It was a tranquil afternoon at a mountain village in Chinshan Township, Taipei County (台北縣金山鄉). Chiang Jung-yuan (江榮原), head of Taiwan's first brand specializing in making handmade soap out of natural ingredients, A-yuan Soap (阿原肥皂), and his obliging assistant led the way into what looked like a farmhouse studio situated in the middle of a fallow field. Inside, the sweet perfume of herbs permeated the air and several housewives were busy cutting semi-finished soap into pieces and stamping them with names such as Asiatic wormwood, common lantana and licorice.

"Chinshan is a withering town. The young people are long gone … I am initiating a community development project of my own, working with locals to make their town the homeland of soap," said Chiang, whose study of plants and chronic skin problems prompted him to embark on his now burgeoning soap business some 18 months ago.

Spending most of the day studying herbal concoctions and hand-making soaps together with his 11 local employees at the studio, the 40-something entrepreneur hasn't always enjoyed such a peaceful existence. Physically and spiritually exhausted after 15 years of running advertising companies in Taipei, Chiang's life-long interest in Chinese medicine led him down a different path a few years ago with help from his herbalist friends and doctors of Chinese medicine. Soon he was using the healing powers of natural ingredients such as organic lemons from Taitung (台東), Asiatic wormwood from an organic planter in Changhua (彰化), aloe vera from Penghu (澎湖) to mineral water from Wanli (萬里) and black sesame and camellia oils manufactured in local factories to make a series of preservative-free products.

PHOTOS COURTESY OF A-YUAN SOAP

Ingredients are selected not for their pretty colors but their supposedly curative effects and are tested on humans before reaching store shelves. The key raw material is fat made from edible oils renowned for their therapeutic powers, the making of which illustrates the meticulous methods employed by Chiang. He had several water samples from locations across the island tested at research centers before determining that Wanli's would produce the finest soap.

A-yuan soaps are also the fruits of collective labor. From the drying and grinding of fruits, vegetables and herbs to the natural process of saponification and packing, the SGS (the world's leading testing and certification company) approved products take two months preparation before being shipped while the hundreds of thousands soaps manufactured monthly by the dozen employees can hardly meet the expanding market demand.

Mechanizing the process isn't an option for Chiang because "local residents need the jobs and a group of villagers happily chatting while hand-packing soaps makes a more beautiful image droning machinery does," the soap-maker said.

Yet when Chiang and his partners began their business, locally handmade soaps were virtually unheard of. "When we first began operations, there was no market for our products. My partners and I traveled across the island and knocked on doors of shops and stores with bags of soaps on our backs … We got rejected all the time and the pain from carrying heavy loads still troubles us today," Chiang said.

Chiang's persistence and the quality of his products have gradually built up a base of clients. Local media quickly trumpeted the budding business as an ideal story of success while investors approached Chiang for a lucrative venture into the global market.

"Many people compared A-yuan Soap with international brands such as Lush and said our products can definitely sell because of their strong localized flavors and exoticism. But what I am concern about is not profits but the land and its people," said Chiang, who chooses to plough money into training his staff made up of local old folk, middle-aged housewives and the mentally handicapped rather than flashy ad campaigns and marketing.

Moving to Chinshan to participate in local affairs and understand what the villagers need, Chiang envisions A-yuan Soap not merely as an enterprise but a community development project that helps locals better their lives with a profitable handicraft that can be passed down from generation to generation.

"Before I was concerned only for my own well being and my life was empty. Now my responsibility is for the whole community and I have to think of others and take care of my staff as my own family. And guess what? I have never been happier," said Chiang.

The son of a blue-collar family from the Linkou (林口) countryside, Chiang has an inherent affinity to human labor and his next undertaking is to re-awaken people's recognition on the value and aesthetics of labor and handiworks with the establishment of what he dubs the "ecological factory," a botanic garden-cum-manufactory where the public can gain first-hand appreciation of nature's gifts and the beauty of manual labor.

"We will soon start looking for land for our ecological factory. It will be shared with all those people making honest and healthy goods despite financial difficulties and lack of distribution channels. We have met so many of them along the way and believe a difference will be made if we can share resources and work in a cooperative manner," said the idealistic entrepreneur.

For those interested in A-yuan's handmade products, enquire at local organic stores or visit www.taiwansoap.com.tw. For each online purchase, A-yuan will donate three percent of the total purchase to charity groups such as the Genesis Social Welfare Foundation (創世基金會) and the Garden of Hope Foundation (勵馨社會福利基金會).

On a harsh winter afternoon last month, 2,000 protesters marched and chanted slogans such as “CCP out” and “Korea for Koreans” in Seoul’s popular Gangnam District. Participants — mostly students — wore caps printed with the Chinese characters for “exterminate communism” (滅共) and held banners reading “Heaven will destroy the Chinese Communist Party” (天滅中共). During the march, Park Jun-young, the leader of the protest organizer “Free University,” a conservative youth movement, who was on a hunger strike, collapsed after delivering a speech in sub-zero temperatures and was later hospitalized. Several protesters shaved their heads at the end of the demonstration. A

Google unveiled an artificial intelligence tool Wednesday that its scientists said would help unravel the mysteries of the human genome — and could one day lead to new treatments for diseases. The deep learning model AlphaGenome was hailed by outside researchers as a “breakthrough” that would let scientists study and even simulate the roots of difficult-to-treat genetic diseases. While the first complete map of the human genome in 2003 “gave us the book of life, reading it remained a challenge,” Pushmeet Kohli, vice president of research at Google DeepMind, told journalists. “We have the text,” he said, which is a sequence of

In August of 1949 American journalist Darrell Berrigan toured occupied Formosa and on Aug. 13 published “Should We Grab Formosa?” in the Saturday Evening Post. Berrigan, cataloguing the numerous horrors of corruption and looting the occupying Republic of China (ROC) was inflicting on the locals, advocated outright annexation of Taiwan by the US. He contended the islanders would welcome that. Berrigan also observed that the islanders were planning another revolt, and wrote of their “island nationalism.” The US position on Taiwan was well known there, and islanders, he said, had told him of US official statements that Taiwan had not

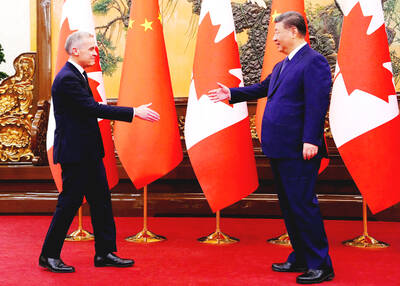

Britain’s Keir Starmer is the latest Western leader to thaw trade ties with China in a shift analysts say is driven by US tariff pressure and unease over US President Donald Trump’s volatile policy playbook. The prime minister’s Beijing visit this week to promote “pragmatic” co-operation comes on the heels of advances from the leaders of Canada, Ireland, France and Finland. Most were making the trip for the first time in years to refresh their partnership with the world’s second-largest economy. “There is a veritable race among European heads of government to meet with (Chinese leader) Xi Jinping (習近平),” said Hosuk Lee-Makiyama, director