Luke Soules was one of the first on the planet to get his hands on an iPad. And he wasted no time taking it apart.

After staking out three locations in the Eastern US, Soules — co-founder of teardown firm iFixit — cracked the device open on Saturday to unearth NAND flash memory by Samsung Electronics, an LCD display from LG Display and microchips from Broadcom Corp, Texas Instruments Inc and NXP Semiconductor.

Soules and his outfit provide and advise on components in Apple gadgets — and also identifies them. The work of teardown firms such as iFixit may prove crucial in identifying which manufacturer gets its parts into a device expected to sell upwards of 5 million units this year alone.

PHOTO: REUTERS

Soules had slept overnight in the parking lot outside an Apple mall store in Richmond, Virginia. He was the first to walk out of the store, moments after the outlet opened at 9am, iPad in hand.

Store employees clapped and gave him high-fives. He grinned, but moved quickly. There was work to do.

Without a second’s dawdling, Soules hopped in a waiting car and raced a few short kilometers to the house of a friend, where he had his tools of destruction ready to go. He barely paused to admire the iPad out of the box. He didn’t even turn it on.

The secretive Apple is famous for designing sealed-up devices intended to discourage nosy gadget heads from poking around in them, and the iPad was no different.

The iPad had no screws. But working with a tool called a spudger, it took Soules only 10 minutes to separate the iPad’s handsome, 24.6cm facing from its silver-backed casing.

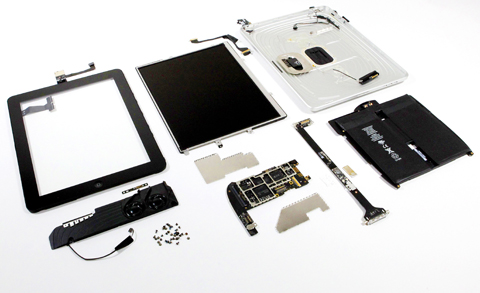

He surveyed the iPad’s design, a maze of parts that would be utterly inscrutable to most people.

“That’s very, very nice,” he said almost reverentially.

Teardown firms are hired by an array of clients, their data used for competitive intelligence, in patent disputes or to keep current on industry benchmarks.

By 9:30am, Soules had turned the iPad inside out and was sharing its secrets with the world.

There is strong competition to be first to tear open Apple devices and reveal the design, chips and components within and iFixit has gained a measure of fame for their work.

Months of anticipation had built ahead of the iPad launch and — at least in technology circles — almost as much excitement about what’s on the inside of the device.

Within 45 minutes, iFixit had left the iPad — the gleaming symbol of Apple’s technological wizardry — in tatters, its various parts naked against a crisp white backdrop.

Soules moved at a rapid clip, narrating as he took pictures and streamed to colleague Kyle Wiens and others in California, who were posting them online and helping identify parts.

IFixit’s near-live teardowns have become staples for gadget fans during Apple product launches.

As a veteran of many previous efforts, Soules was prepared for any tricks Apple might throw his way, but the iPad didn’t prove to be too enormous of a challenge to take apart, as some previous devices have.

Soules had removed the main circuit board of the iPad by 10am. The 10.2cm long, 28g board was covered by an electromagnetic interference shield, and underneath were all the microprocessors that make the device tick.

“The vast majority of the brains of the iPad are on this little board. It’s amazing what they can fit into such a small space,” Soules said.

One of first identifiable parts was the NAND flash memory, which was made by Samsung, which has supplied components for other Apple devices. Soules also quickly noted chips from Broadcom and Texas Instruments.

There were also at least three chips carrying Apple branding. Apple is known to hide the identities of some chipmakers in its products by having them stamp an Apple logo on their parts. The main iPad chip is an Apple creation; its very own A4 processor controls the iPad’s programs.

IFixit determined that Samsung is manufacturing the A4 chip for Apple.

After removing the circuit board, Soules dug in further using a Torx screwdriver to manipulate the minuscule screws inside the iPad. His fingernails gingerly pried open casings.

“The teardown process is bit easier if I keep my fingernails on the long side,” he said.

Soules discovered the iPad’s battery is not soldered into place, which means that replacing it is possible for the do-it-yourself crowd.

IFixit promotes device repair as a means to cut down on electronic waste.

Apple requires users to mail iPad units back to the company, which will change the battery for a hefty fee.

By 10:45am Soules was cautiously fiddling with the iPad’s display, the most expensive component.

While he was unable to determine who made the display on his unit, another iFixit teardown at a different location revealed one from LG, meaning Apple could be using displays from more than one supplier.

Besides Richmond, iFixit had also ordered iPads at addresses near Indianapolis and Orlando, Florida. The company had people in both areas, home to FedEx shipping hubs.

IFixit thought it might be able to get a few hours jump on the competition by staking out the FedEx hubs the morning of the launch, to intercept one of the devices.

But that didn’t pan out, so they resorted to standing in line — at the head of the line actually — in three cities.

The Federal Communications Commission also managed to steal at least some of iFixit’s thunder.

Bloggers discovered on Friday that the FCC had posted pictures of the insides of pre-production iPads on its Web site, even though Apple had requested that they keep them confidential.

IFixit spent much of the night identifying the parts, which were not necessarily the same as those in real iPads.

By noon on Saturday, the bulk of the iPad teardown was done. But there will be at least another week of analysis, using sophisticated equipment that can cut into components to determine how they were made, and who made them.

DAREDEVIL: Honnold said it had always been a dream of his to climb Taipei 101, while a Netflix producer said the skyscraper was ‘a real icon of this country’ US climber Alex Honnold yesterday took on Taiwan’s tallest building, becoming the first person to scale Taipei 101 without a rope, harness or safety net. Hundreds of spectators gathered at the base of the 101-story skyscraper to watch Honnold, 40, embark on his daredevil feat, which was also broadcast live on Netflix. Dressed in a red T-shirt and yellow custom-made climbing shoes, Honnold swiftly moved up the southeast face of the glass and steel building. At one point, he stepped onto a platform midway up to wave down at fans and onlookers who were taking photos. People watching from inside

A Vietnamese migrant worker yesterday won NT$12 million (US$379,627) on a Lunar New Year scratch card in Kaohsiung as part of Taiwan Lottery Co’s (台灣彩券) “NT$12 Million Grand Fortune” (1200萬大吉利) game. The man was the first top-prize winner of the new game launched on Jan. 6 to mark the Lunar New Year. Three Vietnamese migrant workers visited a Taiwan Lottery shop on Xinyue Street in Kaohsiung’s Gangshan District (崗山), a store representative said. The player bought multiple tickets and, after winning nothing, held the final lottery ticket in one hand and rubbed the store’s statue of the Maitreya Buddha’s belly with the other,

‘NATO-PLUS’: ‘Our strategic partners in the Indo-Pacific are facing increasing aggression by the Chinese Communist Party,’ US Representative Rob Wittman said The US House of Representatives on Monday released its version of the Consolidated Appropriations Act, which includes US$1.15 billion to support security cooperation with Taiwan. The omnibus act, covering US$1.2 trillion of spending, allocates US$1 billion for the Taiwan Security Cooperation Initiative, as well as US$150 million for the replacement of defense articles and reimbursement of defense services provided to Taiwan. The fund allocations were based on the US National Defense Authorization Act for fiscal 2026 that was passed by the US Congress last month and authorized up to US$1 billion to the US Defense Security Cooperation Agency in support of the

‘COMMITTED TO DETERRENCE’: Washington would stand by its allies, but it can only help as much as countries help themselves, Raymond Greene said The US is committed to deterrence in the first island chain, but it should not bear the burden alone, as “freedom is not free,” American Institute in Taiwan Director Raymond Greene said in a speech at the Institute for National Defense and Security Research’s “Strengthening Resilience: Defense as the Engine of Development” seminar in Taipei yesterday. In the speech, titled “Investing Together and a Secure and Prosperous Future,” Greene highlighted the contributions of US President Donald Trump’s administration to Taiwan’s defense efforts, including the establishment of supply chains for drones and autonomous systems, offers of security assistance and the expansion of