Singapore-based DBS Bank Ltd (星展銀行) has opened its third financial technology (fintech) research and development (R&D) center in the world in Taiwan, company executives announced at a news conference yesterday.

DBS Bank Taiwan (星展台灣) general manager Lim Him-chuan (林鑫川) said that the COVID-19 pandemic has increased demand for digital financial services, and the bank decided to set up an R&D center in Taiwan to build a lead over its local rivals in fintech development.

DBS wants to take advantage of Taiwan’s large pool of technology professionals to integrate its financial resources and provide fast and comprehensive services to its clients, Lim said.

Photo: Lee Chin-hui, Taipei Times

The bank’s first fintech R&D center was set up in Singapore, where it is headquartered, and the second was established in India because of that country’s big pool of tech experts, DBS Taiwan technology head Rock Tsai (蔡祈岩) said.

DBS chose Taiwan for its third center because it has done well in dealing with the pandemic and, more importantly, it is a high-tech manufacturing base for many global brands, Tsai said.

The new center aims to recruit at least 30 information technology experts in Taiwan by the end of the second quarter, the bank said.

It will be looking for software engineers and tech professionals who are familiar with Java, C#, Python and JavaScript programming, as well as apps designed for iOS and Android smartphone operating systems.

The bank’s recruitment drive will focus on giving students greater exposure to the fintech field, as most information technology and information engineering graduates in Taiwan have their sights set on careers in science parks and semiconductor companies, Tsai said.

If Taiwan hopes to become an international financial hub, it has to cultivate experts in this field, he said.

Real estate agent and property developer JSL Construction & Development Co (愛山林) led the average compensation rankings among companies listed on the Taiwan Stock Exchange (TWSE) last year, while contract chipmaker Taiwan Semiconductor Manufacturing Co (TSMC, 台積電) finished 14th. JSL Construction paid its employees total average compensation of NT$4.78 million (US$159,701), down 13.5 percent from a year earlier, but still ahead of the most profitable listed tech giants, including TSMC, TWSE data showed. Last year, the average compensation (which includes salary, overtime, bonuses and allowances) paid by TSMC rose 21.6 percent to reach about NT$3.33 million, lifting its ranking by 10 notches

SEASONAL WEAKNESS: The combined revenue of the top 10 foundries fell 5.4%, but rush orders and China’s subsidies partially offset slowing demand Taiwan Semiconductor Manufacturing Co (TSMC, 台積電) further solidified its dominance in the global wafer foundry business in the first quarter of this year, remaining far ahead of its closest rival, Samsung Electronics Co, TrendForce Corp (集邦科技) said yesterday. TSMC posted US$25.52 billion in sales in the January-to-March period, down 5 percent from the previous quarter, but its market share rose from 67.1 percent the previous quarter to 67.6 percent, TrendForce said in a report. While smartphone-related wafer shipments declined in the first quarter due to seasonal factors, solid demand for artificial intelligence (AI) and high-performance computing (HPC) devices and urgent TV-related orders

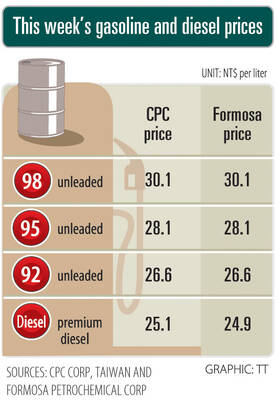

Prices of gasoline and diesel products at domestic fuel stations are this week to rise NT$0.2 and NT$0.3 per liter respectively, after international crude oil prices increased last week, CPC Corp, Taiwan (台灣中油) and Formosa Petrochemical Corp (台塑石化) said yesterday. International crude oil prices last week snapped a two-week losing streak as the geopolitical situation between Russia and Ukraine turned increasingly tense, CPC said in a statement. News that some oil production facilities in Alberta, Canada, were shut down due to wildfires and that US-Iran nuclear talks made no progress also helped push oil prices to a significant weekly gain, Formosa said

MINERAL DIPLOMACY: The Chinese commerce ministry said it approved applications for the export of rare earths in a move that could help ease US-China trade tensions Chinese Vice Premier He Lifeng (何立峰) is today to meet a US delegation for talks in the UK, Beijing announced on Saturday amid a fragile truce in the trade dispute between the two powers. He is to visit the UK from yesterday to Friday at the invitation of the British government, the Chinese Ministry of Foreign Affairs said in a statement. He and US representatives are to cochair the first meeting of the US-China economic and trade consultation mechanism, it said. US President Donald Trump on Friday announced that a new round of trade talks with China would start in London beginning today,