Almost 15 years ago, Richard Livengood, a researcher for Intel, used an exotic machine known as a focused ion beam to painstakingly deposit a missing wire on the surface of a 486-microprocessor chip.

The chip was then placed into a personal computer, which, to the astonishment of Livengood and a small group of Intel engineers, booted Microsoft's Windows operating system without a hitch.

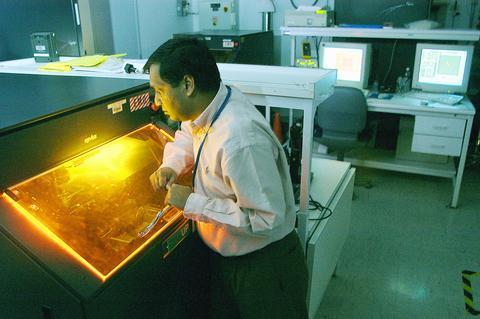

PHOTO: NY TIMES

The technique, now referred to as silicon nanosurgery and routinely used at nine Intel chip factories around the world, has completely transformed the way modern computer chips are developed.

Around the Clock

In a building next to Intel's corporate headquarters here, the focused ion beam technology is now employed -- often around the clock -- as part of an arsenal of microimaging and "surgical" tools used to locate design flaws and performance bottlenecks and make changes in circuit wires that are frequently no more than several hundred atoms in width.

In a cluster of windowless rooms known as the debug lab, the company also uses lasers and photo detectors, often aimed at single transistors.

One of the newest machines, using what is called laser-assisted device alteration, makes it possible to change the speed of the tiny switches that make up a silicon chip. This allows Intel chip designers to quickly fine-tune circuits to generate more speed from their microprocessors.

Similar systems are widely used throughout the semiconductor industry today to accelerate the time it takes to go from prototype chips to manufacturing.

Rather than keeping the technologies it pioneers proprietary, Intel often licenses them to semiconductor equipment makers in an effort to keep the industry advancing uniformly as well as to ensure a less-expensive supply of the multimillion-dollar machines.

At the same time, Intel tries to keep some technologies in reserve to maintain a lead in an industry in which a technology generation lasts about two years.

Molecular-Scale

The company's silicon surgeons are proof that chip makers are now within a decade of creating electronic devices made from molecular-scale components.

"We've moved well into the nano world," said Livengood, who has worked at Intel for 17 years.

Techniques for peering into semiconductor chips date to the early 1980s, when Intel scientists pioneered an approach known as voltage contrast technology.

Timing Problems

By scanning an electron beam across the top of a running computer chip, they were able to watch each transistor and wire in the chip switch on and off. It made it possible to look for hard-to-diagnose timing problems, like a transistor that was turning on and off too slowly.

During that decade, however, the industry was forced to find new techniques when it developed sophisticated methods for packaging chips, known as "flip chip" modules. This advance made it possible to attach many more wires to each chip to move data in and out more quickly.

The task of looking inside working chips that had been turned upside down and sealed shut was much more complicated. To gain access to the transistors again, Livengood's researchers developed an approach based on etching away most of the back of the chip until only an ultrathin sheet of silicon was left. It acted as a window, making it possible to use ion beams and lasers to see the transistors as they turned on and off.

The researchers were then able to devise ways to use the ion beams to cut holes less than a micron in diameter through the back of the chip. The holes make it possible to both cut metal wires and add new ones inside the chip.

On some occasions, Intel technicians even fashion ultrasmall capacitors or change the width and thickness of the metal lines to speed up or slow down the switching speed of transistors.

Tweaking

The tools are used routinely now as part of the process of tuning new chips as they are readied for manufacturing. Livengood estimated that it was possible to increase speeds as much as 20 percent by tweaking individual transistors in a process similar to that of a piano tuner adjusting different wires on a piano.

Recently, Intel's president, Paul S. Otellini, said the company was changing its strategy to focus less on pure chip speed and more on adding features to its future microprocessors.

That will not give Livengood's design team any chance to relax, however.

"Moore's Law hasn't changed," he said, referring to the industry's track record of constantly shrinking the size of transistors.

The CIA has a message for Chinese government officials worried about their place in Chinese President Xi Jinping’s (習近平) government: Come work with us. The agency released two Mandarin-language videos on social media on Thursday inviting disgruntled officials to contact the CIA. The recruitment videos posted on YouTube and X racked up more than 5 million views combined in their first day. The outreach comes as CIA Director John Ratcliffe has vowed to boost the agency’s use of intelligence from human sources and its focus on China, which has recently targeted US officials with its own espionage operations. The videos are “aimed at

STEADFAST FRIEND: The bills encourage increased Taiwan-US engagement and address China’s distortion of UN Resolution 2758 to isolate Taiwan internationally The Presidential Office yesterday thanked the US House of Representatives for unanimously passing two Taiwan-related bills highlighting its solid support for Taiwan’s democracy and global participation, and for deepening bilateral relations. One of the bills, the Taiwan Assurance Implementation Act, requires the US Department of State to periodically review its guidelines for engagement with Taiwan, and report to the US Congress on the guidelines and plans to lift self-imposed limitations on US-Taiwan engagement. The other bill is the Taiwan International Solidarity Act, which clarifies that UN Resolution 2758 does not address the issue of the representation of Taiwan or its people in

US Indo-Pacific Commander Admiral Samuel Paparo on Friday expressed concern over the rate at which China is diversifying its military exercises, the Financial Times (FT) reported on Saturday. “The rates of change on the depth and breadth of their exercises is the one non-linear effect that I’ve seen in the last year that wakes me up at night or keeps me up at night,” Paparo was quoted by FT as saying while attending the annual Sedona Forum at the McCain Institute in Arizona. Paparo also expressed concern over the speed with which China was expanding its military. While the US

SHIFT: Taiwan’s better-than-expected first-quarter GDP and signs of weakness in the US have driven global capital back to emerging markets, the central bank head said The central bank yesterday blamed market speculation for the steep rise in the local currency, and urged exporters and financial institutions to stay calm and stop panic sell-offs to avoid hurting their own profitability. The nation’s top monetary policymaker said that it would step in, if necessary, to maintain order and stability in the foreign exchange market. The remarks came as the NT dollar yesterday closed up NT$0.919 to NT$30.145 against the US dollar in Taipei trading, after rising as high as NT$29.59 in intraday trading. The local currency has surged 5.85 percent against the greenback over the past two sessions, central