulders of consumers, but he expects to learn more about tariffs

NOT JUSTIFIED: The bank’s governor said there would only be a rate cut if inflation falls below 1.5% and economic conditions deteriorate, which have not been detected The central bank yesterday kept its key interest rates unchanged for a fifth consecutive quarter, aligning with market expectations, while slightly lowering its inflation outlook amid signs of cooling price pressures. The move came after the US Federal Reserve held rates steady overnight, despite pressure from US President Donald Trump to cut borrowing costs. Central bank board members unanimously voted to maintain the discount rate at 2 percent, the secured loan rate at 2.375 percent and the overnight lending rate at 4.25 percent. “We consider the policy decision appropriate, although it suggests tightening leaning after factoring in slackening inflation and stable GDP growth,”

Meta Platforms Inc offered US$100 million bonuses to OpenAI employees in an unsuccessful bid to poach the ChatGPT maker’s talent and strengthen its own generative artificial intelligence (AI) teams, OpenAI CEO Sam Altman has said. Facebook’s parent company — a competitor of OpenAI — also offered “giant” annual salaries exceeding US$100 million to OpenAI staffers, Altman said in an interview on the Uncapped with Jack Altman podcast released on Tuesday. “It is crazy,” Sam Altman told his brother Jack in the interview. “I’m really happy that at least so far none of our best people have decided to take them

As they zigzagged from one machine to another in the searing African sun, the workers were covered in black soot. However, the charcoal they were making is known as “green,” and backers hope it can save impoverished Chad from rampant deforestation. Chad, a vast, landlocked country of 19 million people perched at the crossroads of north and central Africa, is steadily turning to desert. It has lost more than 90 percent of its forest cover since the 1970s, hit by climate change and overexploitation of trees for household uses such as cooking, officials say. “Green charcoal” aims to protect what