The landscape in Houli Township, Taichung County (台中縣后里鄉) is dotted with plain-looking factories that rise above green rice fields. The area is the leading production center of musical instruments in Taiwan, and in many ways it epitomizes the past successes and current challenges faced by Taiwan's small- and medium-sized enterprises.

"All across Taichung County, you can see unlicensed factories that were built on farmland. This is where Taiwan's economic miracle started," said Chad Huang (黃琪源), the marketing manager of Wang Percussion Instrument Co., Ltd. (川智股份有限公司).

Founded in 1956 as a family business making handcrafted saxophones, Wang Percussion, formerly known as Dong Jou Musical (東洲樂器), has risen to meet the challenges of globalization by specializing in high-quality jazz drum sets and percussion instruments. Some 99.5 percent of its products are exported to Japan, Europe and North America.

PHOTO COURTESY OF WANG PERCUSSION

But the road to its current prosperity has not been smooth. "In 1970s the large company Kong Hsue Sheh (功學社) entered the saxophone market with mass-produced, low-cost products. Half of the more than 100 small manufacturers in Houli were wiped out, and now only 10 to 15 family-owned businesses remain," Huang said. (Kong Hsue Sheh, among other things, distributes scooters made by Japan's Yamaha Motor Co.)

Facing its first significant setback, Wang Percussion quickly switched to making tambourines, then jazz drums, and became the original equipment manufacturer (OEM) for international brands such as Japan's Tama, and US firms Drum Workshop, Gretsch, Ludwig and Ddrum. A textbook example of the remarkable strength and perseverance of local small- and medium-sized enterprises (SMEs), the company now enjoys an average annual turnover of NT$360 million, its 70 employees producing around 5,000 drum sets each month.

The success was hard-earned, as Wang Percussion was one of the few SMEs willing to invest large sums in technology development without government aid. Working with a local machinery manufacturer in the early 1990s, the company developed the first specialized machines for the mechanization of drum shell production and quality control in Taiwan. It is also the only company in the world that makes bamboo drum shells for Drum Workshop.

"If you want to produce quality products, it's essential that you have enough capital. But as relocations from Taiwan to China continue, very few local manufacturers are willing to make the needed investments," Huang said.

Indeed, fierce competition from the other side of the Taiwan Strait has thrust the industry into a state of crisis. Before 2005, Taiwan produced 70 percent of the world's jazz drums, with Wang Percussion contributing 50 percent of the country's total production. But orders from abroad have been cut in half since 2005, and the downturn is likely to continue, Huang said, adding that there only five major jazz drum manufactures remain in Taiwan, and two of them are likely to move to China soon.

"In the early days, Taiwan was the world's number one guitar exporter, but now all the manufacturers have already moved to China. This is now happening with the jazz drum industry," said Wang Wei-pin (王蔚賓), whose father founded Wang Percussion.

International jazz drum brands have also set up their own factories in China to capitalize on its cheap labor and abundant resources. Huang said Wang Percussion's long-term partner Tama copied his company's core techniques and started manufacturing jazz drums at their own factory in China. But much to their surprise, Huang said, Tama's market penetration has dropped ever since.

"Tama thought they could duplicate Wang Percussion in China and didn't succeed. What they didn't realize is that it's the Taiwanese experience they need to duplicate. The flexibility of local SMEs that comes from their networks of outsourcing and their complete supply chains is not something you can replicate in a short period of time," Huang said.

In 2000, Wang Percussion reinvented itself once again, this time making the shift from OEM to original design manufacturing (ODM). The company created two brand names for its products — DJ, for drum sets and percussion instruments, and WP, for xylophones, marimbas and glockenspiels. But unlike Taiwan's information technology sector, which has long enjoyed the full attention of the national government, local SMEs like Wang Percussion have had to rely on their own acumen when it comes to taking the cautious steps toward branding.

"Without any help from the outside, SMEs tends to adopt a conservative attitude when it comes to brand-building since they don't have the money and resources to fail," Huang said.

The son of a local blue-collar family who obtained a doctorate in economics in the UK, Huang, 33, believes local businesses have the potential to make a successful shift from OEM to ODM.

Recalling how his father came to own a machinery factory after starting out as a motorcycle repairman, Huang said SMEs are strong because they cooperate with each other. "People from my father's generation helped each other out, even when they made the same products," he explained. "Taiwan's SMEs are like amoebas. They are small, flexible, resourceful and can team up with different manufacturers to come up with different products. There is nothing they cannot manage to do."

"Now that we have world-class techniques and products, the next step is to create our own icons [successful brands] through marketing," he added.

Long overdue assistance from the government finally came last year when the Industrial Technology Research Institute (ITRI, 工業技術研究院) initiated a project to help local jazz drum manufacturers develop and share new technologies. But the effort has been met with skepticism from larger businesses such as Wang Percussion.

"Big companies certainly have doubts about joining [ITRI's] program" because they "run the risk of leaking their core-techniques to other manufacturers," Huang said.

He believes that if the government is to come up with feasible plans to assist his industry it should recognize that big and small enterprises have different needs. Small businesses need help with improving manufacturing techniques and enhancing capacity, whereas mature enterprises like Wang Percussion need help with marketing, brand management and client relations.

"I think it is important to build up a dialogue between government offices and the industry so that practical services can meet our demands for a successful industrial shift," Huang said.

Wang Percussion maintains a bilingual Web site at

www.wangpercussion.com.tw

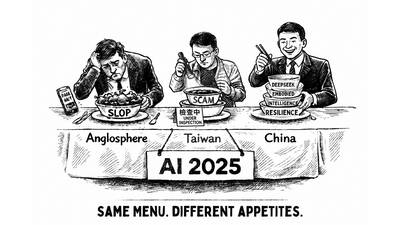

Words of the Year are not just interesting, they are telling. They are language and attitude barometers that measure what a country sees as important. The trending vocabulary around AI last year reveals a stark divergence in what each society notices and responds to the technological shift. For the Anglosphere it’s fatigue. For China it’s ambition. For Taiwan, it’s pragmatic vigilance. In Taiwan’s annual “representative character” vote, “recall” (罷) took the top spot with over 15,000 votes, followed closely by “scam” (詐). While “recall” speaks to the island’s partisan deadlock — a year defined by legislative recall campaigns and a public exhausted

Hsu Pu-liao (許不了) never lived to see the premiere of his most successful film, The Clown and the Swan (小丑與天鵝, 1985). The movie, which starred Hsu, the “Taiwanese Charlie Chaplin,” outgrossed Jackie Chan’s Heart of Dragon (龍的心), earning NT$9.2 million at the local box office. Forty years after its premiere, the film has become the Taiwan Film and Audiovisual Institute’s (TFAI) 100th restoration. “It is the only one of Hsu’s films whose original negative survived,” says director Kevin Chu (朱延平), one of Taiwan’s most commercially successful

In the 2010s, the Communist Party of China (CCP) began cracking down on Christian churches. Media reports said at the time that various versions of Protestant Christianity were likely the fastest growing religions in the People’s Republic of China (PRC). The crackdown was part of a campaign that in turn was part of a larger movement to bring religion under party control. For the Protestant churches, “the government’s aim has been to force all churches into the state-controlled organization,” according to a 2023 article in Christianity Today. That piece was centered on Wang Yi (王怡), the fiery, charismatic pastor of the

The primaries for this year’s nine-in-one local elections in November began early in this election cycle, starting last autumn. The local press has been full of tales of intrigue, betrayal, infighting and drama going back to the summer of 2024. This is not widely covered in the English-language press, and the nine-in-one elections are not well understood. The nine-in-one elections refer to the nine levels of local governments that go to the ballot, from the neighborhood and village borough chief level on up to the city mayor and county commissioner level. The main focus is on the 22 special municipality