The 34-year-old Chen Zhen-che (陳振哲) is the brains behind the hot-selling "Magic Bean" canned plants that Japanese toymaker Takara Co marketed last month to capitalize on the selling frenzy of Valentine's Day in Japan.

Unlike other canned plants, Chen's cans are filled with a bacteria-free, chemical substitute for soil.

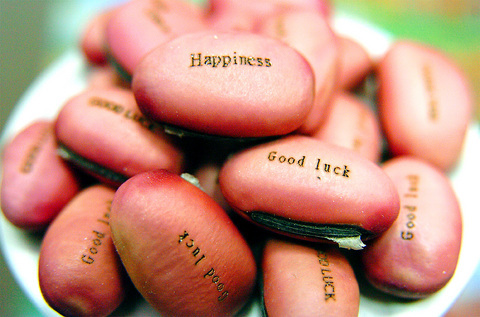

The plants sprout in five to seven days and have sweet messages on the bean's surface.

PHOTO: GEORGE TSORNG, TAIPEI TIMES

"People were curious about the beans, and a product like this usually meets with a high demand in the market," Chen said in a recent interview at his small factory in the Hsiko Township of Chiayi County in southern Taiwan.

The well-wishing messages are "Happiness," "Good luck," "I love you," or "I miss you," featured on one side of the bean such as a graphic of an arrow piercing two hearts on the other.

"Few people believe the product is actually made here in Taiwan; they think it is imported from Japan or Korea," Chen said with pride.

PHOTO: GEORGE TSORNG, TAIPEI TIMES

The son of a farmer, Chen grew up in Chiayi and was a farmer, hair stylist and even ran a small wholesale stationery company.

But Chen says he always had a passion for flora and plants.

Chen said he first embarked on the idea of developing canned plants about five years ago.

He selected different plant species, put them inside a can and sealed them in a vacuum.

Then he distributed them at night markets and on the Internet.

The market response was very positive as little effort is required to take care of the plants, Chen said.

His plants have a high budding rate, and inside the can the fertilizer has been allocated according to the nutrition the plant will need to grow.

"What the customers need to do is read the directions on temperature, sunlight and water. Then they can observe the plant's budding, growth and blossoming in stages," he said.

His company Yu Chyu Co (羽鉅) has developed a lineup of 43 different plant products, ranging from carnations and sunflowers to lavender and tulips.

His overseas markets include Europe, South Korea, Japan, the US and China. Japan and Europe remain the biggest markets for Chen's products, while demand from China and South Korea has been increasing substantially.

But Chen has faced competition from rivals. In 2002, Chen got the idea of presenting plants with blessings on them.

"I thought of sculpting the messages on the bean. I thought of writing and even tried to iron the messages on it ... I tried every possible way you could think of to make it happen but I failed," Chen recalled.

After a year of trying, he at last selected the swordbean (Canavalia gladiata) as the most suitable bean, and found ways to inscribe the messages using a laser beam.

Chen named it the `Jack bean' after the fairy tale story `Jack and the beanstalk,' in hopes that whomever owns the bean will be as lucky as Jack is in the tale.

But in reality, Chen wasn't as lucky as he thought. His company faced great losses as a result of an increased bout of counterfeiting in China and South Korea.

"There are many fake `magic bean' products in those two countries," Chen said.

"For instance, we applied for a patent on our canned plants with the Chinese authorities in 1999, but we saw some Chinese companies had registered patents for the fake products there in 2002," he said.

Worst of all, several of his previous distributors in China later turned out to be his competitors after they learned how to use a laser beam in order to inscribe the messages.

"It took me a year or two to solve the problem. But Chinese copycats just stole the idea without having made any of the effort," he said.

While taking legal action against counterfeiters, Chen decided last year to create a new product, a "Magic egg," to stay ahead of his rivals.

"For a small company like us, we just don't have enough capital to file lawsuits against so many counterfeiters. But I know what I can do -- keep developing new products and always move our technology forward," he said.

The new products also have a bean inside, sprout and crack open through an egg, and show similarly sweet messages.

To make it possible, Chen said he first took an egg yolk and put the bean inside as well as the fertilizer, but he soon found the process was too time-consuming and that the budding rate was too low.

He then substituted a calcium-made fake egg and turned to academics for help in increasing the budding rate.

By collaborating with a horticulture professor at National Chiayi University, Shen Rong-shou (沈榮壽), who specializes in seed breeding, Chen solved the low budding rate problem.

This time the new product attracted interest from another Japanese toymaker -- Tomy Co's. Tomy also placed orders with Yu Chyu for Valentine's Day.

"Besides Tomy, we also saw a strong demand in other markets, including Taiwan," said Chen, adding that the company will see revenues double to about NT$80 million this year.

In 2003, Yu Chyu had an output of 100,000 canned plants per month. At the time, the company hired about 20 people.

But the company has now doubled its monthly output to 200,000 cans, and has also increased its manpower to around 100 people.

Since the collaboration with academics proved successful, Chen said he is now working on another new product.

"It is a plant that grows inside the can but needs no watering. The vacuum-sealed can will work like a self-developed life cycle," Chen said.

He declined to talk more about the new products, but they will debut in the spring of next year.

Macronix International Co (旺宏), the world’s biggest NOR flash memory supplier, yesterday said it would spend NT$22 billion (US$699.1 million) on capacity expansion this year to increase its production of mid-to-low-density memory chips as the world’s major memorychip suppliers are phasing out the market. The company said its planned capital expenditures are about 11 times higher than the NT$1.8 billion it spent on new facilities and equipment last year. A majority of this year’s outlay would be allocated to step up capacity of multi-level cell (MLC) NAND flash memory chips, which are used in embedded multimedia cards (eMMC), a managed

CULPRITS: Factors that affected the slip included falling global crude oil prices, wait-and-see consumer attitudes due to US tariffs and a different Lunar New Year holiday schedule Taiwan’s retail sales ended a nine-year growth streak last year, slipping 0.2 percent from a year earlier as uncertainty over US tariff policies affected demand for durable goods, data released on Friday by the Ministry of Economic Affairs showed. Last year’s retail sales totaled NT$4.84 trillion (US$153.27 billion), down about NT$9.5 billion, or 0.2 percent, from 2024. Despite the decline, the figure was still the second-highest annual sales total on record. Ministry statistics department deputy head Chen Yu-fang (陳玉芳) said sales of cars, motorcycles and related products, which accounted for 17.4 percent of total retail rales last year, fell NT$68.1 billion, or

In the wake of strong global demand for AI applications, Taiwan’s export-oriented economy accelerated with the composite index of economic indicators flashing the first “red” light in December for one year, indicating the economy is in booming mode, the National Development Council (NDC) said yesterday. Moreover, the index of leading indicators, which gauges the potential state of the economy over the next six months, also moved higher in December amid growing optimism over the outlook, the NDC said. In December, the index of economic indicators rose one point from a month earlier to 38, at the lower end of the “red” light.

In Italy’s storied gold-making hubs, jewelers are reworking their designs to trim gold content as they race to blunt the effect of record prices and appeal to shoppers watching their budgets. Gold prices hit a record high on Thursday, surging near US$5,600 an ounce, more than double a year ago as geopolitical concerns and jitters over trade pushed investors toward the safe-haven asset. The rally is putting undue pressure on small artisans as they face mounting demands from customers, including international brands, to produce cheaper items, from signature pieces to wedding rings, according to interviews with four independent jewelers in Italy’s main