Non-woven fabric maker Nan Liu Enterprise Co Ltd (南六企業) yesterday posted revenue of NT$1.61 billion (US$52.2 million) for the first quarter, a 2.3 percent year-on-year decline due to the slow season effect, but analysts said revenue could gain momentum later this year when its new plant in Kaohsiung’s Yanchao District (燕巢) begins operations.

Last quarter’s figure was also lower than the NT$1.69 billion forecast by Taishin Securities Investment Advisory Co (台新投顧), but revenue for the full year is forecast to increase by about 17 percent to NT$7.93 billion following an increase of 5.48 percent last year, Capital Investment Management Corp (群益投顧) said.

The company’s new plant in India is also expected to start contributing revenue next year after construction is completed this year, Capital Investment said.

The plant in Sanand, Gujarat state, is to be the company’s production base in South Asia and Nan Liu is planning to open two production lines of air-through non-woven fabric.

“Nan Liu’s growth momentum may persist due to its capacity expansion and its development of high value-added products,” Capital Investment said in a note.

Through vertical integration, Nan Liu has transformed from a maker of non-woven fabric for various global brands, including Japan’s UniCharm Co and US-based Procter & Gamble Co and Kimberly-Clark Corp, to a supplier of end-market products with high added value.

The company’s revenue breakdown by product for last year was 25 percent for air-through and thermal-bonded non-woven fabric, 23 percent for spunlace non-woven fabric, 40 percent for wet wipes and facial masks, and 12 percent for fabric for surgical gowns.

Nan Liu posted a net profit of NT$592.77 million for last year, up 9.49 percent from NT$541.38 million in 2017, or earnings per share of NT$8.16.

Taiwan’s foreign exchange reserves hit a record high at the end of last month, surpassing the US$600 billion mark for the first time, the central bank said yesterday. Last month, the country’s foreign exchange reserves rose US$5.51 billion from a month earlier to reach US$602.94 billion due to an increase in returns from the central bank’s portfolio management, the movement of other foreign currencies in the portfolio against the US dollar and the bank’s efforts to smooth the volatility of the New Taiwan dollar. Department of Foreign Exchange Director-General Eugene Tsai (蔡炯民)said a rate cut cycle launched by the US Federal Reserve

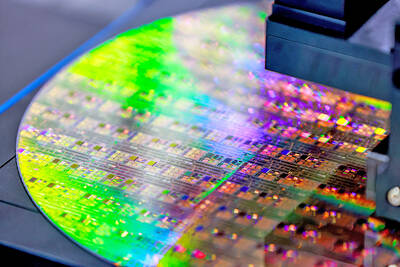

The US government on Wednesday sanctioned more than two dozen companies in China, Turkey and the United Arab Emirates, including offshoots of a US chip firm, accusing the businesses of providing illicit support to Iran’s military or proxies. The US Department of Commerce included two subsidiaries of US-based chip distributor Arrow Electronics Inc (艾睿電子) on its so-called entity list published on the federal register for facilitating purchases by Iran’s proxies of US tech. Arrow spokesman John Hourigan said that the subsidiaries have been operating in full compliance with US export control regulations and his company is discussing with the US Bureau of

Businesses across the global semiconductor supply chain are bracing themselves for disruptions from an escalating trade war, after China imposed curbs on rare earth mineral exports and the US responded with additional tariffs and restrictions on software sales to the Asian nation. China’s restrictions, the most targeted move yet to limit supplies of rare earth materials, represent the first major attempt by Beijing to exercise long-arm jurisdiction over foreign companies to target the semiconductor industry, threatening to stall the chips powering the artificial intelligence (AI) boom. They prompted US President Donald Trump on Friday to announce that he would impose an additional

Pegatron Corp (和碩), a key assembler of Apple Inc’s iPhones, on Thursday reported a 12.3 percent year-on-year decline in revenue for last quarter to NT$257.86 billion (US$8.44 billion), but it expects revenue to improve in the second half on traditional holiday demand. The fourth quarter is usually the peak season for its communications products, a company official said on condition of anonymity. As Apple released its new iPhone 17 series early last month, sales in the communications segment rose sequentially last month, the official said. Shipments to Apple have been stable and in line with earlier expectations, they said. Pegatron shipped 2.4 million notebook