Taipei Times: What is your view on the DRAM industry in the second half of this year?

David Sun (孫大衛): Prospects for the DRAM industry are looking good, if the market situation stays normal. The use of DRAM is expanding from PCs to a lot of new products such as mobile phones, videos and servers.

And supply is limited. Most DRAM companies are migrating to next-generation technologies, which will take time to churn out the massive output.

PHOTO: CNA

I believe supply will match demand, or will even be less than demand. Most companies should be able to generate cash and make profits.

TT: What is your take on growing capital spending from DRAM companies, especially Samsung Electronics of South Korea this year? Samsung said last month it intends to spend a total of 18 trillion won (US$15.84 billion) in capital spending this year, of which 9 trillion won would be spent on memory business.

Sun: Samsung produces a variety of products. I do not think it will bet the money solely on DRAM. And there is the risk of breaking anti-trust rules if Samsung greatly expands capacity to boost market share over 50 percent.

With so big a market share, I do not expect Samsung to wage a price war to force marginal players out of the market at the expense of losing big money. I believe Samsung sees the business potential.

TT: Do you think the benchmark DDR3 DRAM price will fall below US$2.5 per unit?

Sun: Frankly, DRAM companies should feel pressure to reduce prices as supply is exceeding demand. But, I don’t expect the spot price of DDR3 will fall to less than US$2.5 per unit in the short term, as PC makers eventually have to increase memory space on computers [along with sales of new operating systems, or software later this year].

TT: Will the 30 percent salary hike planned by Hon Hai Precision Industry Co (鴻海精密), which owns Foxconn in China, for its Chinese employees, following a series of suicides, make you rethink future factory expansion in China?

Sun: We have two factories in Shangahi and Shenzhen. We employ over 2,000 workers there. I think the cost of labor is still lower there than in Taiwan, even after the 30 percent hike in monthly wages.

But we are very cautious about capacity expansion across the strait. We don’t expand capacity aggressively. Our strategy is outsourcing half our manufacturing to other companies in China and Taiwan, meaning that we will increase outsourcing to cope with growing business.

Kingston operates a factory in Hsinchu, where we employ about 800 people, including a sales marketing department.

TT: Kingston has been making money every year since its inception 23 years ago and generated US$2.46 billion in revenues last year [based on DRAMeXchange Technology Inc's (集邦科技) tally] with a small number of staff — just 3,800 in total. What is the secret behind this?

Sun: Making memory modules is a very simple business. The key is how to manage variables in the memory industry. We are a small company, which allows us to make decisions fast and with greater flexibility than big conglomerates.

Besides, managing the supply chain is also important. Kingston ships 30 million memory units a day to 30 countries and 97 percent of them are produced on the same day. We almost have no inventory at all.

Operating efficiency is also important. We can churn out 30 percent more high-quality output than our competitors on the same machine.

What makes this happen? Good employee understanding is essential. Most of our employees have been working with the company for over 10 years and they are willing to do good things for the company.

We do not have a strict appraisal system to manage the company as most companies do. We even have to educate our employees that they do not have to make more money than last year.

IN THE AIR: While most companies said they were committed to North American operations, some added that production and costs would depend on the outcome of a US trade probe Leading local contract electronics makers Wistron Corp (緯創), Quanta Computer Inc (廣達), Inventec Corp (英業達) and Compal Electronics Inc (仁寶) are to maintain their North American expansion plans, despite Washington’s 20 percent tariff on Taiwanese goods. Wistron said it has long maintained a presence in the US, while distributing production across Taiwan, North America, Southeast Asia and Europe. The company is in talks with customers to align capacity with their site preferences, a company official told the Taipei Times by telephone on Friday. The company is still in talks with clients over who would bear the tariff costs, with the outcome pending further

A proposed 100 percent tariff on chip imports announced by US President Donald Trump could shift more of Taiwan’s semiconductor production overseas, a Taiwan Institute of Economic Research (TIER) researcher said yesterday. Trump’s tariff policy will accelerate the global semiconductor industry’s pace to establish roots in the US, leading to higher supply chain costs and ultimately raising prices of consumer electronics and creating uncertainty for future market demand, Arisa Liu (劉佩真) at the institute’s Taiwan Industry Economics Database said in a telephone interview. Trump’s move signals his intention to "restore the glory of the US semiconductor industry," Liu noted, saying that

STILL UNCLEAR: Several aspects of the policy still need to be clarified, such as whether the exemptions would expand to related products, PwC Taiwan warned The TAIEX surged yesterday, led by gains in Taiwan Semiconductor Manufacturing Co (TSMC, 台積電), after US President Donald Trump announced a sweeping 100 percent tariff on imported semiconductors — while exempting companies operating or building plants in the US, which includes TSMC. The benchmark index jumped 556.41 points, or 2.37 percent, to close at 24,003.77, breaching the 24,000-point level and hitting its highest close this year, Taiwan Stock Exchange (TWSE) data showed. TSMC rose NT$55, or 4.89 percent, to close at a record NT$1,180, as the company is already investing heavily in a multibillion-dollar plant in Arizona that led investors to assume

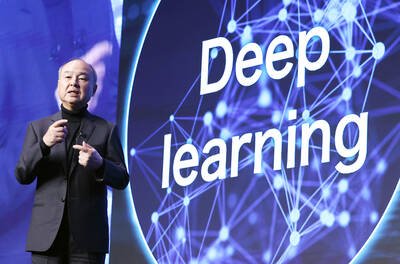

AI: Softbank’s stake increases in Nvidia and TSMC reflect Masayoshi Son’s effort to gain a foothold in key nodes of the AI value chain, from chip design to data infrastructure Softbank Group Corp is building up stakes in Nvidia Corp and Taiwan Semiconductor Manufacturing Co (TSMC, 台積電), the latest reflection of founder Masayoshi Son’s focus on the tools and hardware underpinning artificial intelligence (AI). The Japanese technology investor raised its stake in Nvidia to about US$3 billion by the end of March, up from US$1 billion in the prior quarter, regulatory filings showed. It bought about US$330 million worth of TSMC shares and US$170 million in Oracle Corp, they showed. Softbank’s signature Vision Fund has also monetized almost US$2 billion of public and private assets in the first half of this year,