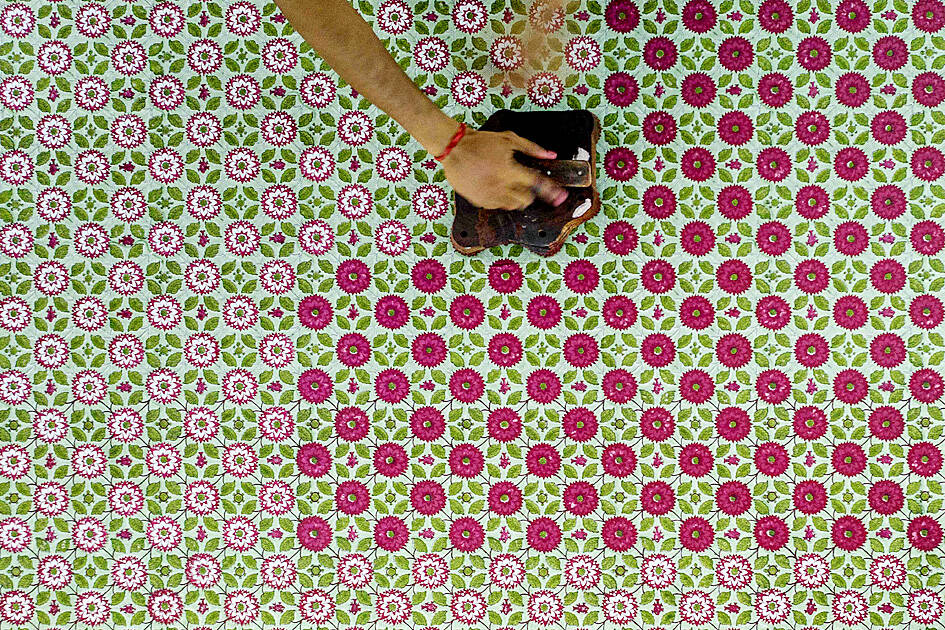

Textiles designer Brigitte Singh lovingly lays out a piece of cloth embossed with a red poppy plant she said was probably designed for Mughal emperor Shah Jahan, builder of the Taj Mahal, four centuries ago.

For Singh — who moved from France to India 42 years ago and married into a maharaja’s family — this exquisite piece remains the ever-inspiring heart of her studio’s mission.

The 67-year-old is striving to keep alive the art of block printing, which flourished in the 16th and 17th centuries under the conquering, but sophisticated, Mughal dynasty that then ruled India.

Photo: AFP

“I was the first to give a renaissance to this kind of Mughal design,” Singh said in her traditional printing workshop in Rajasthan.

Having studied decorative arts in Paris, Singh arrived aged 25 in 1980 in western India’s Jaipur, the “last bastion” of the technique of using carved blocks of wood to print patterns on material.

“I dreamed of practicing [miniature art] in Isfahan, but the Ayatollahs had just arrived in Iran [in the Islamic revolution of 1979]. Or Herat, but the Soviets had just arrived in Afghanistan,” she said.

Photo: AFP

“So by default, I ended up in Jaipur,” she said.

A few months after arriving, Singh was introduced to a member of the local nobility who was related to the maharaja of Rajasthan. They married in 1982.

At first, Singh still hoped to try her hand at miniature painting, but after scouring the city for traditional paper to work on, she came across workshops using block printing.

Photo: AFP

“I fell into the magic potion and could never go back,” she said. She started by making just a few scarves, and when she passed through London two years later, gave them as presents to friends who were connoisseurs of Indian textiles. Bowled over, they persuaded her to show them to Colefax and Fowler, the storied British interior decorations firm.

“The next thing I knew, I was on my way back to India with an order for printed textiles,” she said.

For the next two decades, she worked with a “family of printers” in the city before building her own studio in nearby Amber — a stone’s throw from Jaipur’s famous fort.

It was her father-in-law, a major collector of Rajasthan miniatures, who gave her the Mughal-era poppy cloth connected to Shah Jahan.

Her reproduction of that print was a huge success the world over, proving especially popular with Indian, British and Japanese clients.

In 2014, she made a Mughal poppy print quilted coat, called an atamsukh — meaning “comfort of the soul” — that was later acquired by the Victoria and Albert Museum in London.

Another piece of her work is in the collection of the Metropolitan Art Museum in New York.

Singh starts her creative process by handing precise paintings to her sculptor, Rajesh Kumar, who then painstakingly chisels the designs onto blocks of wood.

“We need a remarkable sculptor, with a very serious eye,” she said. “The carving of the wood blocks is the key. This tool has the sophistication of simplicity.”

Kumar makes several identical blocks for each color used in each printed fabric.

“The poppy motif, for example, has five colors. I had to make five blocks,” he said. “It took me 20 days.”

At Singh’s workshop, six employees work on pieces of cloth laid out on tables 5m long.

They dip the blocks in dye, place them carefully on the cloth, push down and tap.

The work is slow and intricate, producing no more than 40m of material every day.

Her workshop makes everything from quilts to curtains and rag dolls to shoes.

Singh just finished another atamsukh for a prince in Kuwait.

“The important thing is to keep the know-how alive,” she said. “More precious than the product, the real treasure is the savoir faire.”

Sweeping policy changes under US Secretary of Health and Human Services Robert F. Kennedy Jr are having a chilling effect on vaccine makers as anti-vaccine rhetoric has turned into concrete changes in inoculation schedules and recommendations, investors and executives said. The administration of US President Donald Trump has in the past year upended vaccine recommendations, with the country last month ending its longstanding guidance that all children receive inoculations against flu, hepatitis A and other diseases. The unprecedented changes have led to diminished vaccine usage, hurt the investment case for some biotechs, and created a drag that would likely dent revenues and

Global semiconductor stocks advanced yesterday, as comments by Nvidia Corp chief executive officer Jensen Huang (黃仁勳) at Davos, Switzerland, helped reinforce investor enthusiasm for artificial intelligence (AI). Samsung Electronics Co gained as much as 5 percent to an all-time high, helping drive South Korea’s benchmark KOSPI above 5,000 for the first time. That came after the Philadelphia Semiconductor Index rose more than 3 percent to a fresh record on Wednesday, with a boost from Nvidia. The gains came amid broad risk-on trade after US President Donald Trump withdrew his threat of tariffs on some European nations over backing for Greenland. Huang further

CULPRITS: Factors that affected the slip included falling global crude oil prices, wait-and-see consumer attitudes due to US tariffs and a different Lunar New Year holiday schedule Taiwan’s retail sales ended a nine-year growth streak last year, slipping 0.2 percent from a year earlier as uncertainty over US tariff policies affected demand for durable goods, data released on Friday by the Ministry of Economic Affairs showed. Last year’s retail sales totaled NT$4.84 trillion (US$153.27 billion), down about NT$9.5 billion, or 0.2 percent, from 2024. Despite the decline, the figure was still the second-highest annual sales total on record. Ministry statistics department deputy head Chen Yu-fang (陳玉芳) said sales of cars, motorcycles and related products, which accounted for 17.4 percent of total retail rales last year, fell NT$68.1 billion, or

HSBC Bank Taiwan Ltd (匯豐台灣商銀) and the Taiwan High Prosecutors Office recently signed a memorandum of understanding (MOU) to enhance cooperation on the suspicious transaction analysis mechanism. This landmark agreement makes HSBC the first foreign bank in Taiwan to establish such a partnership with the High Prosecutors Office, underscoring its commitment to active anti-fraud initiatives, financial inclusion, and the “Treating Customers Fairly” principle. Through this deep public-private collaboration, both parties aim to co-create a secure financial ecosystem via early warning detection and precise fraud prevention technologies. At the signing ceremony, HSBC Taiwan CEO and head of banking Adam Chen (陳志堅)