The sour smell of fermenting soy beans hangs in the air at the Lee Kum Kee (李錦記) sauce factory as company chairman Eddy Lee (李惠民) explains why he's haunted by a old Chinese saying: "Wealth doesn't go beyond the third generation."

The family firm -- which began making sauces more than 100 years ago and is now a major global brand -- is already being run by the fourth generation. And the fifth wave is showing no interest in taking over, Lee says.

"There are so many family businesses that fail to continue. We want to break that curse," Lee, 50, says from a sofa in the living room of his bungalow on the factory's grounds, with a huge green lawn and a grove of banana trees.

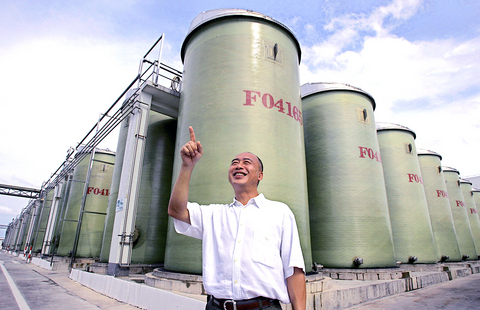

PHOTO: AP

It's the classic succession issue -- one of the most serious challenges facing family businesses around the world. How do you groom the next generation, restructure the company for new leadership and avoid the familial feuding that has sunk so many others?

The Lee family has decided to take a bold step: hiring an outsider to be the chief executive officer by the end of this year. Until now, most top management spots have been filled by family members or longtime employees.

"We believe the company is becoming big enough that it's not an easy job to do anymore. It requires more management skills," Lee said.

It's a huge move for a company founded in 1888. The firm's first product was oyster sauce.

Lee's great grandfather developed the sauce recipe by accident. The restaurateur left a pot of oyster soup boiling too long and discovered the broth had been reduced to a thick, dark brown sauce that was tastier than the soup.

The company moved to Hong Kong in 1946 and began quickly expanding its global business, selling its premium sauces to wealthy Chinese living in San Francisco, London, New York and Hawaii. Now Lee Kum Kee sells nearly 300 sauces and condiments, including chili garlic sauce, minced ginger, sesame oil and soy sauce, in grocery stores worldwide.

Lee is tightlipped about the company's financials and only shares vague figures about sales and production: "Every year, we have 15 percent to 20 percent, at the most 25 percent, growth ... But this is not what we want. We want breakthroughs all the time."

Lee said the company is making a big push to become the leader in China's huge soy sauce market.

"I think if we can be No. 1 in China, we have a good chance to be No. 1 in the world in Asian or Chinese sauces ... We're currently No. 2," he said.

Lee Kum Kee produces about 100,000 tonnes of soy sauce each year, he said. The company has a factory in Hong Kong, two in China and distribution centers and sales offices in the US and Europe.

The plant in Xinhui employs about 1,400 people and has several football field-sized spaces with rows of silo-like fermentation tanks that each hold enough soy sauce to fill 100,000 bottles.

Lee said the firm tries to work out problems by having regular family retreats. The family -- four brothers, a sister and two parents -- also holds an election every two years for the chairmanship, said Lee, who will serve until 2008.

Lee said the company has had a difficult time searching for a CEO. It needs someone -- preferably ethnic Chinese -- with global experience who understands Chinese food culture and the sauce business. The person also has to understand how to work with the family, he said.

This is a tough time to be looking for such a person, said Maris Martinsons, associate professor of management at City University of Hong Kong: "The Chinese economy is booming and lots of other companies are looking for the same profile."

He said Lee Kum Kee was smart to be seeking leadership from the outside, but said there were risks for executives considering the job.

"If the company is not publicly listed, it hasn't been properly vetted by the outside investment community," he said. "There may be skeletons in the family business' closet and that would make the executive think twice before he or she takes the job."

Quanta Computer Inc (廣達) chairman Barry Lam (林百里) is expected to share his views about the artificial intelligence (AI) industry’s prospects during his speech at the company’s 37th anniversary ceremony, as AI servers have become a new growth engine for the equipment manufacturing service provider. Lam’s speech is much anticipated, as Quanta has risen as one of the world’s major AI server suppliers. The company reported a 30 percent year-on-year growth in consolidated revenue to NT$1.41 trillion (US$43.35 billion) last year, thanks to fast-growing demand for servers, especially those with AI capabilities. The company told investors in November last year that

United Microelectronics Corp (UMC, 聯電) forecast that its wafer shipments this quarter would grow up to 7 percent sequentially and the factory utilization rate would rise to 75 percent, indicating that customers did not alter their ordering behavior due to the US President Donald Trump’s capricious US tariff policies. However, the uncertainty about US tariffs has weighed on the chipmaker’s business visibility for the second half of this year, UMC chief financial officer Liu Chi-tung (劉啟東) said at an online earnings conference yesterday. “Although the escalating trade tensions and global tariff policies have increased uncertainty in the semiconductor industry, we have not

Intel Corp has named Tasha Chuang (莊蓓瑜) to lead Intel Taiwan in a bid to reinforce relations between the company and its Taiwanese partners. The appointment of Chuang as general manager for Intel Taiwan takes effect on Thursday, the firm said in a statement yesterday. Chuang is to lead her team in Taiwan to pursue product development and sales growth in an effort to reinforce the company’s ties with its partners and clients, Intel said. Chuang was previously in charge of managing Intel’s ties with leading Taiwanese PC brand Asustek Computer Inc (華碩), which included helping Asustek strengthen its global businesses, the company

Power supply and electronic components maker Delta Electronics Inc (台達電) yesterday said it plans to ship its new 1 megawatt charging systems for electric trucks and buses in the first half of next year at the earliest. The new charging piles, which deliver up to 1 megawatt of charging power, are designed for heavy-duty electric vehicles, and support a maximum current of 1,500 amperes and output of 1,250 volts, Delta said in a news release. “If everything goes smoothly, we could begin shipping those new charging systems as early as in the first half of next year,” a company official said. The new