In a northern Tunisian olive grove, Yassine Khelifi’s small workshop hums as a large machine turns olive waste into a valuable energy source in a country heavily reliant on imported fuel.

Holding a handful of compacted olive residue — a thick paste left over from oil extraction — Khelifi said: “This is what we need today. How can we turn something worthless into wealth?”

For generations, rural households in Tunisia have burned olive waste for cooking and heating, or used it as animal feed.

Photo: AFP

The International Olive Council estimated Tunisia would be the world’s third-largest olive oil producer this year, with an expected yield of 340,000 tonnes.

The waste generated by the oil extraction is staggering.

Khelifi, an engineer who grew up in a family of farmers, founded Bioheat in 2022 to tackle the issue. He recalled watching workers in olive mills use the olive residue as fuel.

Photo: AFP

“I always wondered how this material could burn for so long without going out,” he said. “That’s when I asked myself: ‘Why not turn it into energy?’”

Beyond profit, Khelifi hopes his start-up helps “reduce the use of firewood as the country faces deforestation and climate change.”

At his workshop, employees transport truckloads of olive waste, stacking it high before feeding it into the processing machines.

The material is then compacted into cylindrical briquettes and left to dry for a month under the sun and in greenhouses before its packaging and sale.

Khelifi began developing his idea in 2018 after he traveled across Europe searching for a machine to turn the olive paste into long-burning fuel.

Unable to find the right technology, he returned to Tunisia and spent four years experimenting with various motors and mechanical parts.

By 2021, he had developed a machine that produced briquettes with just 8 percent moisture.

This amount significantly reduces carbon emissions compared with firewood, which requires months of drying and often retains more than double the amount of moisture, he said.

Bioheat found a market among Tunisian restaurants, guesthouses and schools in underdeveloped regions, where winter temperatures at times drop below freezing.

However, the majority of its production — about 60 percent — is set for exports to France and Canada, Khelifi said.

The company now employs 10 people and is targeting production of 600 tonnes of briquettes this year, he added.

Selim Sahli, 40, who runs a guesthouse, said he replaced traditional firewood with Khelifi’s briquettes for heating and cooking.

“It’s an eco-friendly and cost-effective alternative,” he said. “It’s clean, easy to use, and has reduced my heating costs by a third.”

Mohamed Harrar, the owner of a pizza shop on the outskirts of Tunis, praised the briquettes for reducing smoke emissions, which he said previously irritated his neighbors.

“Besides, this waste carries the soul of Tunisian olives and gives the pizza a special flavor,” he added.

Given Tunisia’s significant olive oil production, its waste byproducts pose both a challenge and an opportunity.

Noureddine Nasr, an agricultural and rural development expert, said about 600,000 tonnes of olive waste is produced annually.

“Harnessing this waste can protect the environment, create jobs and generate wealth,” he said.

Nasr believes repurposing olive waste could also help alleviate Tunisia’s heavy dependence on imported fuel.

The country imports more than 60 percent of its energy needs, a reliance that widens its trade deficit and strains government subsidies, a 2023 World Bank report said.

Fuel and gas shortages are common during winter, particularly in Tunisia’s northwestern provinces, where households struggle to keep warm.

Redirecting agricultural waste into alternative energy sources could ease this burden.

Yet for entrepreneurs like Khelifi, launching a start-up in Tunisia is fraught with challenges.

“The biggest hurdle was funding,” he said, lamenting high-interest bank loans.

“It felt like walking on a road full of potholes,” he said.

However, now his goal is “to leave my mark as a key player in Tunisia’s transition to clean energy,” he said. “And hopefully, the world’s, too.”

SETBACK: Apple’s India iPhone push has been disrupted after Foxconn recalled hundreds of Chinese engineers, amid Beijing’s attempts to curb tech transfers Apple Inc assembly partner Hon Hai Precision Industry Co (鴻海精密), also known internationally as Foxconn Technology Group (富士康科技集團), has recalled about 300 Chinese engineers from a factory in India, the latest setback for the iPhone maker’s push to rapidly expand in the country. The extraction of Chinese workers from the factory of Yuzhan Technology (India) Private Ltd, a Hon Hai component unit, in southern Tamil Nadu state, is the second such move in a few months. The company has started flying in Taiwanese engineers to replace staff leaving, people familiar with the matter said, asking not to be named, as the

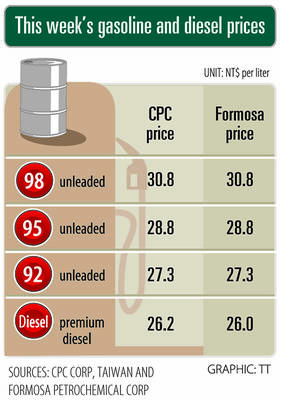

The prices of gasoline and diesel at domestic fuel stations are to rise NT$0.1 and NT$0.4 per liter this week respectively, after international crude oil prices rose last week, CPC Corp, Taiwan (台灣中油) and Formosa Petrochemical Corp (台塑石化) announced yesterday. Effective today, gasoline prices at CPC and Formosa stations are to rise to NT$27.3, NT$28.8 and NT$30.8 per liter for 92, 95 and 98-octane unleaded gasoline respectively, the companies said in separate statements. The price of premium diesel is to rise to NT$26.2 per liter at CPC stations and NT$26 at Formosa pumps, they said. The announcements came after international crude oil prices

DOLLAR SIGNS: The central bank rejected claims that the NT dollar had appreciated 10 percentage points more than the yen or the won against the greenback The New Taiwan dollar yesterday fell for a sixth day to its weakest level in three months, driven by equity-related outflows and reactions to an economics official’s exchange rate remarks. The NT dollar slid NT$0.197, or 0.65 percent, to close at NT$30.505 per US dollar, central bank data showed. The local currency has depreciated 1.97 percent so far this month, ranking as the weakest performer among Asian currencies. Dealers attributed the retreat to foreign investors wiring capital gains and dividends abroad after taking profit in local shares. They also pointed to reports that Washington might consider taking equity stakes in chipmakers, including Taiwan Semiconductor

A German company is putting used electric vehicle batteries to new use by stacking them into fridge-size units that homes and businesses can use to store their excess solar and wind energy. This week, the company Voltfang — which means “catching volts” — opened its first industrial site in Aachen, Germany, near the Belgian and Dutch borders. With about 100 staff, Voltfang says it is the biggest facility of its kind in Europe in the budding sector of refurbishing lithium-ion batteries. Its CEO David Oudsandji hopes it would help Europe’s biggest economy ween itself off fossil fuels and increasingly rely on climate-friendly renewables. While