China’s electric vehicle market is so hot that India’s biggest sport utility vehicle maker is angling for a piece of the action.

Mahindra and Mahindra Ltd’s electric car unit is looking for a joint venture partner in China to manufacture and sell electric vehicles in the world’s biggest auto market, Mahindra Reva Electric Vehicles Pvt Ltd CEO Arvind Mathew said.

The company currently sells electric cars in the UK and Indian subcontinent, and is open to offering its power train technology to buyers other than its parent, he said.

“We are continuously looking at the Chinese market to build up scale,” Mathew said in an interview on Thursday last week, declining to say whether Mahindra Electric is already in discussions with local companies. “The Chinese market is an attractive market, as it has all range of electric cars, including two-wheelers, three-wheelers, cars and buses.”

Indian automakers have lagged behind their counterparts in the US, Europe and Japan in cracking the Chinese market, even as Chinese carmakers are venturing abroad into emerging markets.

Mahindra’s South Korean unit, Ssangyong Motor Co, has said it would look to markets such as China to make up for an expected decline in shipments to the UK following the Brexit referendum.

Rival Tata Motors Ltd’s luxury Jaguar Land Rover unit produces the Evoque sport utility vehicle in China through its joint venture with Chery Automobile Co Ltd (奇瑞汽車).

Mahindra’s shares rose as much as 1 percent to 1,387 rupees in Mumbai trading yesterday. The shares have risen 8.7 percent this year.

A successful joint venture in China would pit Mahindra against stiff competition from more than 200 Chinese companies, some backed by the likes of billionaires Terry Gou (郭台銘), Ma Huateng (馬化騰), Jack Ma (馬雲) and Jia Yueting (賈躍亭), all capitalizing on the surge in demand on the back of generous government incentives.

The Indian conglomerate led by chairman Anand Mahindra has interests spanning airplanes, yachts, hotels and residential homes, and last year bought Turin-based Ferrari designer Pininfarina SpA to move beyond its roots in tractors.

China has identified new energy vehicles — which it defines as plug-in hybrids, fuel cell and all-electric vehicles — as a strategic industry to promote its goal of energy security and pollution control.

Beijing has set a target of having 5 million electronic vehicles plying its roads by 2020 and has poured in billions in consumer subsidies, research and development grants and construction of charging infrastructure.

For Mahindra, manufacturing in China is a necessary step, because imported automobiles are subject to a 25 percent duty and do not qualify for government subsidies, making them less attractive against locally produced vehicles.

That is especially critical for mass-market models such as those sold by Mahindra, which compete on price.

China requires foreign automakers establish joint ventures with local partners to manufacture vehicles.

“China is not only a fast-growing electric market, but also highly competitive with strong local electric car companies,” said Kavan Mukhtyar, a management consultant at PricewaterhouseCoopers in Mumbai who has advised auto industry executives. “For Mahindra, what matters most is learning from the Chinese market. Eventually, Chinese electric car companies will enter the Indian market.”

Taiwan’s foreign exchange reserves hit a record high at the end of last month, surpassing the US$600 billion mark for the first time, the central bank said yesterday. Last month, the country’s foreign exchange reserves rose US$5.51 billion from a month earlier to reach US$602.94 billion due to an increase in returns from the central bank’s portfolio management, the movement of other foreign currencies in the portfolio against the US dollar and the bank’s efforts to smooth the volatility of the New Taiwan dollar. Department of Foreign Exchange Director-General Eugene Tsai (蔡炯民)said a rate cut cycle launched by the US Federal Reserve

The US government on Wednesday sanctioned more than two dozen companies in China, Turkey and the United Arab Emirates, including offshoots of a US chip firm, accusing the businesses of providing illicit support to Iran’s military or proxies. The US Department of Commerce included two subsidiaries of US-based chip distributor Arrow Electronics Inc (艾睿電子) on its so-called entity list published on the federal register for facilitating purchases by Iran’s proxies of US tech. Arrow spokesman John Hourigan said that the subsidiaries have been operating in full compliance with US export control regulations and his company is discussing with the US Bureau of

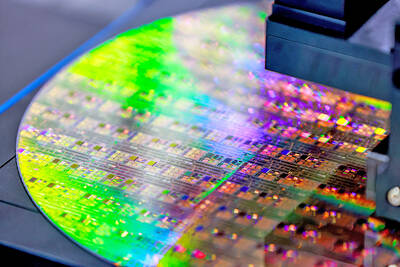

Businesses across the global semiconductor supply chain are bracing themselves for disruptions from an escalating trade war, after China imposed curbs on rare earth mineral exports and the US responded with additional tariffs and restrictions on software sales to the Asian nation. China’s restrictions, the most targeted move yet to limit supplies of rare earth materials, represent the first major attempt by Beijing to exercise long-arm jurisdiction over foreign companies to target the semiconductor industry, threatening to stall the chips powering the artificial intelligence (AI) boom. They prompted US President Donald Trump on Friday to announce that he would impose an additional

Pegatron Corp (和碩), a key assembler of Apple Inc’s iPhones, on Thursday reported a 12.3 percent year-on-year decline in revenue for last quarter to NT$257.86 billion (US$8.44 billion), but it expects revenue to improve in the second half on traditional holiday demand. The fourth quarter is usually the peak season for its communications products, a company official said on condition of anonymity. As Apple released its new iPhone 17 series early last month, sales in the communications segment rose sequentially last month, the official said. Shipments to Apple have been stable and in line with earlier expectations, they said. Pegatron shipped 2.4 million notebook